Are you searching for a contract manufacturing business to help you with metal fabrication? Metal is formed into a vast variety of products using a variety of techniques, including shearing, drilling, grinding, punching, as well as bending, to mention a few. Metal components made in this manner are employed in a wide range of goods. Because the quality as well as availability of made metal components will affect your business, you'll actually need to choose the best manufacturing firm feasible.

Look for a firm that provides - Custom designing services with the assistance of an in-house staff that utilises CAD software. You must be able to find a part that meets your exact requirements. In addition, the organisation should provide you with prompt feedback on any design flaws that arise so that fixes may be addressed as soon as possible. Angle Bar is used widely.

- The ability to produce any design of specifically you’re choosing. This is usually attainable if the firm has the necessary equipment as well as raw materials for a variety of industrial processes. Examine whether the firm has the necessary equipment to provide you with innovative production methods such as laser cutting, electro discharging machining (EDM), waterjet cutting, and so on. C Channel is pretty reliable.

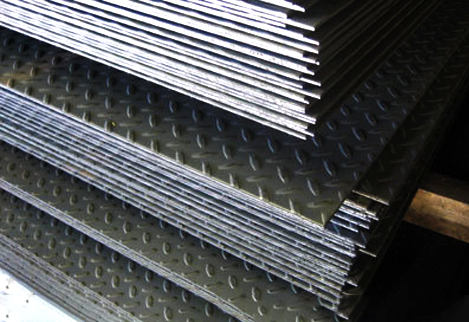

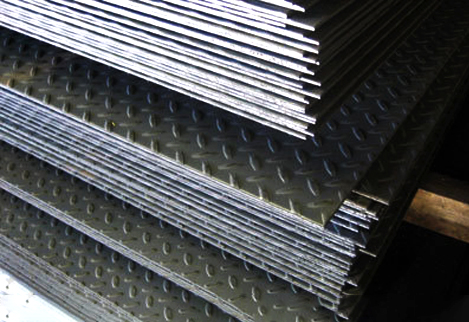

- Quick manufacture so that you have your final items as soon as possible. This is critical, because else your own manufacturing process will be slowed owing to a shortage of parts. Chequered Plate is outstanding.

- Simple ordering procedure, especially if you really can make the purchase online and provide the product design to specifically the firm via email. Flat Bar is a fantastic choice.

- Dependability, with the completed product being precisely what you expected. Furthermore, the items should arrive within the time frame promised to you so that just you don't have to waste time following up with the organisation. Hollow Section is the best.

- Outstanding value for money. The product must be priced cheap enough that you can maintain the ultimate price of your product as low as possible. This will assist you in maintaining a high level of profitability. If the provider offers inexpensive pricing from the start, you would save time seeking for quotes. I Beam Size is pretty good.

When all of the components have been prepped, they are assembled. Welding is particularly sometimes done by a highly experienced worker; however programmable spot welders are becoming increasingly popular. Programmable welders, often called as robots, making the production process safer, more cost-effective, and more efficient. Riveting as well as threaded fasteners may also be utilised to assemble the items in some cases.

Some items would require further finishing. The product might be sandblasted as well as painted, or it might be powder coated. Powder coating is indeed a form of metal coating in which the metal is coated with a dry powder instead of a liquid. It is actually cured at higher temperatures to bond it to the material and create a very tough, hard skin. Typically, the final product is evaluated and shown to the consumer.

Comments