Australian Valve is the greatest Lubricated Plug Valve Manufacturer in Australia. We supply to cities like Geelong, Brisbane and Wollongong. Lubricated plug valves are industrial valves that are designed to control the flow of liquids, gases, and other media in pipeline systems. The valve is comprised of a cylindrical plug that rotates within a body to either allow or restrict flow. The plug features one or more ports to direct the flow of media, and its shape can vary depending on the type of media being controlled.

Lubricated plug valves are known for their durability and reliable performance, as well as their ability to handle high-pressure and high-temperature applications. The valve's internal components are lubricated to reduce friction and wear, ensuring smooth operation and extending the valve's lifespan. There are several different types of lubricated plug valves, including full-bore, reduced-bore, and multi-port. Each type offers unique benefits and is suited to different applications, making it important to choose the right valve for your specific needs. When selecting a lubricated plug valve, it's important to consider factors such as pressure and temperature ratings, material compatibility, and flow rate requirements. You should also consider the type of media being controlled, as well as the size and type of pipeline system you are working with.

Australian Valve is well known Lubricated Plug Valve Manufacturer in Australia and provides durability, reliability, and versatility, they are an excellent choice for a wide range of applications.

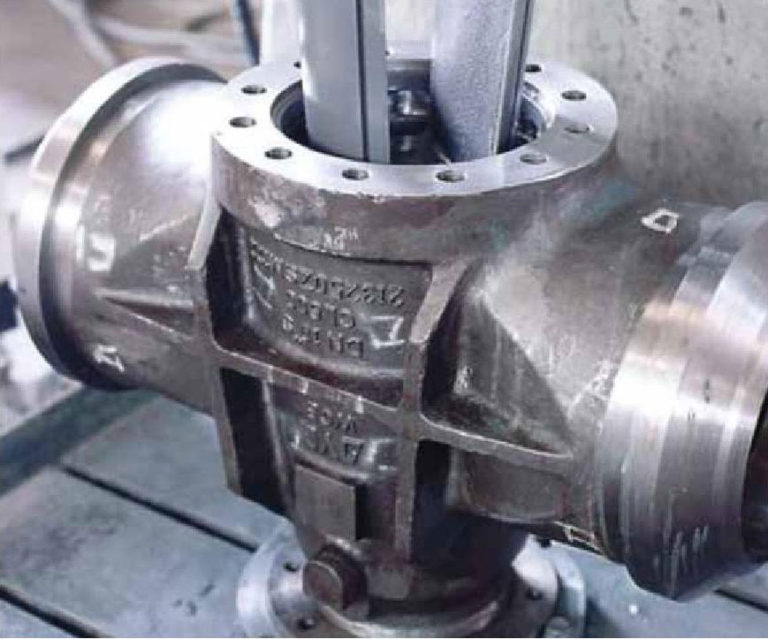

Parts of Lubricated Plug Valve:

· Body

· Plug

· Sealing surface

· Gland

· Handle

· stem

Advantages of Lubricated Plug Valve:

1. Tight Shut-off: Lubricated plug valves are designed to provide a tight shut-off, meaning that they can completely block the flow of the fluid passing through them. This feature makes them ideal for applications where leakage cannot be tolerated.

2. Easy Operation: Lubricated plug valves are relatively easy to operate, requiring only a quarter-turn of the valve handle to open or close the valve. This makes them a popular choice in applications where frequent on/off cycling is required.

3. Low Friction: The lubrication used in lubricated plug valves reduces friction between the valve plug and the valve body, allowing for smooth and efficient operation.

4. Durability: Lubricated plug valves are designed for long-term durability and reliability, making them an ideal choice for applications that require high cycle life and low maintenance.

Applications of Lubricated Plug Valve:

- Oil and Gas: Lubricated plug valves are commonly used in the oil and gas industry for pipeline applications, such as pipeline pigging, flow diversion, and crude oil gathering.

- Chemicals: Lubricated plug valves are suitable for handling a variety of chemicals, including corrosive and hazardous chemicals. They are commonly used in chemical plants for handling acids, alkalis, and other chemicals.

- Water and Wastewater: Lubricated plug valves are commonly used in water treatment plants for controlling the flow of water and wastewater.

- Power Generation: Lubricated plug valves are used in power plants for controlling the flow of steam and other fluids.

Industries:

1.Oil & Gas

2. Corrosive Substance processing

3.Power Generation

4.Chemical

5.Production

Description

Body materials: Carbon steel, cast steel (WCB, WCC, WC9, WC6, LCC, LCB) Cast iron, ductile iron, SS304, SS316, CF8.

Class: 150-2500. PN16 – PN450.

Size: ½” to 24”.

Ends: Socket weld, buttweld, flanged, threaded.

Operations: Lever operated,Gear operated, Pneumatic Actuated, Electric Actuated.

Visit our website- https://www.australianvalve.com/product-category/lubricated-plug-valve/

Comments