A PSA nitrogen generator is a type of gas production system that uses Pressure Swing Adsorption (PSA) technology to separate nitrogen from compressed air. This process is highly efficient, cost-effective, and widely used across industries that require a reliable source of nitrogen. In this article, we’ll explore what a PSA nitrogen generator is, how it operates, its applications, and why it is a popular choice for businesses needing nitrogen gas solutions.

How Does a PSA Nitrogen Generator Work?

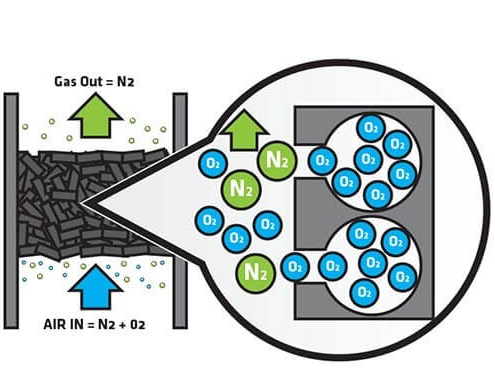

The operation of a PSA nitrogen generator is based on a simple but effective principle: the separation of nitrogen from air using molecular sieve adsorption. The generator works by pressurizing air, which is then passed through a series of adsorption towers filled with a molecular sieve material, such as carbon molecular sieve (CMS). This sieve selectively adsorbs oxygen and other gases from the air, allowing nitrogen to pass through as the output.

The process occurs in two main stages:

- Pressurization: The compressed air enters the first adsorption tower, where the molecular sieve adsorbs oxygen and other gases. The nitrogen is collected as the output.

- Depressurization: After a set time, the pressure in the tower is reduced, causing the adsorbed gases (mainly oxygen) to desorb and be expelled from the system. The second tower then goes through a similar process while the first tower is regenerated.

This cycle of pressurization and depressurization is repeated in a continuous manner, providing a steady supply of nitrogen gas.

Benefits of PSA Nitrogen Generators

1. Cost-Effective

One of the most significant advantages of a PSA nitrogen generator is its cost-effectiveness. Compared to traditional nitrogen production methods, such as liquid nitrogen deliveries or cryogenic air separation units, PSA technology offers a more affordable solution for generating nitrogen on-site. The primary costs involved are the initial installation and periodic maintenance, which are typically lower than the ongoing costs of buying nitrogen cylinders or tank deliveries.

2. On-Site Nitrogen Production

With a PSA nitrogen generator, companies can produce nitrogen gas on-site, eliminating the need for purchasing and storing large amounts of nitrogen. This not only saves money on transportation costs but also ensures a reliable, continuous supply of nitrogen without the delays associated with external gas suppliers.

3. High Purity Levels

PSA nitrogen generators can produce nitrogen at various purity levels, depending on the specific requirements of the application. Most systems can achieve nitrogen purities ranging from 95% to 99.99%. The purity of the nitrogen can be adjusted by fine-tuning the system’s settings to meet the exact needs of the process.

4. Compact Design

PSA nitrogen generators are typically compact and easy to install, making them ideal for businesses with limited space. Their modular design allows them to be easily integrated into existing industrial setups. This space-saving design makes them a viable solution for many industries, including laboratories, pharmaceuticals, and food packaging.

5. Low Maintenance

PSA nitrogen generators are relatively low-maintenance systems. The primary maintenance tasks include periodic replacement of the molecular sieve and routine checks on the compressor and valves. Unlike liquid nitrogen storage tanks or other nitrogen supply methods, PSA generators do not require large-scale infrastructure or complex refills, making them highly convenient and easy to manage.

6. Environmental Benefits

By using a PSA nitrogen generator, businesses can reduce their environmental footprint. The process of producing nitrogen on-site reduces the need for transportation and the associated carbon emissions. Moreover, the PSA process is energy-efficient, which helps lower overall operational costs.

Applications of PSA Nitrogen Generators

PSA nitrogen generators are used in a wide range of industries, thanks to their versatility, reliability, and efficiency. Some of the most common applications include:

1. Food and Beverage Industry

In the food industry, nitrogen is used for packaging, preservation, and ensuring product freshness. PSA nitrogen generators are used to supply nitrogen for modified atmosphere packaging (MAP), which extends the shelf life of food products by preventing oxidation and bacterial growth. This is especially critical in the packaging of perishable items such as meats, dairy, and ready-to-eat meals.

2. Pharmaceuticals and Healthcare

In the pharmaceutical industry, high-purity nitrogen is used for a variety of applications, including inerting, blanketing, and packaging. PSA nitrogen generators are used in laboratories for applications that require an oxygen-free environment, such as in the production of medicines and other health-related products. The controlled purity of nitrogen produced by PSA technology ensures the safety and quality of these sensitive products.

3. Electronics Manufacturing

PSA nitrogen generators are commonly used in electronics manufacturing to provide an oxygen-free atmosphere. Nitrogen is used for soldering, testing, and the protection of sensitive components from oxidation during the production process. The high purity of nitrogen produced by PSA systems helps maintain the integrity of delicate electronics.

4. Oil and Gas Industry

In the oil and gas industry, nitrogen is used for purging, pressurizing, and inerting pipelines, tanks, and equipment. PSA nitrogen generators are employed in various processes, such as preventing the formation of explosive mixtures in pipelines and tanks and ensuring the safety of offshore and onshore oil and gas operations.

5. Chemical Industry

The chemical industry relies heavily on nitrogen for various purposes, including inerting and preventing explosions during chemical reactions. PSA nitrogen generators offer an efficient way to generate the nitrogen required for these processes on-site, reducing reliance on external suppliers and improving process safety.

6. Metalworking and Welding

PSA nitrogen generators are also widely used in metalworking and welding applications. Nitrogen is used to prevent oxidation during cutting, welding, and heat treatment of metals. The availability of nitrogen produced on-site ensures that there is a constant supply of gas for these processes.

Conclusion: Why Choose a PSA Nitrogen Generator?

A PSA nitrogen generator provides numerous benefits, from cost savings and on-site nitrogen production to high purity levels and environmental advantages. Whether you are in the food and beverage industry, pharmaceuticals, electronics, or any other field that requires nitrogen, PSA technology offers a reliable, efficient, and sustainable solution.

Z-Oxygen Intelligent Device Co., Ltd., with its rich experience in air separation technology, offers high-quality PSA nitrogen generators designed to meet the diverse needs of customers worldwide. By choosing a PSA nitrogen generator from Z-Oxygen, businesses can enhance their operations while reducing costs and ensuring a continuous, high-quality supply of nitrogen gas.

Comments