stainless steel pipe fittings manufacturers in India s primarily used in piping policies for the carrier of fluids or waters. We trade steel pipe from a steel alloy including nickel as well as chromium, which gives stainless steel its corrosion-resistant properties.

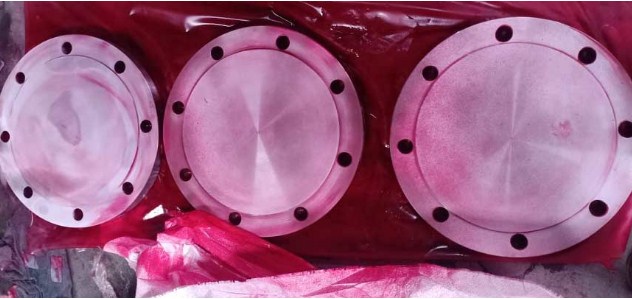

Stainless steel pipe is generally manufactured using a welding procedure or extrusion. The Stainless Steel Flanges manufacturer in Indiaprocedure involves constructive steel into a pipe silhouette and then fastening the seams jointly to hold the silhouette. Extrusion establishes a seamless commodity and pertains to heating a steel rod and then lancing it through the inner to establish a pipe.

The term “pipe” and “tube” are frequently used to interpret the same commodity, but it is crucial to know the discrepancy. Though they interest the same cylindrical silhouette, steel tubes are measured by the internal diameter (ID), whereas steel canals are gauged by the outside diameter (OD) and wall thickness. Another carbon steel pipe fittings manufacturers in indiais that ducts are used to transfer fluids and gases, while tubes are utilised to build fractions or structural ingredients.

Totten Tubes gives stainless steel tube that is welded and generated to A105 Flangeand ASME SA-312and are given in 304/L and 316/L degrees of steel. We commonly make our welded stainless pipe in quantities ranging from 1/8" nominal to 24" nominal. We also give seamless stainless steel pipe generated to A105 Fittings and requested in both 304/L and 316L grades of steel. The minor size range for our seamless stainless tubes.

The choice between equipments is highly conditional upon how you will use the tube and the climate in which the pipe will be established.

Type 304 stainless steel is maybe the most Carbon Steel Flanges manufacturers in India

type used because it is corrosion-resistant and simple to sanitise. This category of steel is frequently used for nutrition and juice applications or in house dressings.

Stainless steel is commonly and widely available used in many businesses where its courage and corrosion opposition are invaluable. It is also used where heat and chemical opposition, cleanliness and lower supervision costs are crucial. Whether you are a first-time architect or a highly-experienced building engineer looking for a decent type of material, the industry in which you work will most likely require a certain degree of stainless to be utilised.

There are many advantages to each equipment irrespective of the planned application, encompassing strength, weight, versatility and of course, expense. Some of the benefits of using steel pipe instead of other equipments are strength, versatility and lack of reactivity to some chemicals. Stainless pipe also commonly needs less rehearsal time before any committee; carbon steel is normally coated before shipment as a protection and this defensive coating has to be removed before any committee or welding. Stainless pipe also is usable as welded tubing, which is generally less costly and more quickly usable than seamless tubing, but the dressing regulations may restrict the use of welded pipe as the seam was deemed to be a weak area in the pipe. With exceptional manufacturing methods in the last various years, a weld seam is much smaller of a problem than what it used to be. It is always a decent idea to check for any pressure-related regulations or other pertinent issues before you choose between welded and seamless stainless ducts.

Comments