In recent years, the beauty and wellness industry has undergone a remarkable transformation. One of the most critical and dynamic areas driving this change is personal care product manufacturing. With rising consumer awareness, demand for transparency, and increasing interest in sustainability, manufacturing processes are no longer limited to mass production. Today, they're part of a larger narrative around health, ethics, and environmental responsibility.

Understanding Personal Care Product Manufacturing

At its core, personal care product manufacturing involves the formulation, production, and packaging of items intended for daily hygiene and grooming. These products range from skin creams, shampoos, and body washes to deodorants, facial masks, scrubs, and more. The process spans several stages—beginning with research and development, followed by ingredient sourcing, formulation testing, production, quality assurance, and packaging.

Unlike other sectors, this industry is highly regulated due to the intimate nature of the products involved. Manufacturers must adhere to stringent safety and hygiene standards while also navigating consumer trends, ingredient innovations, and evolving market needs.

From Lab to Shelf: The Key Stages

1. Research and Development (R&D)

The first step in personal care product manufacturing is conceptualization and formulation. Here, chemists and product developers experiment with different ingredient combinations to achieve the desired results—whether it's skin hydration, anti-aging effects, or gentle cleansing.

Modern R&D also involves extensive consumer trend analysis. Ingredients like hyaluronic acid, niacinamide, and plant-based oils are popular today due to their proven benefits and cleaner safety profiles.

2. Sourcing Ingredients

Today’s consumers demand transparency about what goes into their products. This has led to a surge in demand for ethically sourced, natural, and certified ingredients. Manufacturers now often work with suppliers who provide traceable raw materials, free from parabens, sulfates, and synthetic fragrances.

Eco-certifications and cruelty-free labels have also become important benchmarks during this stage of the process.

3. Formulation Testing

Once a prototype is created, it undergoes rigorous testing for texture, fragrance, pH balance, shelf life, and microbiological stability. Dermatological testing and sensitivity trials are often conducted to ensure that the product is safe for different skin types.

Compliance with national and international cosmetic regulations is mandatory before the product can move into full-scale production.

4. Manufacturing and Quality Assurance

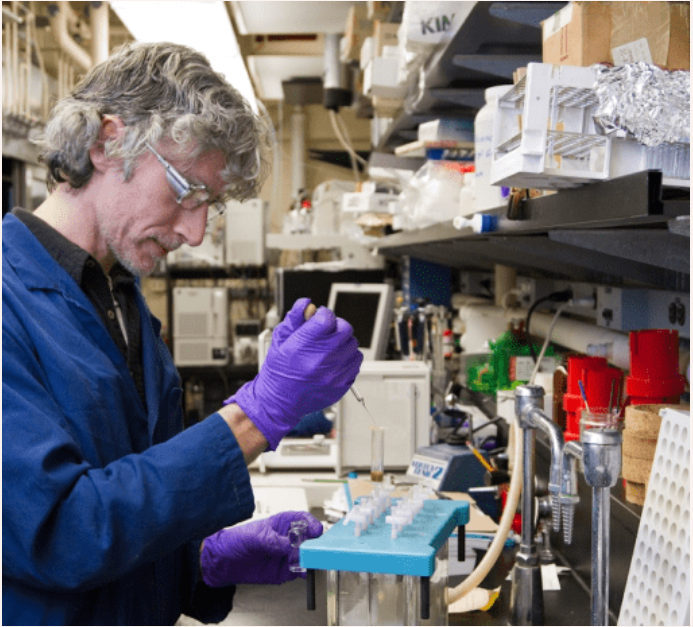

During actual production, high-grade equipment is used to mix, heat, and fill products in a controlled environment. Automation and batch-tracking ensure consistency in every unit produced. Good Manufacturing Practices (GMP) are the gold standard here, ensuring quality control and regulatory compliance.

Personal care product manufacturing facilities often maintain strict hygiene protocols, including HEPA-filtered air systems, sanitized machinery, and staff equipped with personal protective equipment.

5. Filling and Packaging

Packaging is more than just aesthetic—it affects the product’s shelf life, usability, and environmental impact. As sustainability becomes more central, manufacturers are shifting toward recyclable, biodegradable, or refillable packaging.

Innovative packaging solutions like airless pumps, glass containers, and post-consumer recycled plastics are now widely used.

The Rise of Clean and Sustainable Manufacturing

One of the most significant developments in personal care product manufacturing is the shift toward “clean beauty.” Consumers increasingly scrutinize ingredient labels, seeking formulations free from harmful chemicals and environmentally degrading compounds. In response, manufacturers are adopting clean-label approaches—emphasizing plant-derived ingredients, low-impact preservatives, and ethical testing methods.

Sustainability also plays a key role in the supply chain. From reducing water usage during production to investing in renewable energy, manufacturers are being called to make greener choices. Waterless products like solid shampoos and concentrated serums are gaining traction for their minimal environmental footprint.

Customization and Private Labeling

As the market becomes more segmented, the demand for customized and niche products has grown. This is where private labeling becomes a game-changer. In this model, businesses can collaborate with manufacturers to develop personalized product lines that cater to specific demographics or skin concerns.

Private-label solutions are often faster to market and cost-effective, making them ideal for startups and influencers entering the beauty space. The manufacturer handles the heavy lifting—formulation, compliance, and production—while the brand focuses on marketing and customer engagement.

Regulatory and Compliance Considerations

A crucial part of personal care product manufacturing is navigating regulatory frameworks. Depending on the market, manufacturers must comply with the FDA (in the U.S.), BIS (in India), EU Cosmetic Regulation, and other local authorities.

Labeling requirements, banned substance lists, and allergen disclosures are some areas where precision is non-negotiable. Non-compliance not only risks product recalls but also damages brand trust.

Innovation Through Technology

Technology is shaping the future of personal care production. Artificial intelligence is being used to predict consumer preferences and suggest formulations. Automation ensures precision in mixing and filling, while blockchain is emerging as a tool for ingredient traceability.

Some manufacturers are even investing in 3D printing for packaging and sensor-based technologies that allow for real-time product performance analysis.

Challenges Facing the Industry

While the industry is full of potential, it's not without challenges. Some key hurdles include:

- Ingredient sourcing: Procuring consistent, high-quality natural ingredients can be difficult and expensive.

- Shelf-life stability: Natural formulations often have shorter shelf lives and require innovative preservation methods.

- Consumer skepticism: “Greenwashing” has made consumers wary. Authenticity and transparency are now more critical than ever.

Final Thoughts

The world of personal care product manufacturing is complex, fascinating, and evolving at an unprecedented pace. From clean formulations and eco-friendly packaging to tech-driven production and custom branding, the future looks both innovative and responsible.

Whether you are a consumer keen to understand how your favorite products are made or an entrepreneur looking to launch your own skincare line, staying informed about the manufacturing landscape is essential. As consumer expectations rise, manufacturers must continue to adapt, innovate, and lead with integrity.

Comments