CNC technology has transformed the way industries and individuals approach design and manufacturing. Among the many variations of these advanced machines, the 3 axis CNC router stands out as one of the most widely used and accessible. Whether in woodworking, signage, or prototyping, the 3 axis CNC router provides an ideal balance of precision, efficiency, and versatility. For businesses aiming to streamline production or hobbyists eager to expand their creative capabilities, understanding the value of a 3 axis CNC router is essential. To get more details, visit here https://www.omni-cnc.com/3-axis-cnc-router/.

What is a 3 Axis CNC Router?

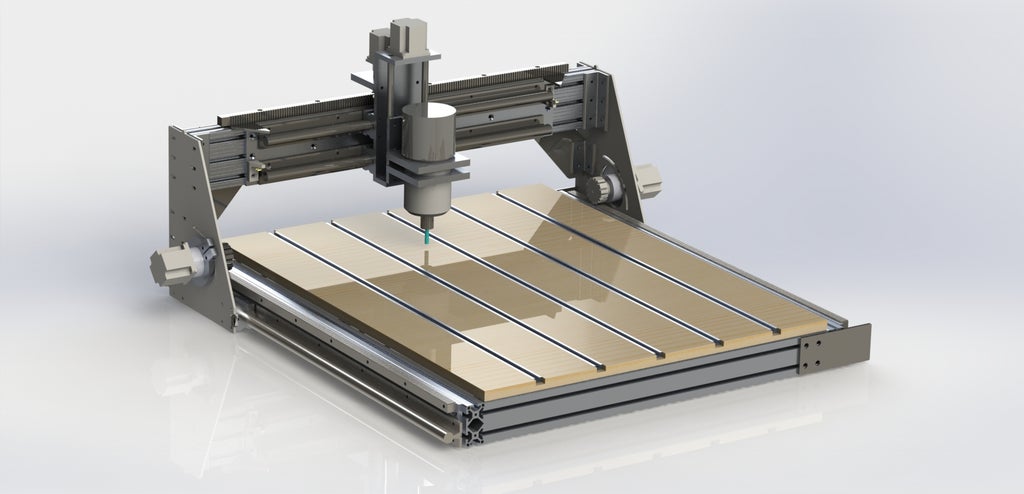

A 3 axis CNC router is a computer-controlled cutting machine that operates along three axes: X, Y, and Z. The X and Y axes allow the machine to move horizontally, while the Z axis controls vertical movement. This enables the router to cut, carve, and engrave materials with impressive accuracy.

Because of its ability to move in three dimensions, a 3 axis CNC router is capable of producing flat, detailed, and layered designs. It cannot achieve the complex undercuts possible with 4 or 5 axis machines, but for most applications, it provides more than enough capability at a lower cost. This makes it an attractive choice for workshops that want precision without the steep investment of higher-axis machines.

Key Features of 3 Axis CNC Routers

The strength of the 3 axis CNC router lies in its design simplicity and adaptability. These machines typically include a solid table surface, a powerful spindle, and software that translates digital designs into machine movements. The combination ensures repeatable accuracy, even on projects that require fine detail.

Many 3 axis CNC routers also feature automated tool changers, dust collection systems, and vacuum hold-downs that secure materials during operation. These additions enhance workflow efficiency and create a safer, cleaner environment for operators. For small workshops or large-scale industries, the machine’s versatility makes it a valuable investment.

Advantages of Using a 3 Axis CNC Router

The popularity of 3 axis CNC routers comes from their wide range of benefits. Precision is at the top of the list, as the machine ensures that designs are replicated exactly as intended. Efficiency is another advantage, as projects that might take hours of manual effort can be completed quickly and with consistent quality.

Another significant benefit is versatility. A 3 axis CNC router can handle wood, plastics, composites, foam, and even aluminum. This allows operators to take on diverse projects without needing separate machines for different materials. The combination of cost-effectiveness and flexibility makes the 3 axis CNC router an appealing choice across industries.

Applications in Different Industries

The applications of 3 axis CNC routers span a wide spectrum. In woodworking, they are used to create furniture, cabinetry, decorative carvings, and custom designs. In signage, the routers produce precise lettering, logos, and intricate designs across a variety of materials. Prototyping industries also rely on these machines to quickly and accurately develop models that help bring ideas to life.

Education is another area where 3 axis CNC routers are making an impact. Schools and training centers use them to teach students about modern manufacturing methods, providing hands-on experience with technology that prepares them for careers in engineering, design, and craftsmanship.

Choosing the Right 3 Axis CNC Router

Selecting the right 3 axis CNC router requires careful consideration of workshop needs. Table size determines the maximum dimensions of the materials that can be used, while spindle power affects how quickly and effectively the machine can cut through tougher materials. Software compatibility is equally important, as smooth integration with popular design programs simplifies the workflow.

Buyers should also pay attention to manufacturer support, training resources, and warranty options. A high-quality machine backed by reliable service ensures that the investment continues to deliver results for years to come.

The Future of 3 Axis CNC Routers

While 4 and 5 axis machines are gaining traction in highly specialized industries, the 3 axis CNC router remains a cornerstone of workshops worldwide. Its balance of affordability, precision, and usability ensures that it will continue to play a vital role in design and manufacturing. With advancements in software, automation, and connectivity, modern 3 axis CNC routers are becoming even more efficient and user-friendly.

Conclusion: A Smart Investment for Precision and Creativity

The 3 axis CNC router is more than just a machine—it is a gateway to efficiency, precision, and innovation. From professional workshops to home studios, it empowers users to achieve results that would be difficult or impossible by hand. Its ability to work across multiple industries and handle a wide range of materials makes it a versatile tool for anyone serious about design and production.

For businesses seeking to expand capabilities and individuals looking to elevate their craft, investing in a 3 axis CNC router is a step toward greater creativity and efficiency. With its proven reliability and growing accessibility, it remains one of the most valuable tools in modern manufacturing.

.png)

Comments