In today’s fast-paced manufacturing and packaging industries, businesses continually seek innovative solutions to improve efficiency, reduce waste, and enhance product presentation. One such solution that has revolutionized the packaging process is the shrink film heat tunnel. This technology, though seemingly simple, offers a range of substantial benefits that streamline production processes and ensure consistent packaging quality. Let’s explore how shrink film heat tunnels are transforming modern production lines and why they’re a vital investment for businesses aiming to stay competitive.

Understanding the Shrink Film Heat Tunnel

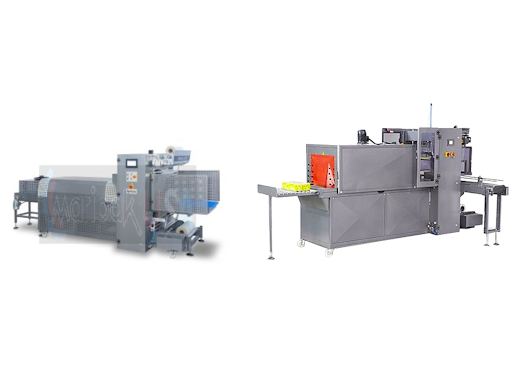

A shrink film heat tunnel is a specialized piece of equipment designed to apply controlled heat to shrink film material wrapped around products. As products move through the tunnel, the heat causes the shrink film to contract tightly around the item, resulting in a secure, tamper-evident, and professional-looking package. These tunnels come in various sizes and configurations to accommodate different product dimensions and production requirements.

Unlike traditional packaging methods, shrink film heat tunnels provide uniform heating, ensuring that each package emerges with consistent quality. This uniformity is critical, especially in industries where product presentation and integrity directly influence customer satisfaction and brand reputation.

How Shrink Film Machines Enhance Efficiency

Integrating shrink film machines into a production line brings numerous advantages. These machines automate the wrapping process, reducing the need for manual labor and minimizing the risk of human error. Automation not only accelerates production rates but also maintains consistent packaging standards, which is crucial for maintaining brand image and customer trust.

Moreover, shrink film machines are designed to handle a wide variety of products, from food items and cosmetics to electronics and pharmaceuticals. Their versatility makes them an ideal solution for businesses with diverse product ranges. The ability to quickly adapt to different product shapes and sizes without significant downtime further enhances operational efficiency.

Key Benefits of Shrink Film Heat Tunnels for Production Lines

1. Improved Packaging Quality

One of the standout benefits of shrink film heat tunnels is the superior packaging quality they provide. By applying consistent heat across the entire surface of the shrink film, these tunnels eliminate unsightly wrinkles, air pockets, and uneven shrinkage. The result is a smooth, professional-looking package that enhances the perceived value of the product.

2. Enhanced Protection and Security

Shrink film creates a protective layer that shields products from dust, moisture, and other environmental factors. The tight, tamper-evident seal also deters theft and ensures product integrity during transportation and storage. For industries like food and pharmaceuticals, where product safety is paramount, this added layer of protection is indispensable.

3. Increased Throughput

By streamlining the packaging process, shrink film heat tunnels significantly boost production throughput. Manual wrapping processes can be time-consuming and labor-intensive, leading to bottlenecks in the production line. With automated shrink film systems, products move through the tunnel swiftly, allowing businesses to meet higher demand levels without compromising on quality.

4. Cost Savings

While the initial investment in a shrink film heat tunnel may seem substantial, the long-term savings are considerable. Reduced labor costs, minimal material waste, and decreased product damage contribute to a more cost-effective operation. Additionally, the efficient use of energy in modern heat tunnels reduces utility expenses, further enhancing the return on investment.

5. Environmental Benefits

Sustainability is a growing concern for many businesses, and shrink film heat tunnels can contribute to greener operations. Shrink film materials are often recyclable, and the precise application of heat reduces excess material use. Some modern tunnels are designed to operate at lower temperatures and with energy-saving features, aligning with corporate sustainability goals.

6. Versatility and Customization

Shrink film heat tunnels can be customized to meet specific production needs. Adjustable temperature controls, conveyor speeds, and tunnel sizes enable businesses to fine-tune the packaging process for different products. This flexibility is especially beneficial for companies that package multiple product types, as it minimizes the need for additional equipment and reduces setup times.

7. Space Optimization

Space constraints are a common challenge in many production facilities. Shrink film heat tunnels are compact and can be integrated seamlessly into existing lines without requiring significant floor space. This efficient use of space allows businesses to maximize productivity without extensive facility modifications.

Future-Proofing Your Production Line

As consumer expectations continue to rise and industries evolve, investing in advanced packaging solutions like shrink film heat tunnels becomes increasingly crucial. These systems not only enhance production efficiency but also provide the adaptability needed to keep pace with changing market demands. Whether you’re in food processing, electronics, retail, or pharmaceuticals, integrating a shrink film heat tunnel into your production line positions your business for long-term success.

Conclusion

The shrink film heat tunnel stands out as a vital component for businesses seeking to streamline their production processes. Its ability to deliver consistent packaging quality, increase throughput, reduce costs, and support sustainability initiatives makes it an invaluable asset across diverse industries. When combined with shrink film machines, businesses can achieve a seamless, efficient, and reliable packaging operation. By adopting this technology, companies not only enhance operational performance but also strengthen their competitive edge in an increasingly demanding market.

Comments