Stainless steel wire mesh screens are crucial materials used in a variety of applications, ranging from industrial processes to architectural designs. Among the different types of stainless steel mesh, 304 and 316 stainless steel are the most commonly used. While both materials have similar characteristics, they differ in several key aspects, particularly when it comes to corrosion resistance, strength, and cost. This article explores the differences between 304 and 316 stainless steel wire mesh screens, helping you understand their unique features and how to choose the right one for your needs.

What is Stainless Steel Wire Mesh Screen?

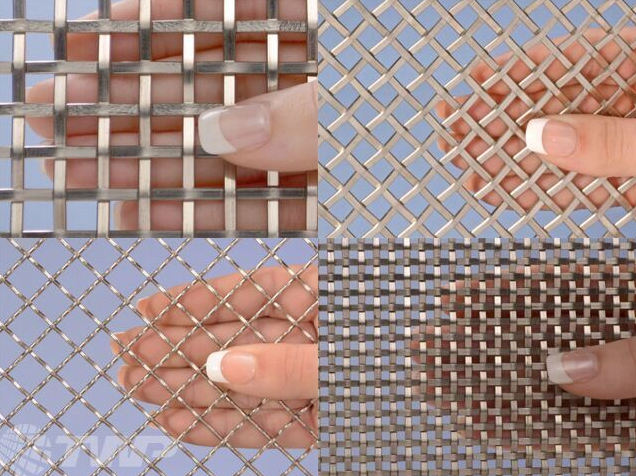

A stainless steel wire mesh screen is a versatile material made from woven stainless steel wire. The mesh comes in different grades and is used for various purposes, such as filtration, safety barriers, screens, and decorative elements. The wire mesh is designed to resist rust, corrosion, and staining, which makes it ideal for use in harsh environments, whether in industrial plants or outdoor settings. The two most popular grades of stainless steel wire mesh are 304 and 316, each offering its own set of advantages and characteristics.

Key Characteristics of 304 Stainless Steel Wire Mesh Screen

304 stainless steel is the most commonly used grade of stainless steel wire mesh. It is known for its excellent balance of strength, durability, and cost-effectiveness.

1. Corrosion Resistance

304 stainless steel is highly resistant to corrosion from a variety of chemicals and atmospheric conditions. However, its resistance to corrosion is limited when exposed to highly corrosive substances, such as chlorides and marine environments.

2. Durability

304 stainless steel wire mesh screens offer good mechanical properties, including strength and flexibility, making them ideal for general industrial applications. They are resistant to oxidation and can withstand temperatures up to approximately 870°C (1600°F) without significant degradation.

3. Applications of 304 Stainless Steel Wire Mesh

304 stainless steel mesh is commonly used in the following applications:

· Filtration: For filtering food, beverages, or chemicals.

· Architectural Mesh: Used in facades and decorative elements.

· Industrial Applications: For screens, safety guards, and enclosures.

· Food Processing: Due to its non-reactive nature.

4. Cost-Effectiveness

304 stainless steel is more affordable compared to 316 stainless steel, making it a popular choice for applications where extreme corrosion resistance is not a primary concern.

Key Characteristics of 316 Stainless Steel Wire Mesh Screen

316 stainless steel, often referred to as marine-grade stainless steel, is the next step up in terms of corrosion resistance and durability. It is particularly suited for harsher environments that demand superior protection against corrosion.

1. Superior Corrosion Resistance

The defining feature of 316 stainless steel is its resistance to corrosion, particularly in chloride environments. The addition of molybdenum (2-3%) in 316 stainless steel provides enhanced resistance to pitting and crevice corrosion, making it ideal for use in marine environments, chemical processing plants, and saltwater exposure.

2. Enhanced Durability

316 stainless steel wire mesh screens are stronger and more durable than 304 stainless steel, especially in corrosive environments. It can withstand high temperatures and is highly resistant to acidic and alkaline solutions.

3. Applications of 316 Stainless Steel Wire Mesh

316 stainless steel is typically used in environments where enhanced corrosion resistance is required. Some key applications include:

· Marine Environments: For use in boat fittings, seawater filtration, and coastal architectural designs.

· Chemical Processing: To filter aggressive chemicals or caustic substances.

· Medical and Pharmaceutical Industries: For use in sterile environments where contamination risks are high.

· Food and Beverage: In environments where highly acidic substances or high levels of chloride are present.

4. Higher Cost

Due to the addition of molybdenum and other alloying elements, 316 stainless steel wire mesh is more expensive than 304 stainless steel. However, its long-term durability and superior performance make it worth the investment in demanding applications.

Comparing 304 and 316 Stainless Steel Wire Mesh Screens

1. Corrosion Resistance

· 304 Stainless Steel: Resistant to most environmental factors but not suitable for environments with high chloride content, such as coastal areas or marine environments.

· 316 Stainless Steel: Exceptional resistance to corrosion, particularly in saltwater and highly acidic conditions.

2. Strength and Durability

· 304 Stainless Steel: Offers adequate strength and flexibility for general applications.

· 316 Stainless Steel: More robust and durable, particularly for heavy-duty applications in harsh environments.

3. Cost Considerations

· 304 Stainless Steel: More affordable and ideal for general-purpose use.

· 316 Stainless Steel: Higher cost but offers superior performance in corrosive and extreme conditions.

4. Applications

· 304 Stainless Steel: Suitable for general industrial, architectural, and filtration applications.

· 316 Stainless Steel: Best suited for marine, pharmaceutical, food processing, and chemical industries.

When to Use 304 Stainless Steel Wire Mesh Screen

304 stainless steel wire mesh is a great option when corrosion resistance is not a critical factor. It is ideal for:

· General-purpose filtration in non-corrosive environments.

· Construction and architectural applications where aesthetics and cost are important.

· Agricultural and food processing environments where exposure to harsh chemicals is minimal.

When to Use 316 Stainless Steel Wire Mesh Screen

316 stainless steel wire mesh is the preferred choice when the material will be exposed to harsh or corrosive conditions, such as:

· Marine environments where the mesh is constantly exposed to saltwater.

· Chemical processing where the mesh will be in contact with acidic or alkaline substances.

· Pharmaceutical and medical industries where hygiene and resistance to corrosion are essential.

· Food and beverage industries that deal with high-chloride or acidic substances.

Conclusion

Both 304 and 316 stainless steel wire mesh screens offer unique benefits depending on your specific needs. If you are working in a general industrial environment or require a cost-effective solution, 304 stainless steel is likely your best option. However, for applications where enhanced corrosion resistance and durability are critical, particularly in marine or chemical industries, 316 stainless steel is the superior choice.

At Huijin Metal Meshes, we offer a wide variety of stainless steel wire mesh screens in both 304 and 316 grades to suit various industrial, architectural, and filtration needs. Whether you're looking for strength, durability, or resistance to harsh environments, we provide the perfect solution to meet your requirements.

Comments