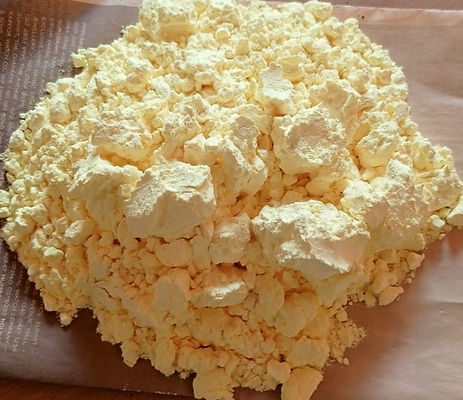

Sulphur powder is a commonly used chemical in various industries, including agriculture, chemical manufacturing, rubber manufacturing, pharmaceuticals, and food. It is available in different mesh sizes, with 200 mesh and 325 mesh being two common options. In this article, we will explore the difference between sulphur powder 200 mesh and 325 mesh, and their applications in different industries, with a focus on the rubber industry. We’ll also take a closer look at how Vasmate Sulphur Industry, a leading supplier of high-quality sulphur powder, can help meet the needs of various industries.

Mesh Size:

What Does it Mean? Mesh size refers to the number of openings in a square inch of a screen through which the particles can pass. The higher the mesh number, the finer the particle size. Sulphur powder 200 mesh means that the powder contains particles that are smaller than 74 microns (0.074 mm) in size, whereas sulphur powder 325 mesh contains particles that are smaller than 44 microns (0.044 mm) in size.

Applications of Sulphur:

Powder Sulphur has a wide range of applications in various industries. Here are some common uses:

- Agriculture: Sulphur powder is used as a fungicide and pesticide in the agriculture industry to control various plant diseases and pests.

- Chemical Manufacturing: Sulphur powder is used as a raw material in the production of sulphuric acid, sulphur dioxide, dyes and pigment, and other chemicals.

- Rubber Manufacturing: Sulphur powder is used as a vulcanizing agent in the rubber industry to improve the strength, durability, and elasticity of rubber products.

- Pharmaceutical Industry: Sulphur powder is used in the production of certain drugs and medications, such as sulfa antibiotics and antifungal agents.

- Food Industry: Sulphur powder is used as a food preservative in the form of sulfites to prevent bacterial and fungal growth in food products.

Sulphur Powder in the Rubber Industry:

In the rubber industry, sulfur powder is used as a vulcanizing agent, which is added to rubber compounds to improve their physical properties. The vulcanization process involves the reaction between the sulphur and the rubber, resulting in cross-linking of the rubber molecules and the formation of a three-dimensional network structure. This network structure improves the strength, durability, and elasticity of the rubber product.

In the rubber industry, sulphur powder with a finer particle size, such as 325 mesh, is preferred over coarser sulfur powder with a lower mesh size, such as 200 mesh. The finer sulphur powder with a higher mesh size has a larger surface area, which enables it to disperse more easily and uniformly throughout the rubber compound. This results in better mixing of the sulphur powder with the rubber, which is important for achieving consistent and uniform vulcanization. In addition, finer sulphur powder with a higher mesh size can also improve the reactivity and effectiveness of the vulcanizing agent, resulting in better physical properties of the rubber product, such as increased strength, durability, and elasticity.

In conclusion, Vasmate Sulphur Industries is a leading supplier of high-quality sulphur powder, offering tailored solutions for various industries. Their sulphur powder comes in different mesh sizes, including 200 mesh and 325 mesh, to meet the specific requirements of different applications. With advanced production facilities and rigorous quality control measures, Vasmate Sulphur Industry ensures that its sulphur powder is versatile and suitable for use in diverse industries. For the rubber industry, 325 mesh sulphur powder is preferred due to its better dispersion and mixing properties. By understanding the differences between these mesh sizes and their respective applications, businesses can make informed decisions about which sulphur powder to use for their particular needs.

For more info: sulphur suppliers from India

Comments