Introduction

The Spain Injection Molding Machine Market has been rapidly evolving, with significant contributions from global players in the industry. One such company that has been at the forefront of technological advancements and strategic developments is The Japan Steel Works Ltd. (JSW). Known for its long-standing reputation in manufacturing high-performance machinery, JSW has consistently integrated cutting-edge technologies and innovative practices into the injection molding space. This article explores the strategies, emerging innovations, and developments adopted by the Spain injection molding machine market, with a particular focus on the contributions of JSW.

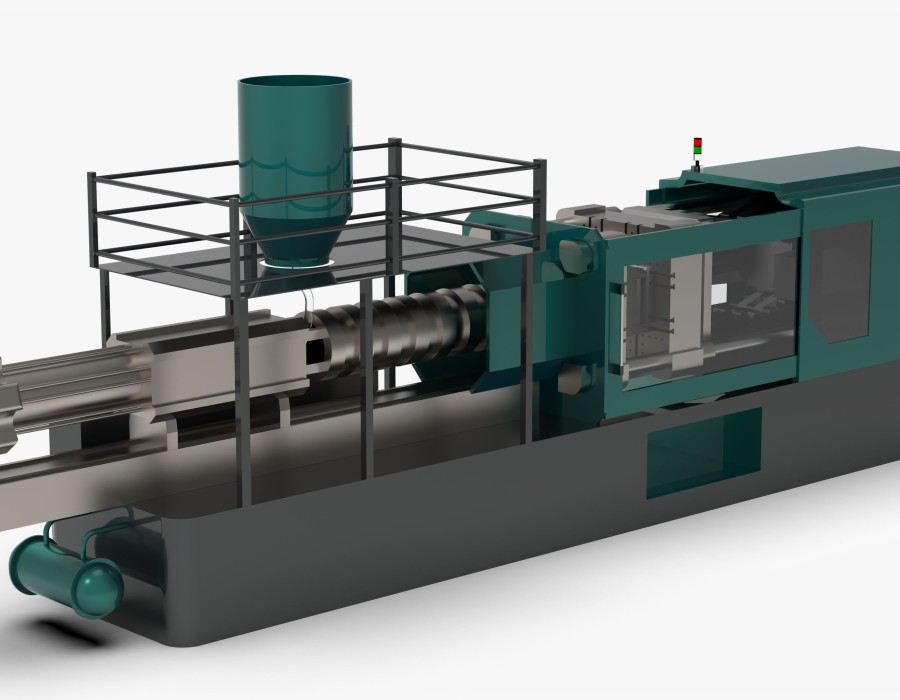

The Spain Injection Molding Machine Market Overview

Spain’s manufacturing sector has seen steady growth, particularly in industries like automotive, packaging, and consumer electronics. As these sectors expand, the demand for high-efficiency injection molding machines has risen. These machines are integral to producing plastic components with precision and scalability. The Spanish market has witnessed a shift towards automation, energy efficiency, and precision, creating opportunities for global industry leaders like JSW to expand their influence.

JSW’s Strategy in the Spanish Market

JSW’s strategy in Spain is centered around the integration of advanced technologies to enhance the performance and efficiency of injection molding machines. A key element of this strategy is their focus on energy-efficient solutions, which resonate well with European companies that are increasingly focusing on sustainability. The company has also adopted a localized approach, offering customized solutions tailored to the needs of Spain’s diverse industries, such as automotive, medical, and consumer goods.

JSW’s emphasis on after-sales service and support further strengthens its position in the Spanish market. By offering comprehensive maintenance programs and technical support, the company has built a loyal customer base that values reliability and long-term partnerships.

Emerging Innovations in Injection Molding Technology

One of the driving factors in the Spain injection molding machine market is the continuous innovation being introduced to increase machine efficiency, reduce environmental impact, and improve product quality. JSW has played a key role in these advancements, particularly through the development of advanced servo motor technologies and hybrid injection molding machines.

1. Energy-Efficient Machines

JSW has invested heavily in developing energy-efficient injection molding machines, which have become a significant selling point in Spain. These machines use less energy while maintaining high-performance levels, a critical factor as European companies seek to reduce their carbon footprints. JSW’s ECO series of injection molding machines, for example, features energy-saving technologies that drastically reduce energy consumption compared to traditional machines.

2. Smart Manufacturing and Automation

Automation is another major trend in the injection molding sector. JSW’s implementation of smart manufacturing solutions, including robotics and artificial intelligence (AI), is shaping the future of the industry. Their J-AD series, for instance, integrates AI and automation to optimize the molding process, ensuring faster cycle times and greater precision. This also reduces human error and the need for manual intervention, which is crucial for high-volume production lines in Spain’s automotive and electronics sectors.

3. Hybrid Technology

JSW has also embraced hybrid injection molding technologies that combine the advantages of hydraulic and electric machines. These hybrid models offer a perfect balance of speed, energy efficiency, and precision, making them ideal for companies in Spain that require high-quality, high-speed production while minimizing operational costs.

JSW's Commitment to Sustainability and Green Manufacturing

The focus on sustainability has been a key aspect of JSW’s strategy in Spain. The company’s dedication to eco-friendly production processes aligns with the increasing environmental regulations in Europe. JSW has adopted several green manufacturing initiatives, including the use of recyclable materials and energy-efficient production lines, as well as reducing waste during the molding process. These innovations help clients in Spain meet stringent environmental standards while remaining competitive in a global market.

Local Collaboration and Market Adaptation

JSW’s success in the Spanish market can also be attributed to its ability to collaborate with local partners and adapt to the unique needs of Spanish industries. By forming alliances with local distributors and service providers, JSW ensures seamless integration of its machines into Spanish factories. Furthermore, the company conducts extensive training programs for Spanish engineers and technicians, helping them maximize the potential of the technology and ensuring that customers can quickly adapt to new systems.

Conclusion

The Spain injection molding machine market is undergoing significant transformations driven by advancements in technology and evolving industrial needs. Companies like The Japan Steel Works are spearheading these changes through their commitment to innovation, energy efficiency, and customer-centric strategies. JSW’s efforts to introduce smart, energy-efficient, and sustainable injection molding solutions position them as a key player in the market, meeting the demands of Spain’s diverse manufacturing sectors. As the industry continues to evolve, JSW’s adaptability and focus on technological advancements will likely continue to shape the future of injection molding in Spain.

Comments