In the demanding world of mining and mineral processing, the ability to handle abrasive and viscous slurries efficiently is crucial for ensuring productivity and minimizing downtime. Pumps used in such environments must be designed to withstand extreme conditions while maintaining consistent performance. This is where vertical slurry pump and froth pumps play a vital role. Brands like CNSME PUMP are leading the way in delivering reliable solutions tailored for these harsh industrial settings.

Understanding Vertical Slurry Pumps

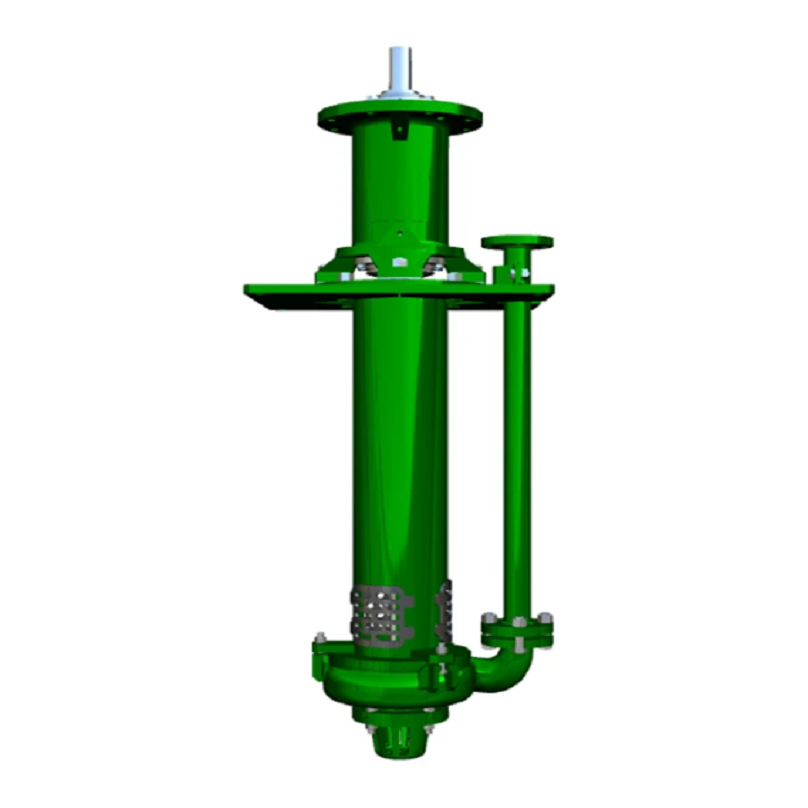

A vertical slurry pump is a type of centrifugal pump designed for pumping abrasive slurries in vertical configurations. Unlike horizontal pumps, these are submerged partially in the sump or pit, making them ideal for applications where floor space is limited or where the slurry is collected below ground level.

Vertical slurry pumps are commonly used in:

- Mining operations

- Mineral processing plants

- Steel and power plants

- Coal washing

- Chemical processing

Key benefits of vertical slurry pumps include:

- Space efficiency: The vertical design allows for installation in tight spaces or deep pits.

- Corrosion and abrasion resistance: Made with durable materials like high-chrome alloys to withstand wear.

- Easy maintenance: The pump’s design allows for quick inspection and replacement of parts.

CNSME PUMP manufactures a wide range of vertical slurry pumps built to meet the challenges of mining and slurry handling. Their designs focus on durability, performance, and minimal downtime — crucial for any industrial operation.

What is a Froth Pump?

A froth pump is specially designed to handle frothy slurries — mixtures of air, water, and solids that are common in flotation processes in mineral processing plants. Froth can be difficult to pump using standard slurry pumps because air tends to block the impeller, reducing efficiency and flow rate.

Froth pumps from CNSME PUMP are designed with enlarged inlet diameters and open impellers that allow air to pass through more easily, reducing the risk of air lock and maintaining consistent pumping even with high froth content.

Typical applications of froth pumps include:

- Flotation cell discharge in copper, gold, and phosphate mines

- Coal flotation

- Frothy waste management in chemical processing

Why Choose CNSME PUMP?

CNSME PUMP has built a strong reputation in the global pump industry by offering high-quality slurry and froth pumps backed by decades of engineering expertise. Here’s why CNSME is a trusted choice:

- Durability and performance: Their pumps are engineered to withstand the toughest abrasive and corrosive environments.

- Customization options: CNSME PUMP provides tailor-made solutions to fit specific operational needs.

- After-sales support: With a focus on customer service, they offer comprehensive support, spare parts, and maintenance assistance.

- Global reach: CNSME’s products are trusted by mining and processing operations around the world.

Their vertical slurry pumps and froth pumps are specifically designed for long service life and ease of maintenance, two essential factors in reducing operational costs.

Best Practices for Slurry and Froth Pump Maintenance

To get the most out of your CNSME PUMP equipment, regular maintenance and monitoring are essential. Here are some best practices:

- Monitor wear parts: Regularly inspect the impeller, liner, and shaft sleeve for signs of wear.

- Check alignment: Ensure that the pump and motor alignment is within tolerances to prevent bearing damage.

- Seal system care: Use appropriate sealing systems and monitor them to prevent leaks.

- Lubrication: Keep bearings well-lubricated according to the manufacturer’s specifications.

- Operate within design limits: Avoid overloading the pump or running it dry, as this can cause damage and reduce lifespan.

Conclusion

Efficient slurry handling is the backbone of successful mining and mineral processing operations. Both vertical slurry pumps and froth pumps serve essential roles in managing different types of abrasive and frothy slurries. When it comes to performance, reliability, and long-term value, CNSME PUMP stands out as a trusted provider of high-quality pumping solutions.

Whether you are dealing with deep sumps full of heavy slurry or flotation processes with challenging frothy mixtures, CNSME offers robust, well-engineered pumps that help keep your operations running smoothly. Investing in the right pump technology not only ensures operational efficiency but also significantly reduces downtime and maintenance costs.

If you’re in the market for a vertical slurry pump or froth pump, CNSME PUMP should be your first stop for durable, dependable, and efficient pumping solutions.

Comments