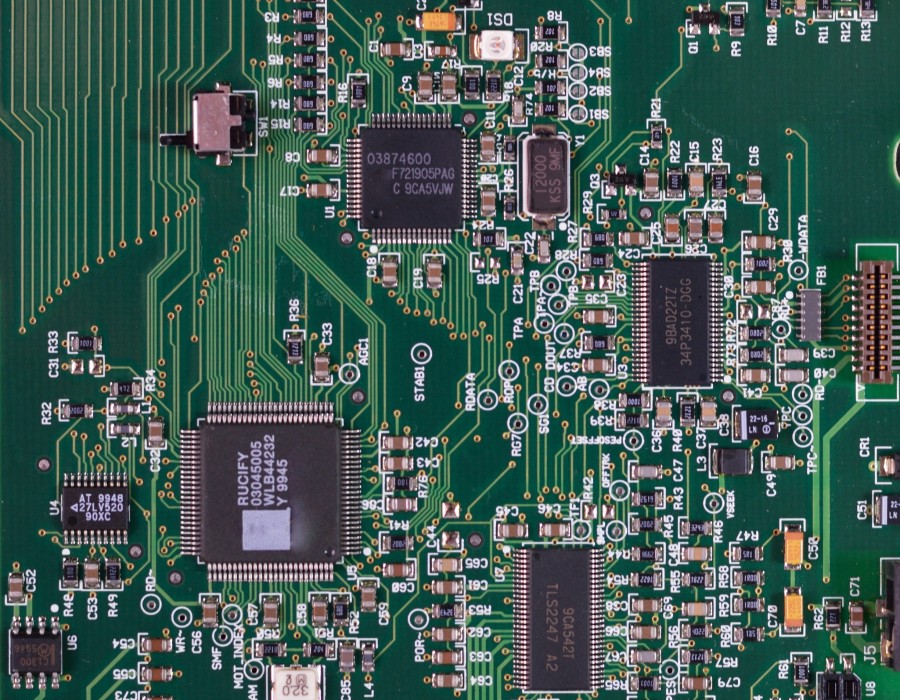

In today’s high‑tech environments think data centers, control rooms, semiconductor fabs, and cleanrooms unseen threats can quietly undermine operations. One of the most insidious? Corrosion of electrical components. That's where electronics corrosion monitoring steps in, offering critical visibility and protection.

Why electronics corrosion monitoring matters

Corrosion in delicate electronics often results from airborne contaminants remnants of manufacturing flux, infiltrating sulfur compounds, or humidity-induced internal oxidation. Particularly with the widespread adoption of RoHS regulations, electronics have become notably more vulnerable. Such corrosion doesn’t just hamper performance it slashes service life and voids warranties.

By adopting Electronics Corrosion Monitoring, organizations can identify corrosive threats early, safeguard equipment, reduce wastage, and minimize unexpected downtime.

Active vs. Passive: Tailoring the right approach

AQOZA provides two core methods of electronics corrosion monitoring, each serving distinct needs:

Active (Online) Corrosion Monitoring

With devices like the AQOZA CORROSENSE Active 2.0 and A01, real‑time monitoring becomes a reality. These units employ ER (Electrical Resistance) technology—measuring how metal tracks (copper and silver) degrade to precisely calculate corrosion rates. Data is categorized per ANSI/ISA‑S71.04 standards into G1 (Mild), G2 (Moderate), G3 (Harsh), or GX (Extreme) levels. With touchscreen displays, downloadable data, and support for PoE or multiple communication protocols, active units are ideal where uninterrupted monitoring is critical think server rooms, control centers, and datacenters.

Passive Corrosion Monitoring (Coupons)

The ER-based corrosion coupons offer a budget-friendly yet equally precise snapshot. Installed on-site for a 30-day exposure, these coupons are then analyzed in AQOZA’s lab to reveal copper and silver corrosion via resistance measurement. Especially useful for facilities just initiating a monitoring program, this method is straightforward, power-free, and excellent for periodic audits.

Broader impact of robust electronics corrosion monitoring

- Cost-effective maintenance — Real-time and proactive insights help avoid expensive hardware replacements and extend equipment life.

- Operational continuity — Prevent corrosion-related equipment failures that can cripple operations.

- Better environmental control — Monitoring fuels effective corrosion control, like filtration units that remove corrosive gases before they pose a risk.

- Standards-based reliability — All units align with ANSI/ISA‑S71.04, ensuring trusted, globally recognized corrosivity classification.

Integrating electronics corrosion monitoring into the larger maintenance ecosystem especially alongside AQOZA’s Corrosion Control Units ensures a corrosion-free environment and gives you confidence in long-term reliability.

Comments