shredders industrial play a crucial role in managing and processing waste in various sectors, including manufacturing, recycling, and waste management. These robust machines are designed to handle a wide range of materials, from paper and plastics to metal and electronic waste. The primary function of industrial shredders is to reduce the size of these materials, making them easier to handle, transport, and process further. By breaking down materials into smaller, more manageable pieces, these shredders facilitate efficient recycling and waste management processes, contributing to environmental sustainability and resource conservation.

Design and Technology in Shredding Machinery:

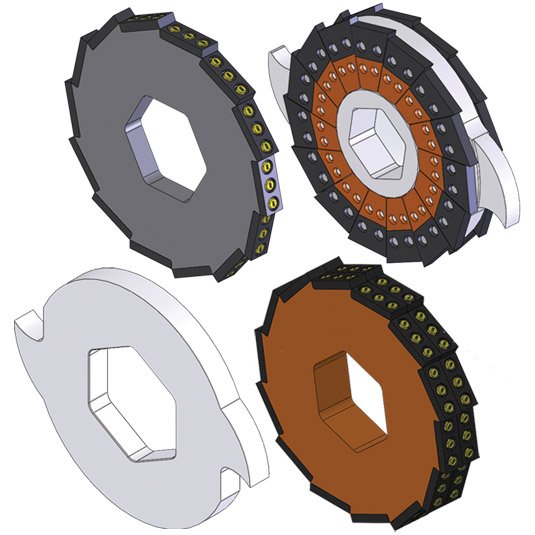

The design and technology of shredding machinery have evolved significantly over the years to meet the growing demands of industries. Modern shredders are equipped with advanced features like automatic feeding systems, energy-efficient motors, and sophisticated control panels for optimal performance. The cutting mechanisms in these machines vary, with some utilizing rotary blades while others employ single or multiple shaft systems to process different types of materials. This versatility is vital in handling the diverse range of waste products generated by various industries. The efficiency of these shredders not only lies in their capacity to process large volumes of waste but also in their ability to produce consistent, uniform output, which is essential for subsequent recycling processes.

Environmental Impact and Sustainability:

The environmental impact of industrial shredders is profoundly positive. By facilitating the reduction and recycling of waste materials, these machines play a pivotal role in reducing landfill usage and greenhouse gas emissions. Shredding machinery also contributes to the circular economy by enabling the repurposing of materials, which can be transformed into new products. This not only conserves natural resources but also reduces the energy consumption and environmental impact associated with producing new materials from scratch. Furthermore, the advancement in shredder technology has led to more energy-efficient models, further contributing to environmental sustainability.

Choosing the Right Shredder for Your Needs:

Selecting a suitable shredder for a specific industrial application requires careful consideration of several factors. These include the type and volume of material to be processed, the desired output size, and the overall efficiency of the machine. Additionally, businesses should consider the maintenance requirements and durability of the shredder, as these factors impact long-term operational costs. this organization offer a range of shredding solutions tailored to different industrial needs, ensuring that businesses can find a shredder that perfectly matches their requirements. Their expertise in the field, combined with innovative technology, makes them a go-to source for high-quality shredding machinery.

Conclusion:

In conclusion, industrial shredders and shredding machinery are indispensable in today's waste management and recycling industries. Their ability to efficiently process a wide range of materials into smaller, more manageable sizes facilitates easier handling, transportation, and further processing. This not only aids in resource conservation and environmental sustainability but also supports the circular economy. For businesses looking to invest in top-quality shredding solutions, CM Shredders cmshredders.com stands out as a leading provider, offering an array of shredders designed to meet various industrial needs. With their advanced technology and expertise, CM Shredders is well-positioned to help businesses achieve their waste management and recycling objectives.

Visit our site for more info:-

Comments