Efficient piping systems are critical for the smooth functioning of various industries, including oil and gas, chemical processing, water treatment, and more. One essential component that ensures optimized flow and prevents performance issues is the eccentric reducer. This article covers what is an eccentric reducer, its benefits, and what is the application of eccentric reducer in modern piping systems.

What is an Eccentric Reducer?

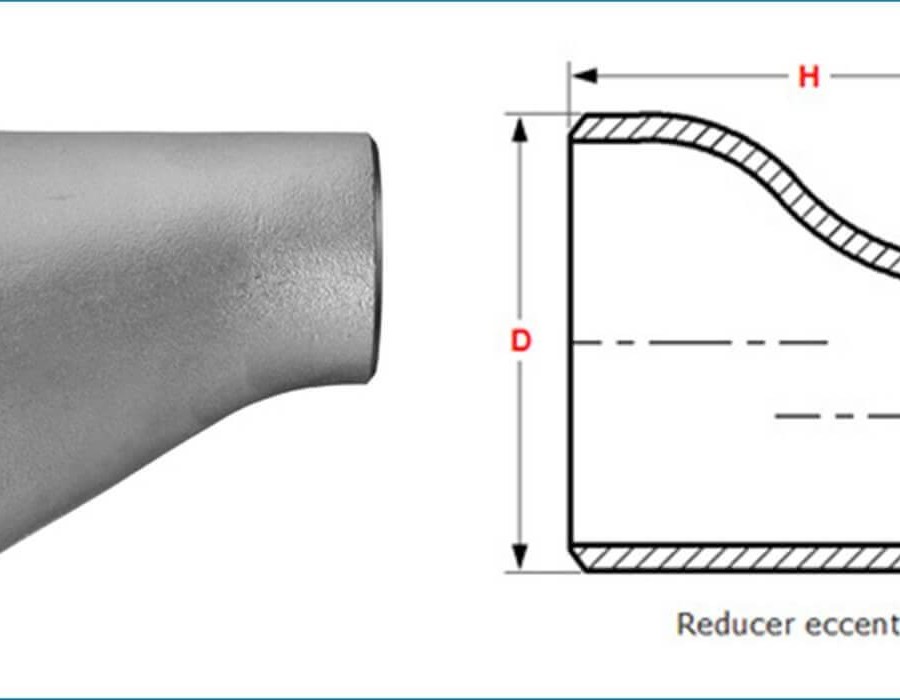

An Eccentric Reducer is a type of pipe fitting used in piping systems to connect two pipes of different diameters. Unlike a concentric reducer, which has a symmetrical shape, an eccentric reducer has one side that is flat, allowing for an offset connection between the two pipes.

Its unique design prevents air pockets in fluid flow and ensures seamless transfer of liquids or gases, especially in horizontal piping systems. By maintaining proper alignment, it minimizes disruptions and helps avoid flow-related inefficiencies.

Key Characteristics of Eccentric Reducers:

- Flat Design on One Side: Prevents accumulation of air or gas at the top of horizontal pipes.

- Wide Range of Materials: Eccentric reducers are available in materials like stainless steel, carbon steel, and alloys to suit different applications.

- Variety of Sizes: They come in diverse sizes to match varying industrial requirements.

Top Benefits of Eccentric Reducers

Eccentric reducers play a vital role in ensuring steady and efficient flow across piping systems. Here are their key benefits:

1. Prevention of Air Accumulation

One of the primary advantages of Eccentric Reducers is their ability to prevent air pocket formation. The flat side of the reducer aligns with the bottom (or top, depending on orientation), ensuring that air or vapor does not get trapped within the pipe. This feature is especially important in horizontal pipelines where uninterrupted flow is essential.

2. Improved Flow Dynamics

By reducing the diameter of the pipe while maintaining proper alignment, Eccentric Reducers help reduce fluid turbulence. This results in a smoother flow, minimizing pressure drops and ensuring more efficient operation across the system.

3. Flexible Installation

Eccentric reducers can be installed with the flat side either upward or downward, based on system requirements. For example:

- Flat side up: Used to prevent air entrapment in liquid flow.

- Flat side down: Used to avoid the buildup of sediments or solids at the pipe’s bottom.

4. Space-Saving Solution

Compared to other pipe fittings, eccentric reducers take up less space, making them ideal for compact or constrained installations. This is particularly useful in industries like HVAC or power plants, where pipeline layouts can be highly complex.

5. Versatile Material Options

Eccentric reducers are manufactured in various materials to suit diverse industrial needs. For example:

- Stainless steel reducers are preferred for corrosive environments, such as chemical plants.

- Carbon steel reducers are commonly used in oil and gas applications due to their strength and durability.

6. Enhanced System Safety

By preventing flow interruptions, turbulence, and reduction in pressure build-up, eccentric reducers contribute to the overall safe operation of a piping system. This reduces the risk of damage to other equipment or failures in critical setups.

What is the Application of Eccentric Reducer?

Eccentric reducers are extensively used in a wide range of industries. Here’s what is the application of eccentric reducer and where their role becomes indispensable:

1. Oil and Gas Pipelines

Eccentric Reducers are crucial in oil pipelines to ensure the smooth flow of crude oil and prevent air from getting trapped. They are equally important in gas pipelines where proper alignment avoids pressure drops and ensures uninterrupted supply.

2. Chemical Processing

Industries working with corrosive liquids and gases rely on eccentric reducers to maintain system integrity and efficiency. Their ability to mitigate turbulence is critical in pipelines carrying reactive chemicals.

3. Power Generation

Power plants use eccentric reducers in systems like cooling water pipelines and steam lines to eliminate air pockets or sediment buildup, ensuring that equipment operates without obstructions.

4. HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems require an even distribution of fluids and air for efficient performance. Eccentric Reducers optimize piping layouts while ensuring a steady flow to achieve uniform heating or cooling.

5. Water Treatment

Eccentric Reducers play a vital role in water treatment facilities. They prevent sediment deposits in pipes used for wastewater and clean water transfer, ensuring smoother operations and reducing maintenance needs.

6. Food and Beverage Industry

Used in sanitary pipelines, eccentric reducers ensure hygienic and uninterrupted flow of liquids like milk, juices, or syrups. Stainless steel variants are particularly preferred here for their corrosion resistance and easy cleaning.

Eccentric Reducers’ specific design allows them to cater to industries with unique flow and pressure requirements. Their versatility and adaptability make them indispensable in modern piping setups.

Final Thoughts

Eccentric Reducers are a vital component of any well-functioning piping system. With their ability to optimize flow, prevent air accumulation, and reduce turbulence, they ensure the safe and efficient transportation of fluids and gases. Neo Impex Stainless Pvt. Ltd. provides high-quality eccentric reducers designed to meet diverse industrial needs. By understanding what is an eccentric reducer and what is the application of eccentric reducer, you can make better decisions when designing or maintaining industrial pipelines.

Comments