Super Austenitic Ball Valves exhibit great resistance to chloride pitting and crevice corrosion because of high molybdenum content (>6%) and nitrogen additions.These steels approach the performance of highly corrosion resistant nickel based alloys at a significant lower cost.

best super Austenitic Ball Valve Manufacturer in India Qaswa Engineering Pvt Ltd

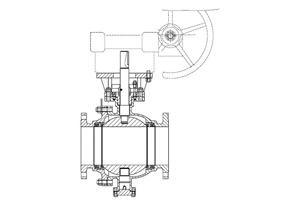

Characteristics of Super Austenitic Ball Valves

Qaswa Engineering Pvt Ltd Super Austenitic Ball Valves combine with 904L, 254SMO, AL-6XN, Alloy 20 etc.

- 904L (N08904,14539) super austenitic stainless steel contains 14.0-18.0% chromium, 24.0-26.0% nickel, 4.5% molybdenum. 904L super austenitic stainless steel is a low carbon, high nickel, molybdenum austenitic stainless steel, which is a proprietary material imported from France H-S. It has good activation-passivation conversion ability and excellent corrosion resistance in non-oxidizing acids such as sulfuric acid, acetic acid, formic acid and phosphoric acid. It has good activation-passivation transformation ability, excellent corrosion resistance, good corrosion resistance in non-oxidizing acids such as sulfuric acid, acetic acid, formic acid and phosphoric acid, good resistance to pitting corrosion in neutral media containing chloride ions, and good resistance to crevice corrosion and stress corrosion.

- 254SMO (UNS S31254) is a high corrosion resistant austenitic stainless steel with high nickel, high chromium, high molybdenum alloy design, and provides excellent corrosion resistance in severe corrosion environments such as high-temperature seawater.

- AL-6XN is a typical 6 molybdenum (high molybdenum content 6.3%) super austenitic stainless steel. The resistance to chloride pitting, crevice corrosion and stress corrosion is better than Series 3 stainless steels and is less costly than corrosion-resistant nickel based alloys. Good corrosion resistance in severe corrosive environments, suitable for high chloride aqueous solutions and chloride corrosion environments. For use in a variety of high chloride environments: bleach (sodium hypochlorite, chlorine dioxide), halogens and chemicals with high salt or seawater content.

- Alloy 20 is stainless steel with extremely high corrosion resistance to sulfuric acid.

- These types of industrial valve can be used in a wide range of sulfuric acid environments, including high concentration, high-temperature environments. It possesses excellent intergranular corrosion resistance and stress corrosion cracking resistance.

Application of Super Austenitic Ball Valves

- This hand ball valve can be used for pulp & paper

- The hand operated valve can be used for wastewater treatment

- Chemical

Comments