Strip brushes are so diverse in their utility, providing helpful applications across a multitude of industries. From sealing to cleaning and guiding and protection, strip brushes are critical components in any application requiring precision, durability, and adaptability for industry, commerce, or private residences. Are you someone who wants to gather more facts about the strip brushes? If Yes. This is the best place where people can gather more facts about the strip brushes.

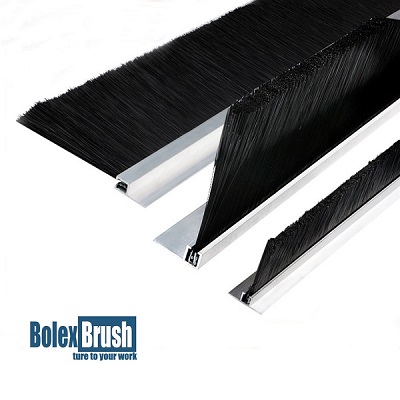

The Durable Strip Brushes

Most commonly used applications of strip brushes include sealing. They can be installed in residential or industrial environments in order to block the entry of dust, water, air, and even insects. As they are mounted in the doors, windows, or other machinery of an industrial nature, the flexible bristles accommodate uneven surfaces to provide a more efficient seal while reducing energy loss and protecting fragile components. This sealing capability is also particularly advantageous in a number of industries where maintaining controlled environments is critical-in food processing or, for that matter, electronics manufacturing.

Another major area where strip brushes are very good is in cleaning. Conveyor belts, rollers, and other industrial surfaces tend to gather debris that can slow down operations or cause wear and tear. Strip brushes are meant to remove dirt and particles efficiently, thus allowing smooth operation and reducing downtime. Their robust bristles can handle demanding cleaning tasks without damaging surfaces, thus being perfect for industries like mining, manufacturing, and packaging.

In assembly lines and automated systems, strip brushes can guide and locate products. They can be soft yet firm in texture, providing gentle holding against surfaces, which keeps them in position and orientation without creating unwanted errors. It makes all the difference between automotive and electronics manufacturing.

Strips are also protector devices on delicate surfaces and materials. The device works as an edge guard or a bumper that guards against marks, dents, or other forms of damage either during production or transportation. This makes them invaluable in sectors where materials like glass, metal, or polished surfaces must remain pristine.

Another niche application for strip brushes is in static control. Build-up of static electricity may cause significant problems, particularly in industries dealing with sensitive electronic components. Conductive bristle strip brushes help dissipate static charges and provide a safe working environment while protecting delicate equipment.

What makes strip brushes different is their durability and low-maintenance nature. Made from durable materials, these brushes are designed to withstand the most demanding conditions and can be used for a long time even in harsh environments. Tailoring strip brushes to exact requirements ensures optimum performance in any application.

Strip brushes also prove environmentally friendly. Most are produced in recyclable materials. This adds to their reasonability when considering waste control as part of a company's operational reductions. Serving a duration before needing to be replaced enhances their environmentally friendly properties because fewer units are needed in a similar time span.

Strip Brushes are necessary equipment with flexibility, durability, and affordability. Such functions are sealed, cleaned, guided, protected, and static controlled. Such makes strip brushes a need for any industry. They may be used to safeguard sensitive materials or ensure smooth operation of machinery. Strip brushes serve as a practical solution for optimizing efficiency and protection. Making an investment in high-quality, tailored strip brushes is a savvy decision that provides both short and long-term advantages.

Author’s Bio:

Now, its time for people to uncover top benefits of the Strip Brushes for the best experience.

Comments