Understanding Perforated Sheet Metal

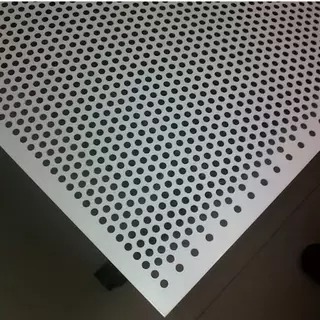

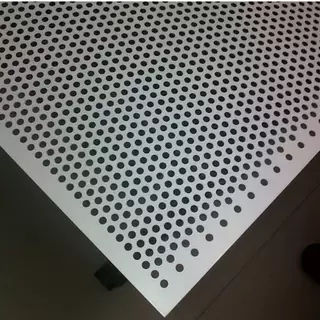

Perforated sheet metal is created by punching or stamping holes, slots, or other patterns into a metal sheet. The resulting product is a metal sheet with a series of holes or perforations arranged in a specific pattern. These perforations can vary in size, shape, and distribution, allowing for a high degree of customization to meet specific needs.

The most commonly used metals for perforated sheets include stainless steel, aluminum, copper, and carbon steel. These metals are chosen for their durability, corrosion resistance, and ability to withstand various environmental conditions. Perforated Sheet Metal The selection of metal and the perforation pattern depends on the intended application and the desired characteristics, such as airflow, light transmission, or weight reduction.

Advantages of Perforated Sheet Metal

Aesthetic Appeal: Perforated sheet metal offers a visually appealing solution for architectural and design projects. Its ability to blend functionality with aesthetics makes it a popular choice for facades, interior design, and decorative elements. The variety of patterns and finishes available allows designers to create unique and eye-catching designs.

Versatility: One of the most significant advantages of perforated sheet metal is its versatility. It can be used in various applications, including soundproofing, filtration, ventilation, and screening. The flexibility in design and material choice means that it can be adapted to almost any project requirement.

Enhanced Functionality: Perforated sheet metal improves functionality in applications where airflow, light, or sound needs to be controlled. For example, it is commonly used in HVAC systems to allow air to pass through while blocking debris. In acoustic panels, perforated metal helps reduce noise levels by absorbing sound waves.

Durability and Strength: Despite the presence of perforations, sheet metal retains much of its original strength and durability. This makes it suitable for applications that require a robust material that can withstand physical stress and environmental conditions. Additionally, metals like stainless steel and aluminum provide excellent corrosion resistance, further enhancing the longevity of the product.

Sustainability: Perforated sheet metal is an environmentally friendly option, as it can be made from recyclable materials and reduces the overall weight of structures, leading to lower energy consumption during transportation and installation. Its durability also means that it has a long lifespan, reducing the need for frequent replacements.

Applications of Perforated Sheet Metal

Perforated sheet metal finds applications in a wide range of industries:

Architecture: Used in facades, sunshades, and decorative panels to combine functionality with aesthetics.

Automotive: Employed in grilles, exhaust systems, and interior components for weight reduction and improved airflow.

Industrial: Utilized in filtration systems, ventilation, and noise control in machinery and equipment.

Agriculture: Applied in screening, sorting, Aluminium Perforated Sheet and drying processes to enhance efficiency and productivity.

Retail: Often used in shelving, displays, and signage for both functional and decorative purposes.

Comments