Vacuum chambers are essential tools in various industries, from manufacturing to research, offering precise control over atmospheric conditions for a range of processes. One key component that ensures these chambers function optimally is the Vacuum Service Valves. These valves regulate the flow of gases into and out of the chamber, maintaining the desired pressure and preventing contamination. In this article, we’ll explore the importance of these valves, how vacuum chambers work, and the role of companies like GNB KL Group in the industry.

What is a Vacuum Chamber?

A vacuum chamber is a sealed enclosure in which air and other gases are removed to create a low-pressure environment. These chambers are used for processes that require the absence of air or a controlled environment, such as in electronics manufacturing, space simulations, and scientific research. The absence of air prevents contamination and allows for precise manipulation of materials under specific atmospheric conditions.

Vacuum Service Valves play a pivotal role in the operation of vacuum chambers. They are responsible for controlling the flow of air and gases, either by allowing them to enter or exit the chamber or by sealing the chamber to maintain a vacuum. Without these valves, it would be nearly impossible to control the atmospheric pressure inside the chamber accurately.

The Role of Vacuum Chambers in Various Industries

Vacuum chambers are used across a broad spectrum of industries. Here are a few key applications:

Semiconductor Manufacturing: In the production of semiconductors, even the smallest particle can ruin an entire batch. Vacuum chambers provide a controlled, particle-free environment that is crucial for the precision required in these processes.

Aerospace Testing: Before equipment can be sent into space, it must undergo rigorous testing. Vacuum chambers simulate the conditions of outer space, including the absence of atmosphere and extreme temperatures, ensuring that equipment can withstand such conditions.

Pharmaceuticals: Many pharmaceutical products are sensitive to air and moisture. Vacuum chambers are used to dry and preserve these products without exposing them to contaminants that could compromise their quality.

Material Science: Researchers use vacuum chambers to study the behavior of materials in a controlled environment, often at very low pressures. This is essential for understanding how materials react to different environmental conditions.

Importance of Vacuum Service Valves

As mentioned earlier, Vacuum Service Valves are crucial in maintaining the functionality of vacuum chambers. Their importance cannot be overstated, as they regulate the environment within the chamber, making it possible to carry out precise operations. These valves are typically robust and made from materials that can withstand the extreme conditions within a vacuum chamber, such as stainless steel or other corrosion-resistant metals.

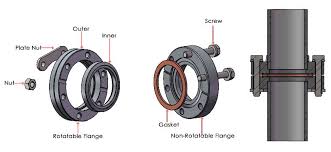

There are several types of vacuum service valves used in vacuum systems:

Isolation Valves: These valves are used to isolate certain parts of the vacuum system, either to allow for maintenance or to protect sensitive components from exposure to atmospheric pressure.

Control Valves: These valves modulate the flow of gases into and out of the vacuum chamber, ensuring that the correct pressure is maintained.

Relief Valves: These are safety valves that release pressure if it exceeds a certain threshold, protecting the vacuum chamber from damage.

Each type of valve plays a critical role in the smooth operation of a vacuum chamber, and their quality and reliability are paramount.

The Role of GNB KL Group in Vacuum Technology

GNB KL Group is a leader in the vacuum technology industry, providing high-quality vacuum products and services, including vacuum chambers, valves, and other essential components. With years of experience and a commitment to innovation, they have become a trusted name in industries that rely on vacuum technology.

The company offers a range of products designed to meet the specific needs of its clients, whether in research, manufacturing, or any other field that requires precise control of atmospheric conditions. Their expertise in Vacuum Service Valves ensures that these critical components are durable, efficient, and capable of withstanding the rigors of industrial use.

Selecting the Right Vacuum Chamber and Components

When choosing a vacuum chamber, several factors should be considered:

Size and Shape: The size and shape of the vacuum chamber should match the requirements of the process for which it will be used. A chamber that is too small may not be able to accommodate the necessary equipment, while one that is too large could be inefficient in terms of energy consumption and maintenance.

Material: The material of the chamber and its components, such as valves, should be chosen based on the operating conditions. For example, a stainless steel chamber may be ideal for processes that involve corrosive materials, while an aluminum chamber may be better suited for applications where weight is a concern.

Pressure Requirements: Different processes require different levels of vacuum. It’s important to select a chamber and valves that can achieve and maintain the desired pressure without compromising performance.

Cost vs. Durability: High-quality vacuum chambers and components, like those from GNB KL Group, may come with a higher initial cost, but they often provide better long-term value due to their durability and reliability. Cheaper options may result in frequent maintenance and replacement, leading to higher overall costs.

Conclusion

Vacuum chambers are an indispensable part of many industries, enabling processes that require precise control of atmospheric conditions. At the heart of these systems are Vacuum Service Valves, which play a crucial role in maintaining the environment inside the chamber. Companies like GNB KL Group provide high-quality products and services that ensure the reliable and efficient operation of vacuum systems.

By understanding the role of vacuum chambers and their components, industries can make informed decisions that lead to better outcomes, whether in manufacturing, research, or testing. As technology advances, the role of vacuum systems will only grow, making it more important than ever to choose the right equipment for your needs.

Comments