In today's dynamic construction industry, builders, architects, and project managers are constantly seeking innovative materials and solutions that not only streamline construction processes but also enhance the performance and energy efficiency of structures. Sandwich PUF (Polyurethane Foam) Panels have emerged as a versatile and cost-effective choice for a wide range of construction applications. In this article, we will delve into the key features, benefits, and applications of Sandwich PUF Panels, shedding light on their transformative impact on modern construction.

What Are Sandwich PUF Panels?

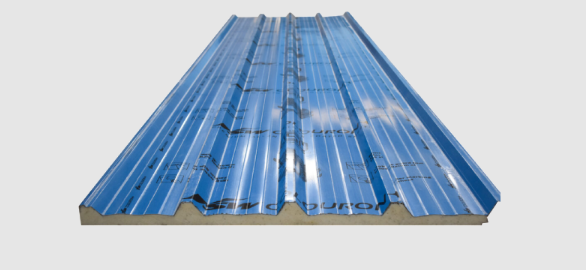

Sandwich puf panel are composite building materials consisting of a rigid foam core, typically made of polyurethane, which is sandwiched between two layers of metal, often steel or aluminum. The foam core is manufactured by injecting a polyurethane mixture into a mold, allowing it to expand and solidify, resulting in a lightweight yet incredibly sturdy panel.

Key Features of Sandwich PUF Panels

1. Outstanding Thermal Insulation: One of the standout features of Sandwich PUF Panels is their exceptional thermal insulation properties. The closed-cell polyurethane foam core minimizes heat transfer, helping maintain a comfortable temperature within buildings and significantly reducing energy consumption.

2. Durable and Weather-Resistant: These panels are designed to withstand harsh environmental conditions. They are corrosion-resistant and can endure extreme temperatures, making them suitable for both interior and exterior applications.

3. Quick and Easy Installation: Sandwich PUF Panels are known for their ease of installation, which helps reduce labor costs and construction time. They come in various sizes and thicknesses to accommodate diverse project requirements.

4. Fire Safety: Many Sandwich PUF Panels are available with fire-resistant coatings, enhancing the safety of the building and its occupants.

5. Customization Options: These panels can be customized to meet specific design and aesthetic preferences. This includes a variety of color choices and surface finishes to suit the project's requirements.

Benefits of Sandwich PUF Panels

1. Energy Efficiency: The superior thermal insulation of Sandwich PUF Panels contributes to substantial energy savings, as they reduce the need for heating and cooling, resulting in lower energy bills.

2. Cost-Effective: The fast installation process, reduced maintenance requirements, and energy savings make Sandwich PUF Panels a cost-effective choice for construction projects.

3. Eco-Friendly: These panels aid in reducing a building's carbon footprint by minimizing energy consumption and promoting sustainability.

4. Versatility: Sandwich PUF Panels are incredibly versatile and find applications across various sectors, including industrial, commercial, and residential construction, cold storage facilities, and cleanrooms.

Applications of Sandwich PUF Panels

1. Cold Storage Facilities: Sandwich PUF Panels are a popular choice for cold storage rooms and warehouses due to their excellent temperature control capabilities.

2. Cleanrooms: The pharmaceutical, biotech, and electronics industries utilize these panels to create controlled environments.

3. Commercial Buildings: These panels are widely used in commercial construction for roofing, wall cladding, and partitioning.

4. Residential Buildings: Homeowners opt for Sandwich PUF Panels to enhance energy efficiency and improve indoor comfort.

5. Industrial Structures: Warehouses, factories, and industrial buildings incorporate these panels to ensure stable and controlled environments.

In conclusion

Sandwich PUF Panels have become a cornerstone of modern construction, offering exceptional insulation, durability, and cost-effectiveness. Whether you're working on a commercial project, a residential development, or a specialized industrial facility, Sandwich PUF Panels provide a reliable and sustainable solution for all your construction needs. Elevate your construction projects with these advanced panels to experience the benefits of cutting-edge insulation technology.

For more info. visit us:

Comments