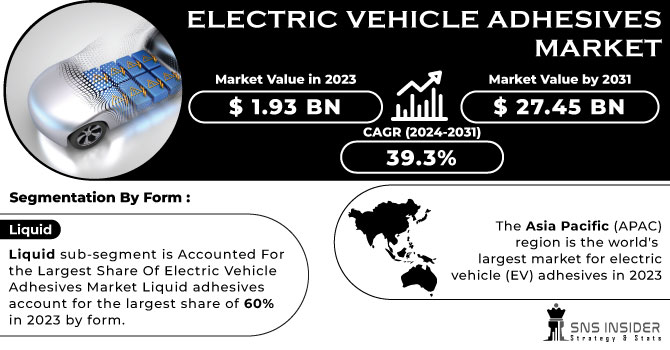

The SNS Insider report indicates that the Electric Vehicle Adhesives Market Size was valued at USD 1.93 billion in 2023 and is expected to reach USD 27.45 billion by 2031 and grow at a CAGR of 39.3% over the forecast period 2024-2031. The electric vehicle (EV) adhesives market is experiencing rapid growth as the automotive industry transitions towards more sustainable and efficient mobility solutions. EV adhesives play a critical role in vehicle manufacturing by offering lightweight, durable, and flexible bonding solutions that replace traditional mechanical fasteners. These adhesives contribute to the overall reduction in vehicle weight, enhancing energy efficiency and extending the driving range of electric vehicles. With the increasing demand for EVs driven by stringent emissions regulations, government incentives, and consumer preference for environmentally friendly transportation, the need for specialized adhesives that ensure structural integrity and safety is becoming paramount.

Manufacturers are developing innovative adhesives with enhanced thermal management properties to address the unique challenges posed by EV battery systems, such as heat dissipation and vibration resistance. Additionally, there is a growing trend towards eco-friendly and recyclable adhesives that align with the automotive industry's broader goals of reducing environmental impact throughout the vehicle's lifecycle. These advancements not only improve the performance and safety of electric vehicles but also support the industry's commitment to sustainability. As the adoption of electric vehicles continues to accelerate, the market for EV adhesives is poised for significant growth, driven by ongoing innovation and the increasing demand for high-performance, sustainable bonding solutions.

Request for Sample Report @ https://www.snsinsider.com/sample-request/2367

KEY PLAYERS

· PPG Industries, Inc.

· L&L Products

· Henkel

· Ashland

· Permabond (UK0)

· 3M

· Wacker Chemie AG

· H.B. Fuller

· Bostik SA – An Arkema company

· Sika AG

· Jowat SE & Other Players.

Market Report Scope –

There are a number of benefits to be gained by the application of electrical vehicle adhesives, even distribution of stress and load between bonded joints; increased strength as well as effective and flexibly shaped parts. Increasing demand for EVs, the growing use of effective and efficient bonding solutions in EV's as well as a rising trend towards adhesives to assemble batteries are factors that have been driving this market growth. Significant growth opportunities for the players in electric vehicle adhesives are anticipated as a result of growing demand for sustainable, ecotoxic solutions and adoption of self-driving cars.

Market Growth Factors –

Electric Vehicle Adhesives Market has battery packs are expected to gain significant momentum in terms of sustainability, durability and security. Currently, it is expected that the development of new thermal conductive interface materials for effective assembly of electric and hybrid battery cells will be pursued by companies active on the current market in electrical vehicle adhesives. The need for effective and advanced bonding solutions in this sector has been stimulated by the increasing demand for electric vehicles. The role of effective bonding solutions is becoming increasingly important as EV manufacturers strive to improve vehicle performance, durability and security. The unique construction of electric vehicles is one key factor driving the demand for enhanced bonding solutions. In order to maximize energy efficiency and extend the life of electric vehicles, lightweight materials such as composites and aluminum are often used.

Segmentation Analysis –

By Application

· Powertrain

· Exterior

· Interior

By Resin Type

· Epoxy

· Polyurethane

· Silicones

· Acrylics

· Others

By Vehicle Type

· Electric Car

· Electric Bus

· Electric Bike

· Electric Truck

By Substrate

· Plastic

· Composite

· Metals

· Others

By Form

· Liquid

· Film & Tape

· Others

Electric vehicle adhesives are divided into the external, interior and powertrains depending on application. The largest share of the electric vehicle adhesives market is expected to be accounted for by the powertrain segment in 2023. With the integration of a wide variety of new electrical and electronics components, the electric vehicle's propulsion system is constantly developing. In order to protect the system, there is a growing need to use effective thermal and electrical insulation adhesives in the powertrain.

Electric vehicle adhesives are classified according to the type of vehicles, such as trucks, buses, bicycles and automobiles. The largest share of the electric vehicle adhesives market is anticipated to be accounted for by an electric car segment between 2023 and 2025. The increase in the adoption of electrical vehicles, which has contributed to the growth of the adhesives market, is driving this segment's high market share. The use of lightweight materials in electric cars is increasing.

Key Regional Development –

The Asia Pacific region is expected to have the highest share of the market for automotive adhesive in 2023. The Asia Pacific region is the fastest growth market for electricity vehicles. Significant uptake of electric vehicles has been seen in countries such as China, Japan and South Korea due to government incentives, policy support and a strong focus on reducing greenhouse gas emissions. The increased demand for EV adhesives is a direct result of the increase in electric vehicle production and sales. The Asia Pacific region is a major production base for the automotive sector, including electric cars. In countries like China and Japan, many of the leading electric vehicle producers and suppliers have production facilities. These facilities require a substantial supply of adhesives for various EV components, creating a robust market for EV adhesives in the region.

Key Takeaway’s–

The increasing investment in the EV market, driven by a high demand for two wheelers in emerging countries, has led to increased adoption of better-quality adhesives during the coming years. Adhesives can be used to reduce the weight of an electric vehicle. The ideal replacement for mechanical fasteners in electric vehicle batteries is electric vehicle adhesive. In the design of electric vehicle batteries, adhesives are usually used to reduce or at least make up for excessive metal fasteners. This will help improve the efficiency of electrical energy of vehicles.

Recent Developments -

PPG announced the opening of its battery pack application facility BPACin Tianjin, China on June 23, 2023. The facility, valued at $30 Bn, encompasses a comprehensive array of capabilities for evaluating the practicality of PPG coatings technologies, materials, and systems in the context of electric vehicle battery packs. This will allow new electric vehicle technology to be developed faster for customers.

Henkel Adhesives demonstrated a firm commitment to further expansion through the use of electric vehicle EV batteries during Dec 2022. In collaboration with the automotive industry and battery producers, Henkel has been active in research efforts aimed at improving EV performance by exploiting major technology breakthroughs.

Related Reports:

https://finance.yahoo.com/news/phenolic-resin-market-reach-usd-175700013.html

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

Comments