Introduction to CO2 Liquefaction

CO2 liquefaction is a critical process in carbon capture, storage, and utilization, transforming gaseous carbon dioxide into a liquid form for easier transport and use. Industries such as food and beverage, chemical manufacturing, and carbon capture and storage (CCS) rely on CO2 liquefaction plants to meet operational needs. The process involves cooling and compressing CO2 to its liquid state, typically at temperatures below -56°C and pressures above 5.1 atmospheres. This article explores the costs of establishing and operating a CO2 liquefaction plant, offering insights into the factors that drive expenses.

Why CO2 Liquefaction Matters

CO2 liquefaction plants play a pivotal role in reducing carbon emissions by enabling the capture and repurposing of CO2 from industrial processes. Applications include beverage carbonation, food preservation, and enhanced oil recovery. The demand for liquid CO2 is growing, with the global market projected to reach $2,071.22 million by 2028, driven by a compound annual growth rate of 4.82% from 2023 to 2030. Understanding the costs of CO2 liquefaction is essential for businesses planning to invest in this technology.

Factors Influencing CO2 Liquefaction Plant Costs

The cost of a CO2 liquefaction plant varies widely based on several factors, including plant capacity, technology, location, and energy requirements. Below, we break down the key components affecting the overall cost.

Capital Investment (CapEx)

The capital expenditure for a CO2 liquefaction plant includes equipment, engineering, and installation costs. According to industry data, the capital cost for a large-scale CO2 liquefaction plant can range from $10 million to $50 million, depending on capacity and complexity. For smaller plants, such as those producing 100–500 tons per day (TPD), costs typically fall between $5 million and $15 million.

- Equipment Costs: Major components include compressors, heat exchangers, and refrigeration systems. For instance, a CO2 compressor and ammonia-based refrigeration circuit are critical for liquefaction. Companies like Hangzhou Z-Oxygen Intelligent Device Co., Ltd. provide advanced solutions for such systems.

- Engineering and Design: Customized designs for specific feed gas compositions or applications, such as integration with an Airgas Microbulk Tank for LO2 LN2 LAr LNG and LCO2, can increase costs due to specialized engineering.

- Installation and Infrastructure: Site preparation, piping, and storage tanks add to the initial investment. Modular plants, which offer pre-tested components, can reduce installation costs by up to 20%.

Operational Costs (OpEx)

Operational expenses for CO2 liquefaction plants include energy, maintenance, and labor costs. These are ongoing costs that significantly impact the economic viability of a plant.

- Energy Consumption: CO2 liquefaction is energy-intensive, requiring approximately 100 kWh per ton of CO2 liquefied, translating to a cost of $10–$20 per ton at average electricity rates of $0.10–$0.20 per kWh. Energy-efficient designs, such as those using advanced cryogenic systems, can lower these costs.

- Maintenance: Regular maintenance of compressors, dryers, and adsorbers ensures operational efficiency. Annual maintenance costs typically range from 2–5% of the initial capital investment.

- Labor: Operating a CO2 liquefaction plant requires skilled technicians and operators. Labor costs vary by region but can account for 10–20% of operational expenses.

Feedstock and Raw Material Costs

The cost of sourcing CO2 is a significant factor. CO2 is often a byproduct of industrial processes like ammonia production or ethanol fermentation. For example, ethanol plants produce high-purity CO2, reducing purification costs to $15–$25 per ton. In contrast, capturing CO2 from dilute sources like cement production can cost $40–$120 per ton due to additional processing.

Location and Regulatory Factors

Geographic location affects both capital and operational costs. In regions with high energy prices, such as Europe, operational costs may be higher. Conversely, areas with abundant natural gas, like the U.S., benefit from lower feedstock costs. Regulatory requirements, such as environmental permits or carbon taxes, can also increase expenses, particularly in regions like Germany, where CO2 prices reached $221 per ton in Q1 2025.

CO2 Liquefaction Process and Technology

Understanding the CO2 liquefaction process is key to evaluating its costs. The process typically involves compression, cooling, and purification, with variations based on the desired purity and application.

How CO2 Liquefaction Works

The CO2 liquefaction process begins with capturing gaseous CO2 from industrial sources. The gas is compressed to increase its pressure, cooled to remove water and impurities, and then liquefied using a refrigeration cycle, often with ammonia as the refrigerant. The liquefied CO2 is stored in pressurized tanks, such as the Airgas Microbulk Tank for LO2 LN2 LAr LNG and LCO2, for distribution to industries like food and beverage or welding.

Technological Innovations

Recent advancements have reduced CO2 liquefaction plant costs. For example:

- Modular Designs: Standardized, modular plants reduce engineering and installation costs while maintaining flexibility for varying feed gas compositions.

- Energy Optimization: Integrating CO2 liquefaction with renewable energy sources or waste heat recovery systems can lower energy costs by 10–15%.

- Alternative Technologies: Membrane-based separation is emerging as a lower-cost alternative to cryogenic methods, though it is less common for high-purity applications.

Cost Estimates for CO2 Liquefaction Plants in 2025

Based on recent data, the cost of CO2 liquefaction plants in 2025 varies by scale and application. Below are estimated cost ranges:

- Small-Scale Plants (100–500 TPD): Capital costs range from $5 million to $15 million, with operational costs of $20–$40 per ton of CO2. These plants are suitable for localized applications like beverage carbonation.

- Medium-Scale Plants (500–2,000 TPD): Capital costs range from $15 million to $30 million, with operational costs of $15–$30 per ton. These are common in industrial hubs with access to CO2-rich feedstocks.

- Large-Scale Plants (>2,000 TPD): Capital costs can exceed $50 million, with operational costs as low as $10–$20 per ton due to economies of scale. These plants are often integrated with CCS projects.

Price Trends for Liquid CO2

In Q1 2025, liquid CO2 prices in the U.S. reached $783 per ton, driven by high natural gas prices and demand from the food and beverage sector. In contrast, prices in India were lower at $330 per ton, reflecting regional differences in energy and feedstock costs. These price trends impact the economic feasibility of CO2 liquefaction plants, as higher market prices can offset operational costs.

Economic Viability and ROI Considerations

The economic viability of a CO2 liquefaction plant depends on balancing capital and operational costs with revenue from CO2 sales. For instance, a plant producing 500 TPD with a capital cost of $15 million and operational costs of $20 per ton can achieve a return on investment (ROI) of 10–20% annually, assuming a selling price of $100–$200 per ton. Factors like government incentives for carbon capture or proximity to CO2-consuming industries can further enhance ROI.

Strategies to Reduce Costs

To improve the economics of CO2 liquefaction plants, consider the following strategies:

- Leverage Byproduct CO2: Sourcing CO2 from high-purity streams, such as ethanol plants, reduces purification costs.

- Adopt Modular Systems: Modular plants lower upfront costs and accelerate deployment.

- Integrate Renewables: Using renewable energy for compression and cooling can reduce operational expenses.

- Optimize Scale: Larger plants benefit from economies of scale, reducing per-ton costs.

Applications of Liquid CO2

Liquid CO2 has diverse applications, driving demand for CO2 liquefaction plants:

- Food and Beverage: Used for carbonation and food preservation, accounting for over 50% of global demand.

- Industrial Uses: Employed in welding, chemical synthesis, and enhanced oil recovery.

- Healthcare: Used in cryotherapy and pharmaceutical extraction processes.

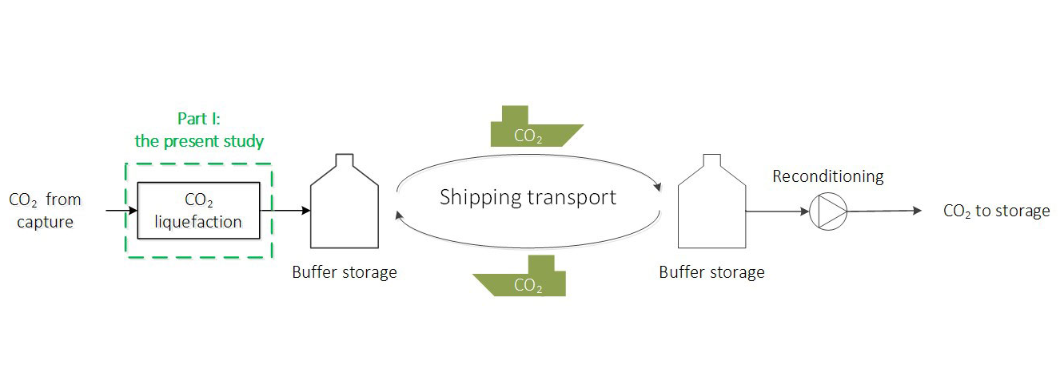

- Carbon Capture and Storage: Liquefied CO2 is transported and stored to reduce greenhouse gas emissions.

Challenges and Future Outlook

Despite its benefits, CO2 liquefaction faces challenges, including high energy costs and supply chain disruptions. In Q1 2025, logistical issues in Europe and tariff uncertainties in the U.S. impacted CO2 prices and availability. However, ongoing innovations, such as improved refrigeration cycles and integration with renewable energy, are expected to lower costs and enhance adoption. By 2030, advancements in direct air capture and CO2 utilization could further transform the economics of CO2 liquefaction plants.

Conclusion

The cost of a CO2 liquefaction plant depends on factors like capacity, technology, and location, with capital costs ranging from $5 million to over $50 million and operational costs of $10–$40 per ton. By leveraging high-purity CO2 sources, modular designs, and energy-efficient technologies, businesses can optimize costs and improve ROI. As demand for liquid CO2 grows in industries like food, beverage, and CCS, understanding these costs is crucial for stakeholders aiming to invest in sustainable solutions.

Comments