Many years back, the sheet metal manufacturing method was created. Hand tools or otherwise equipment were once used to fabricate many sorts of metals. Many new and helpful technologies and methods have emerged as a result of scientific and technical development to complete the metal manufacturing process. More advanced as well as high-quality tools are now accessible.

Various fabricating processes or systems, as well as metal forming tools or otherwise equipment, have indeed been created for industrial and technical applications as a result of scientific advances in engineering as well as metallurgy. Different sorts of products or things are created with the assistance of each method or approach. So, first, determine your needs, and then choose your manufacturing technique based on these criteria to ensure that you receive the greatest outcomes. Metal Fabrication Singapore is the best.

There is no question that sheet metal production and laser cutting need a great deal of focus and devotion. Customers come to fulfill a variety of goals. Each client must be treated individually and with importance by the sheet metal manufacturing firm. The first and most crucial job before beginning the sheet metal manufacturing process is to prepare the space or surface. It is correct that electricity passes through a cleaner metal efficiently and quickly. Metal Supplier Singapore has been doing an excellent work.

As a result, it is critical to clean as well as prepare the particular metal. All of the rust and dust must be thoroughly cleaned. A wire brush is indeed an excellent tool for cleansing metal. Before beginning the process, you might have the technician as well as the artisans measure the metal many times. Many people prefer Metal Works Singapore.

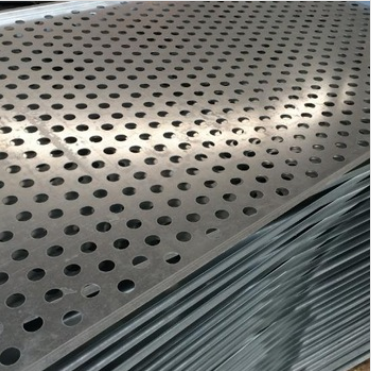

The sheet metal manufacturing operation is completed using a variety of technologies or techniques. Metals are used to create a variety of items. As a result, it is among the most critical services which most sectors demand. Sheet metal components are utilized for a variety of applications. It is utilized in the manufacture of aluminium cans and automobile panels. They are ductile in nature. That's why they are so much popular in the majority of businesses. Silver, copper, aluminium, and gold are all examples of highly ductile metals. These metals could be formed into a variety of shapes without breaking. Perforated panel is fantastic.

There are several sheet metal fabricating companies all around the world. The most recent and better equipment is employed to complete the procedure. To complete the work, many technologies are employed. Laser, jet, as well as other cutting-edge techniques are among them. No work is too little or too large to complete, from prototypes to higher volume manufacturing. To deliver the service properly and successfully, you must have the necessary experience and ability. Perforated sheet is used widely.

Ask your local specialized workshop for more details on fabrication or perhaps to have an item manufactured. They would be able to walk you throughout the fabrication process as well as provide a high-quality end product. Stainless Steel Fabrication Singapore is actually excellent.

Comments