In modern industries, laboratories, data centers, and electronic manufacturing units, even the smallest static discharge can cause damage or disruption. To counter this, conductive rubber tiles have become a reliable flooring choice, combining safety, durability, and functionality in one solution.

This article explores what conductive rubber tiles are, their benefits, applications, and why they are essential in static-sensitive environments.

🧩 What Are Conductive Rubber Tiles?

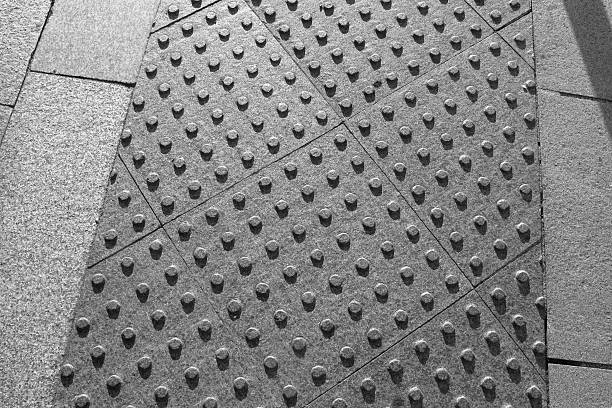

Conductive rubber tiles are specialized flooring materials designed to dissipate static electricity safely to the ground. They are made using a blend of natural and synthetic rubbers combined with carbon or other conductive materials that create an electrical pathway through the floor.

This helps prevent the build-up of electrostatic discharge (ESD), which can otherwise damage sensitive equipment, cause data loss, or even ignite flammable substances in certain industrial environments.

⚙️ How Do They Work?

Conductive rubber tiles contain carbon granules or fibers that form a conductive network throughout the material. When installed over a properly grounded subfloor, static charges on personnel, tools, or machines are safely transferred to the earth.

This makes them ideal for ESD-protected areas (EPAs) where controlling static electricity is a key safety requirement.

🏭 Key Benefits of Conductive Rubber Tiles

🔋 1. Static Control and Safety

The primary function of conductive rubber tiles is to minimize static discharge. This ensures the protection of both workers and sensitive electronic devices. Industries such as semiconductors, aerospace, and healthcare rely on this flooring to maintain safe operational conditions.

🧱 2. Durability and Strength

Unlike standard vinyl or PVC flooring, rubber tiles are resilient and long-lasting. They can withstand heavy machinery, rolling loads, and continuous foot traffic without cracking or peeling. Their natural elasticity also provides excellent impact absorption.

🌍 3. Environmentally Friendly Option

Many conductive rubber tiles are manufactured from recycled or sustainable rubber sources, making them an eco-friendly choice. They also contribute to improved indoor air quality by being low-VOC (volatile organic compounds) and free from harmful plasticizers.

🧼 4. Easy Maintenance

Rubber tiles require minimal maintenance. Regular sweeping and occasional damp mopping are enough to keep them looking new. Their seamless surface resists dirt accumulation, ensuring a clean and professional appearance in workspaces.

👣 5. Comfort and Noise Reduction

Because rubber is naturally cushioned, these tiles provide a comfortable surface to stand or walk on for extended periods. They also help reduce noise levels, making them ideal for labs, offices, and control rooms where concentration is crucial.

💡 6. Aesthetic Appeal

Available in a range of colors and finishes, conductive rubber tiles can complement modern architectural designs while providing functionality. They can be installed in tile or sheet format to suit various layout requirements.

🏢 Applications of Conductive Rubber Tiles

Conductive rubber tiles are used across a wide range of industries due to their versatility and reliability.

🔧 1. Electronics Manufacturing Units

Static electricity poses a significant risk to electronic components during assembly. Conductive rubber flooring ensures safe dissipation of static charges, protecting microchips, circuit boards, and precision devices.

🧪 2. Laboratories and Research Facilities

In chemical and pharmaceutical labs, static control is essential for preventing ignition hazards and maintaining sterile conditions. Conductive tiles provide both chemical resistance and anti-static protection.

🖥️ 3. Data Centers and Server Rooms

Servers and network systems are highly sensitive to static discharges. Conductive flooring minimizes the risk of data corruption or equipment failure by maintaining a static-safe environment.

✈️ 4. Aerospace and Defense Industries

In aerospace manufacturing and assembly, even small electrical discharges can lead to critical failures. Conductive rubber tiles help maintain precision, safety, and compliance with ESD protection standards.

🏥 5. Healthcare and Medical Environments

Hospitals and diagnostic centers use conductive tiles in areas with sensitive electronic medical equipment to prevent static interference and ensure accurate readings.

🧰 Installation and Maintenance Tips

Installing conductive rubber tiles requires professional expertise to ensure proper grounding and conductivity.

🔩 Installation Best Practices

- Surface Preparation: The subfloor must be clean, dry, and level.

- Adhesive Selection: Use a conductive adhesive compatible with rubber materials.

- Grounding: Connect the tiles to a grounding point as per ESD flooring standards.

- Seam Sealing: Properly seal seams to prevent moisture or dirt infiltration.

🧽 Maintenance Guidelines

- Regularly clean using neutral pH cleaning solutions.

- Avoid wax or polish, which can interfere with conductivity.

- Periodically test conductivity to ensure long-term ESD protection.

🌟 Why Choose Conductive Rubber Tiles Over Other ESD Floors?

While ESD vinyl or epoxy coatings are common, rubber tiles offer superior comfort, durability, and sustainability. They are ideal for facilities that require both high performance and ergonomic benefits.Additionally, rubber’s natural resilience ensures a longer lifespan and lower maintenance cost compared to hard epoxy floors.

💬 Conclusion

Conductive rubber tiles combine the essential elements of safety, comfort, and durability—making them a practical investment for any static-sensitive workspace. Whether you’re designing an electronics lab, a data center, or a medical facility, this flooring solution provides long-term reliability while maintaining a professional and sleek look.

By reducing static discharge risks and improving overall workplace efficiency, conductive rubber tiles prove that the right flooring choice can make a powerful difference in both performance and protection.

Comments