What Is Aluminum Safety Grating?

Aluminum safety grating is a structural flooring and decking product designed to maximize slip resistance and load-bearing capacity. Unlike plain sheets or panels, it is engineered with perforations, serrations, or patterns that provide traction in multiple directions. Its lightweight structure makes it easier to transport and install, while its corrosion resistance ensures long-lasting use in harsh environments.

Key attributes of aluminum safety grating include:

- Strength-to-weight ratio – lighter than steel but capable of supporting heavy loads.

- Non-slip surface – serrations and perforations increase traction.

- Corrosion resistance – suitable for wet, marine, or chemical environments.

- Versatility – applicable in industrial flooring, walkways, stairs, and architectural decoration.

Companies such as Huijin Metal Mesh highlight its diverse applications, reinforcing why aluminum safety grating remains a leading choice in safety flooring solutions.

Why Is Aluminum Safety Grating Important for Safety?

The primary purpose of aluminum safety grating is to reduce workplace accidents. Slips, trips, and falls remain one of the leading causes of injuries in industrial settings. By using grating with raised patterns, workers are provided with stable footing even in challenging conditions such as rain, snow, oil spills, or dusty environments.

Additional safety benefits include:

- Drainage – perforations allow liquids and debris to pass through.

- Visibility – open patterns can reduce shadowing and improve lighting on platforms.

- Durability – aluminum resists corrosion, ensuring the grating retains its structural integrity.

- Versatility – it is used in stairs, ramps, walkways, catwalks, and mezzanines.

This makes aluminum safety grating an integral part of modern safety engineering, protecting workers, pedestrians, and even architectural users.

What Are the Main Types of Aluminum Safety Grating?

Aluminum safety grating is manufactured in several designs, each optimized for different environments and applications. Below are the most widely used types:

Diamond Grip Aluminum Safety Grating

Diamond grip grating features raised diamond-shaped dimples that create multidirectional traction. Its surface prevents slips even when exposed to water, oil, or mud. Commonly used in industrial walkways and catwalks, it offers a reliable balance of safety and load capacity.

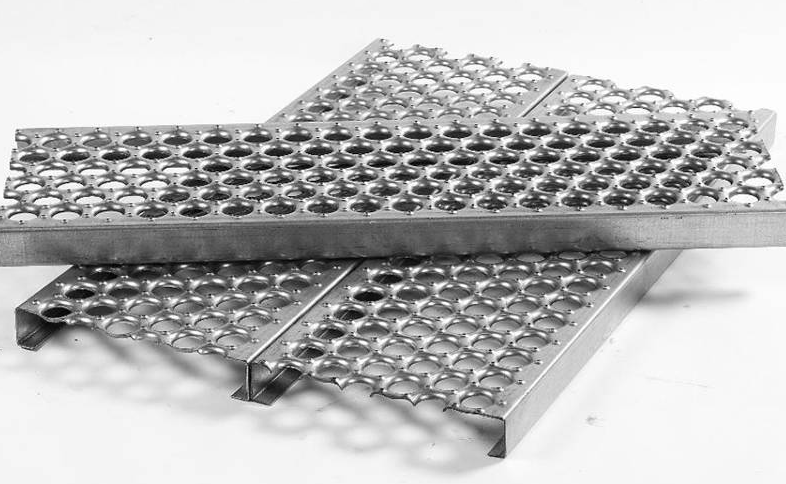

O-Grip Aluminum Safety Grating

O-grip grating contains round openings with raised edges, providing slip resistance while allowing liquids and debris to fall through. It is particularly effective in outdoor environments, food processing areas, and oil platforms.

Traction Tread Aluminum Safety Grating

Traction tread is characterized by closely spaced perforations that provide consistent grip. Its fine pattern makes it ideal for public spaces, stairs, ramps, and areas where high pedestrian safety is required. It also prevents small items or heels from getting stuck.

Bar Aluminum Safety Grating

Bar grating uses parallel load-bearing bars joined by crossbars. It is strong and durable, capable of supporting heavy loads. This type is often installed in factories, warehouses, and heavy-duty platforms where equipment or vehicles operate.

Swage-Locked Aluminum Safety Grating

Swage-locked grating is produced by mechanically locking crossbars into bearing bars. It is lightweight but highly durable, distributing loads evenly across the structure. It is widely used in elevated walkways, mezzanines, and industrial platforms.

Riveted Aluminum Safety Grating

This traditional type uses rivets to fasten bearing bars and crossbars together, creating an exceptionally strong product. It is suitable for high-load environments such as bridges, shipyards, and transportation terminals.

Serrated Aluminum Safety Grating

Serrated surfaces include jagged edges that maximize traction. They are particularly useful in icy, snowy, or oily environments where slip prevention is critical.

Where Is Aluminum Safety Grating Used?

Aluminum safety grating is employed in both industrial and architectural contexts:

Industrial Applications

- Catwalks and elevated walkways

- Oil and gas facilities

- Mining platforms

- Power plants

- Construction scaffolding

- Stair treads and ramps

Architectural Applications

- Decorative building facades

- Ceiling panels

- Balconies and terraces

- Sunshades and fences

- Ventilation covers

Companies like Huijin Metal Mesh demonstrate the material’s adaptability, supplying aluminum grating that performs equally well in functional and decorative roles.

How Does Aluminum Safety Grating Compare to Steel?

While steel grating has traditionally dominated industrial flooring, aluminum safety grating offers several advantages:

- Weight – aluminum is one-third the weight of steel, easing installation.

- Corrosion resistance – aluminum forms a natural oxide layer, reducing the need for coatings.

- Maintenance – requires less upkeep than steel in humid or corrosive environments.

- Cost – while initially more expensive, aluminum lowers long-term costs by reducing replacement frequency.

- Aesthetics – aluminum’s modern finish suits architectural applications better than steel.

What Standards Govern Aluminum Safety Grating?

Safety and performance are regulated by several international standards:

- OSHA (Occupational Safety and Health Administration, U.S.) – establishes slip resistance and load-bearing requirements.

- EN 1991 (Eurocode) – European standard for structural safety.

- ASTM Standards – define materials, dimensions, and manufacturing tolerances.

- ISO Certification – ensures quality management and production consistency.

Compliance with these standards guarantees that aluminum safety grating meets safety and reliability benchmarks across industries.

How to Select the Right Aluminum Safety Grating?

Selecting the correct type depends on several factors:

- Load Requirements – pedestrian-only vs. machinery loads.

- Environmental Conditions – dry indoor use vs. wet or corrosive outdoor use.

- Slip Resistance – higher traction required in icy or oily areas.

- Drainage Needs – perforated or open-bar designs for liquid-heavy settings.

- Aesthetic Considerations – architectural designs may prioritize appearance over load-bearing capacity.

How Is Aluminum Safety Grating Installed?

Installation typically involves:

- Measurement and Cutting – panels are cut to fit the designated area.

- Framing and Support – gratings are secured to a support structure.

- Fastening – using clips, bolts, or welding depending on design.

- Inspection – ensuring panels are level, secure, and compliant with safety codes.

Proper installation ensures maximum durability and worker safety.

What Are the Maintenance Practices for Aluminum Safety Grating?

Although aluminum safety grating is low-maintenance, regular care extends its lifespan:

- Cleaning – removing dirt, oil, or snow buildup.

- Inspection – checking for loose fasteners or structural wear.

- Replacement – damaged panels should be replaced immediately to maintain safety.

What Are the Future Trends of Aluminum Safety Grating?

The market is evolving toward:

- Eco-friendly alloys – focusing on recyclability and reduced carbon footprint.

- Hybrid materials – combining aluminum with coatings for enhanced durability.

- Aesthetic innovation – more customized patterns for architectural design.

- Automation in manufacturing – precision production reduces waste and ensures higher consistency.

Conclusion

Aluminum safety grating is a versatile, durable, and safe solution for industries and architecture alike. Its wide range of types, including diamond grip, O-grip, traction tread, bar, swage-locked, riveted, and serrated designs, ensures there is an option for every application. Compared with steel, it is lighter, more corrosion-resistant, and often more cost-effective in the long run. By understanding the different varieties and their specific benefits, users can select the most appropriate aluminum safety grating for their projects, ensuring safety, efficiency, and long-term performance.

Comments