What is a Metallurgical Microscope?

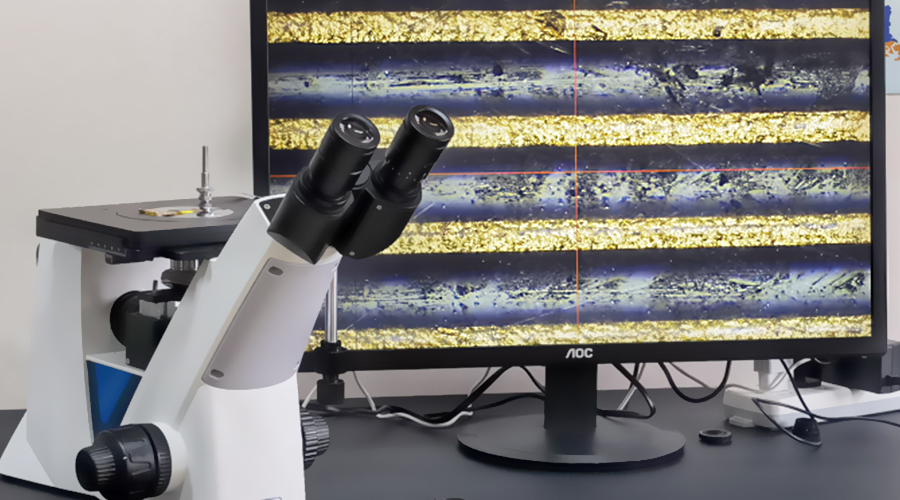

Metallurgical Microscopes, also named as Materials Microscopes, are mainly used in metallography, forensics, plastics processing, metal detection, semiconductor materials, laser systems, solar cells using thin-film and wafer technology, and many other fields of material science. Whether they are optical or digital, metallurgical microscopes can be used in virtually any industry or field of study that must observe glossy metal surfaces. These include metallurgy, mineralogy, and gemology. Manufacturers also utilize digital or optical metallurgical microscopes to inspect materials and components for signs of defects or wear. Some of the types of samples you might look at with a metallurgical microscope include metal parts, fiberglass, industrial manufacturing failures in materials, carbon fiber, plastics and concrete.

Microscopic analysis method is a very important research method in the field of material science. It can observe and study the structural details and defects in materials such as metals that cannot be observed by macroscopic analysis methods. Metallographic microscope is the main tool for microscopic analysis.

Metallurgical Microscopes may look similar to compound biological microscopes, but they differ in a number of ways. Using a metallurgical microscope allows the user to view samples at high magnification (up to 500x and 1000x), without any light passing through the sample the way a biological sample is viewed. Stereo microscopes are another option when reflected illumination is required, however metallurgical microscopes provide a much higher resolution and magnification than a stereo microscope would provide.

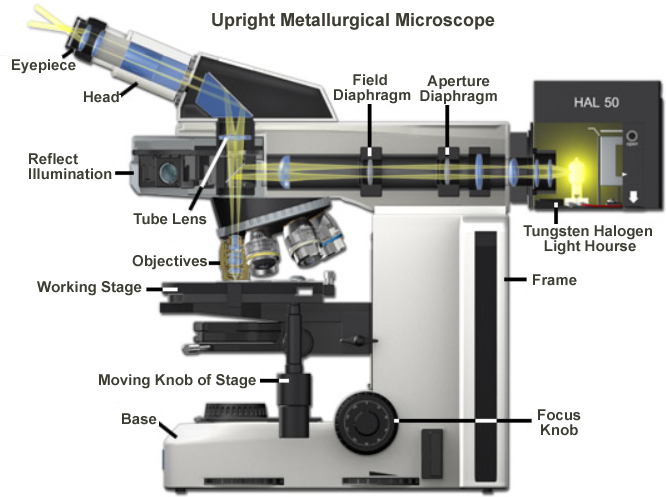

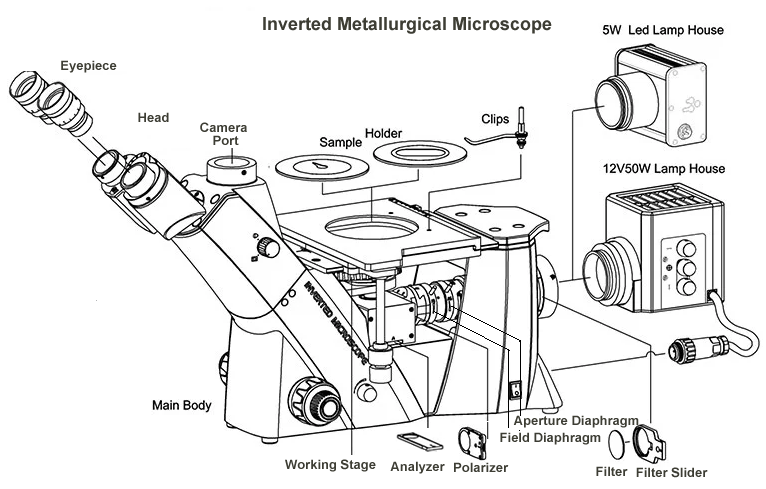

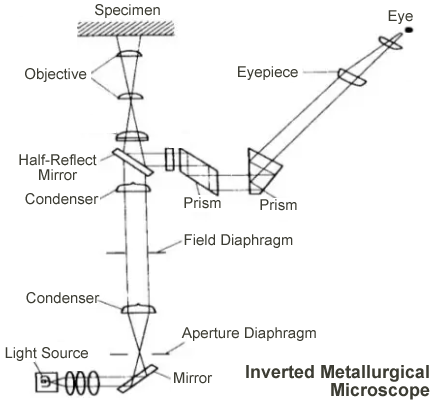

Metallurgical Microscopes are available as an Upright metallurgical microscope, or an Inverted metallurgical microscope, or on a boom stand for viewing extra large samples.

Upright metallurgical microscopes are used to view samples that will fit on the microscope stage. The structure of the upright metallurgical microscope is similar to the upright biological microscope, and the space between the objective lens and the worktable is limited, which is suitable for observing smaller samples that can be placed between the working stage and the objective lens. It can supply both transmit & reflect light source.

An inverted metallurgical microscope would be used to view larger parts, as the objective lenses are located beneath the stage and allow for placing heavy mechanical parts directly on the stage above the objectives. It usually only has reflected light source.

Features of Metallurgical Microscope

Metallurgical microscopes have several unique features that are not always found on a biological or stereo microscope:

● Polarizer & Analyzer

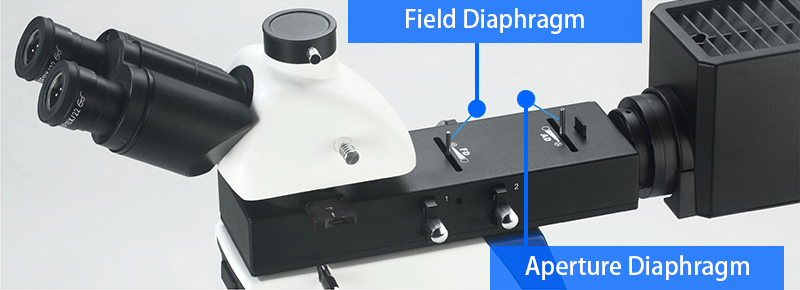

● Aperture Diaphragm & Field Diaphragm

● Differential Interference Contrast (DIC)

● High Magnification & High Resolution Objectives

● Brightfield & Darkfield

● Reflected & Transmitted Illumination

Metallurgical Microscope Light Source

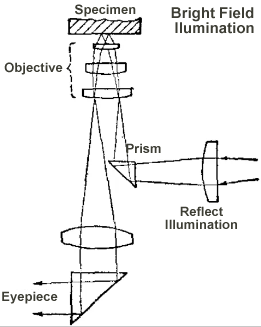

Bright Field Illumination

Bright field illumination is the main illumination method of metallographic microscope. In bright field illumination, the light from the light source enters the objective lens at an angle of 90° through the vertical illuminator, and hits the sample surface vertically (or nearly vertically). The light reflected from the sample passes through the objective lens to the eyepiece. If the sample is a polished mirror, almost all the reflected light enters the objective lens for imaging, and a bright piece can be seen in the eyepiece. If the sample is corroded after polishing and the surface of the sample is uneven, the reflected light will diffuse and rarely enter the objective lens for imaging, and what is seen in the eyepiece is a dark black image.

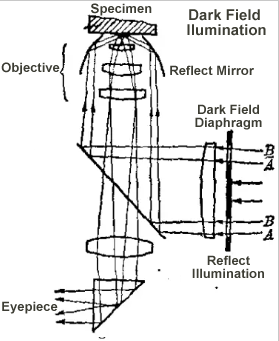

Dark Field Illumination

In special purposes such as identifying non-metallic inclusions, dark field lighting is often used. Dark-field lighting is different from bright-field lighting. The light from the light source passes through the condenser lens to form a beam of parallel light. When passing through the dark-field annular diaphragm, the central part of the parallel light is blocked to form a tube-shaped beam; then it is reflected by the plane glass. , and then reflected by the dark field curved mirror, the tubular beam is projected on the sample at a large inclination angle. It should be noted here that the tubular light beam passes around the objective lens, and the objective lens does not pass the light and thus does not play a role in concentrating light. If the sample surface is smooth and homogeneous, the projected light is reflected at large inclinations. light does not enter

Into the objective lens, what is seen in the eyepiece is a dark black. If there are unevenness on the surface of the sample, some of the reflected light will enter the objective lens to form a bright image. This is exactly the opposite of what was observed under brightfield illumination

Two Diaphragms & Filters in Metallurgical Microscope

There are two diaphragms in the metallurgical microscope illumination system:

Aperture Diaphragm

The aperture diaphragm is used to control the thickness of the incident beam, and its position is close to the light source. The aperture diaphragm can be adjusted continuously. When the aperture diaphragm shrinks, the light beam entering the objective lens becomes thinner, and the light does not pass through the edge of the objective lens group. The spherical aberration is greatly reduced, but the narrowing of the beam reduces the aperture angle of the objective lens, which will The numerical aperture actually used decreases and the resolution decreases. When the aperture diaphragm expands, the incident light beam becomes thicker, and the aperture angle of the objective lens increases, allowing the light to fill the rear lens of the objective lens. At this time, the numerical aperture can reach the rated value (that is, the N.A. value marked on the objective lens), and the resolution also increases. The improvement. However, due to the increase of spherical aberration and the increase of reflection and glare inside the lens barrel, the image quality will be reduced. Therefore, the aperture diaphragm has a great influence on the image quality, and it must be properly adjusted when using it. It cannot be too large or too small. The appropriateness should be based on the lens after the beam fills the objective lens, and it should be judged according to the clarity of the image. After changing objectives, the aperture diaphragm must be adjusted appropriately, but it should not be used to adjust the brightness of the field of view.

Field Diaphragm

In addition to the aperture diaphragm, the metallographic microscope also has a field diaphragm. Relative to the light source, its position is behind the aperture stop. Adjusting the field of view diaphragm can change the size of the microscope field of view without affecting the resolution of the objective lens. Properly adjusting the field of view diaphragm can also reduce the reflection and glare in the lens barrel, and improve the contrast and quality of the image. However, it should be noted that if the diaphragm of the field of view is too small, the observation range will be too narrow. Generally, it should be adjusted to the same size as the field of view of the eyepiece.

Filter

Color filter is an auxiliary part of the microscope, reasonable selection can improve the image quality. Color filters have the following main functions:

1) Use a yellow-green color filter with an achromatic objective lens to maximize the correction of aberrations.

2) For the apochromatic objective lens, a blue color filter can be used, because the wavelength of blue light is shorter than that of yellow-green light, it can improve the mirror resolution.

3) Decreases the intensity of the light source. In addition to the commonly used yellow-green color filter, the new microscope also has one or several gray neutral density color filters, which can be used to weaken the intensity of the incident light without changing other characteristics of the incident light. Color filters with different light transmittance can be made according to needs, and the transmittance can vary from 80% to 0.001%

How To choose a Metallurgical Microscope

Three general directions help to choose:

1, The type of sample

Are the samples sufficiently small to fit in the palm of your hand? If so, then an upright metallurgical microscope will meet your needs. If you need to observe large metal parts or other types of large samples, an inverted/column metallurgical microscope will be more suitable for you.

2, Light source

All metallurgical microscopes have reflected light source. But if you need to observe samples through which light can pass, you may need the model with transmit light source.

3, The type of objective lens

Some objectives can only be used for bright field, while others can be used for observation of dark field, DIC, ect. If you need both bright field and dark field, choose the optional BF/DF objectives.

Comments