The dairy industry is one of the most demanding sectors when it comes to packaging, labeling, and product verification. From milk cartons and yogurt cups to cheese blocks and butter packs, every product must be handled with precision to ensure safety, quality, and compliance. Consumers today expect full traceability, clear labeling, and sustainable packaging, which means dairy producers need advanced packaging equipment, automated solutions, and reliable support from experienced industrial equipment suppliers.

Meeting these challenges requires more than just basic machines. Dairy producers must invest in modern label printers, industrial inkjet printers, metal detectors, and pallet wrapping machines. These technologies not only streamline operations but also maintain product integrity and enhance brand reputation. In this guide, we explore the critical equipment, processes, and best practices that every dairy business should consider.

Importance of Efficient Labeling Machines

Accurate labeling is a cornerstone of the dairy industry. Labeling machines automate the application of labels on a wide variety of dairy products such as milk cartons, yogurt containers, cheese packaging, and cream tubs. Modern label printers ensure that every product has clear and consistent labeling, which is crucial for compliance with food safety regulations.

Using automated labeling machines also reduces manual labor, prevents labeling errors, and allows high-speed production lines to operate efficiently. This is particularly important in large-scale operations, where even minor mistakes can lead to significant losses. Moreover, reliable label printers from trusted industrial supply companies ensure smooth operation, minimal downtime, and easy integration with other packaging equipment.

Custom labeling options further enhance brand identity. Custom product labels can include nutritional information, expiry dates, barcodes, QR codes, and promotional details, helping dairy producers build consumer trust and loyalty. Labels can also be tailored for eco-friendliness, bilingual requirements, or special product campaigns.

Streamlining Packaging with Case Erectors

Case erectors play a critical role in modern dairy packaging. These machines automate the formation and sealing of cartons and boxes, preparing them for product storage or shipment. By automating this step, dairy producers can significantly reduce labor costs, improve throughput, and maintain uniform packaging quality.

In addition to efficiency, case erectors contribute to workplace safety. Heavy boxes no longer need to be manually handled, reducing the risk of injuries. These machines are compatible with various packaging types, from standard cardboard boxes to more specialized dairy cartons. A well-integrated case erector system works seamlessly with other packaging equipment such as pallet wrappers, automatic wrappers, and industrial inkjet printers, creating a streamlined production workflow.

Enhancing Product Protection with Pallet Wrapping Machines

Once dairy products are packed into boxes, securing them for storage and transport is essential. Pallet wrapping machines, also known as stretch wrap equipment, tightly wrap products on pallets using stretch film, protecting them from movement, contamination, and damage.

Proper use of pallet wrapping machines ensures products arrive in perfect condition at retailers or distributors. Additionally, automated pallet wrappers improve warehouse space utilization, simplify loading and unloading, and reduce manual labor. By investing in high-quality stretch film wrapping machines, dairy producers can protect their products, maintain efficiency, and reduce overall packaging waste.

Boosting Efficiency with Automatic Wrappers

Automatic wrappers are indispensable for dairy producers who want to speed up production while maintaining consistent quality. These machines wrap individual products, such as cheese blocks, butter packs, and other dairy items, in materials like plastic film or paper.

Using an automatic wrapper reduces material waste, ensures uniformity across products, and allows producers to maintain high production speeds. Integration with other packaging equipment, like labeling machines and case erectors, creates a seamless automated production line, enhancing efficiency and reducing the chances of human error.

Sourcing High-Quality Packaging Supplies

Reliable packaging supplies are just as important as the machinery used to process dairy products. A reputable packaging supply store provides a wide range of essential items such as custom product labels, ribbons, sealing materials, stretch film, and other packaging materials.

Dairy producers who partner with trusted suppliers benefit from high-quality products that meet regulatory standards and withstand rigorous production conditions. Quality packaging supplies enhance product durability, improve consumer perception, and reduce waste caused by damaged packaging.

Industrial Inkjet Printers for Coding and Marking

Accurate product marking is vital for dairy traceability. Industrial inkjet printers allow producers to print batch numbers, expiry dates, barcodes, and other vital information directly on packaging. High-resolution printing ensures that all markings are legible and compliant with regulatory requirements.

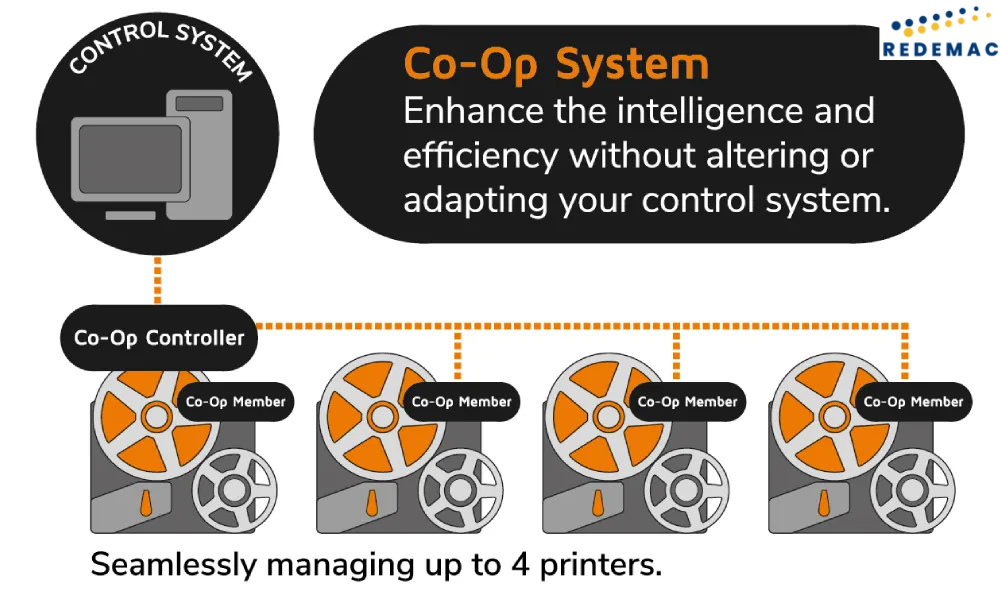

Advanced industrial inkjet printer features, such as touch screens, remote diagnostics, and compatibility with multiple surfaces, make them highly suitable for modern dairy production lines. By integrating these printers with other packaging equipment, dairy producers can achieve seamless operations and reduce manual intervention.

Ensuring Product Safety with Metal Detectors

Consumer safety is paramount in the dairy industry. Metal detectors or metal locators are essential tools to identify and remove any metal contamination during production. These devices are integrated into production lines, scanning products as they pass to prevent contaminated items from reaching consumers.

Regular maintenance and calibration of metal detectors ensure reliability and help maintain product integrity. Incorporating these systems into your dairy production workflow also safeguards your brand reputation and meets food safety compliance standards.

Integrating Packaging Equipment for Smooth Operations

The best results in dairy packaging come from integrating all equipment into a cohesive system. Synchronizing labeling machines, case erectors, pallet wrappers, and automatic wrappers reduces errors, decreases manual labor, and improves production throughput.

Seamless integration also allows better tracking of production data, including packaging speed, label accuracy, and product handling. This data can be used to optimize production, improve sustainability, and reduce costs over time.

Custom Product Labels for Brand Differentiation

In a competitive market, custom product labels can make a difference. Dairy producers can offer personalized labels, eco-friendly materials, bilingual options, and highlight certifications like organic or local sourcing. Custom labels not only meet consumer preferences but also enhance brand visibility and loyalty.

Partnering with Industrial Equipment Suppliers

Choosing a trusted industrial equipment supplier ensures access to advanced packaging equipment, industrial automation solutions, and support services. Suppliers provide demos, on-site training, spare parts, and maintenance support.

Using label printers such as Zebra Technologies label printer or Toshiba printer along with industrial inkjet printers and packaging machinery from a reputable supplier ensures seamless operations, high productivity, and compliance with industry standards.

Final Thoughts

The dairy industry must meet high standards for efficiency, product integrity, and compliance. Investing in packaging equipment, industrial inkjet printers, metal detectors, labeling machines, and other automation solutions enhances productivity and ensures product quality.

Working with reliable industrial supply companies and a trusted packaging supply store helps integrate processes smoothly while reducing downtime and waste. Automation not only streamlines operations but also contributes to sustainability by optimizing resource usage.

For expert guidance on upgrading your dairy packaging operations, contact our team at Redemac.

FAQs

1. What is the role of labeling machines in the dairy industry?

Labeling machines ensure consistent, accurate labeling, which is essential for compliance and consumer information.

2. How do case erectors help dairy packaging?

Case erectors automate box forming and sealing, improving efficiency and reducing labor costs.

3. Why are pallet wrapping machines important?

Pallet wrapping machines secure products during transport, preventing damage and ensuring optimal delivery.

4. How do automatic wrappers benefit packaging?

Automatic wrappers improve production speed, reduce material waste, and maintain packaging quality.

5. How do custom product labels enhance brand appeal?

Custom product labels cater to consumer preferences, highlight certifications, and boost brand recognition.

.png)

Comments