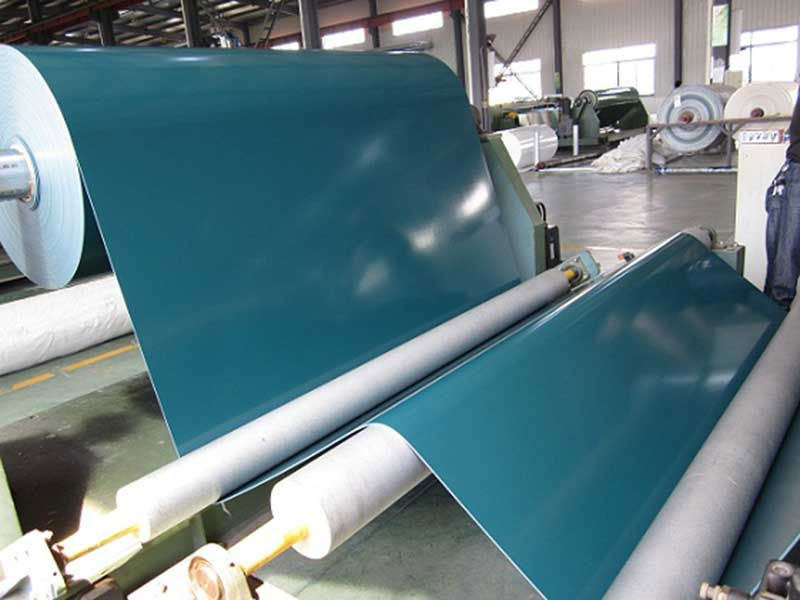

PU conveyor belts are a new generation concept offering a wide range of conveyor belts capable of enduring heavy loads while being flexible and easy to install. These belts are manufactured from polyurethane (PU) and can easily withstand the various conditions found in industrial uses. They are especially used in industries where reliability and production are of high value. There are several benefits of using PU Conveyor for conveying products including the following -

1. Durability and Longevity

Several notable characteristics of Powertwist conveyor belts are worthy of mention here, but the most prominent one is the fact that these belts are extremely durable. Compared to traditional rubber or PVC belts PU belts are much more durable and can withstand chemical, wear and tear and extreme temperature changes. This has a long term implication of longer product longevity and reduced service costs for industrial uses of such structures.

2. Flexibility and Customization

Features of belts are very flexible in nature, and that is why they can easily negotiate any type of conveyors. This flexibility is accompanied by the capacity that enables the manufacturer to adjust the belt to certain dimensions without any need for tools, or even welding. These belts are in fact designed in modular fashion and this makes it easy to assemble by then adjust to enable productivity to be as high as possible with very little time being spent on belts.

3. Enhanced Performance

These belts have a unique ability to perform when they are used. These shoes offer great grip and are able to support heavy loads while offering comparatively low slipping or skidding. The PU material also exhibit excellent resistance to oils, fats, and other substances and thus these belts are perfect for food processing industries and other related fields which require high standards of cleanliness.

Use of Powertwist PU conveyor Belts

PU conveyor belt are very functional and can be used to suit numerous requirements. Some of the key sectors that benefit from these belts include:

Food and Beverage Industry: They are resistant to oils and chemicals, and therefore are ideal for use in food processing and packaging industries.

Automotive Industry: One of the most important characteristics of structural metals is their strength and ability to carry heavy loads, which makes them perfect for automotive production.

Pharmaceutical Industry: Due to their high hygiene and ability to defend against contaminants they are suitable for pharmaceutical applications.

Material Handling: They are generally useful for most types of material handling in warehouses and distribution facilities, because of their versatility and durability.

Installation and Maintenance

Powertwist PU belts are easily integrated into any operation as they feature a modular design. They can be readily disconnected and connected, which makes one to be capable of making changes and replacement with ease. These features make installation easy and therefore minimize the time taken and increase operational capacity. It requires less maintenance where checks, washing, and other forms of maintenance are done to ensure the machines are running efficiently.

Conclusion

The PU belt is a new and improved version in conveyor technology. This makes them suitable for numerous uses in the industrial applications given that they endure the tests of time, flexibility and high performance. The adoption of belts in a business will help realize high efficiency since the belts will be more efficient and eventually require less maintenance which will increase productivity.

For those intending to adopt these qualities conveyor belts in their systems, Powell PU conveyor belts known as conveyor belts are available from Lakhotia Conveyors Pvt Ltd in a wide variety. For all the conveyor belt needs, then Lakhotia Conveyors Pvt Ltd is the supplier that you can trust due to its quality and satisfied customers.

Comments