In today’s fast-paced manufacturing world, precision, speed, and automation are crucial. The demand for durable fasteners in automotive, construction, and industrial applications has driven innovation in machinery such as the Thread Rolling Machine Ludhiana, Fully Automatic Thread Rolling Machine in India, Header Machine Manufacturer in India, and Bolt Making Machine Manufacturers In India. These advanced machines are transforming how industries produce bolts, screws, and fasteners—enhancing efficiency, accuracy, and cost-effectiveness.

The Importance of Thread Rolling Technology

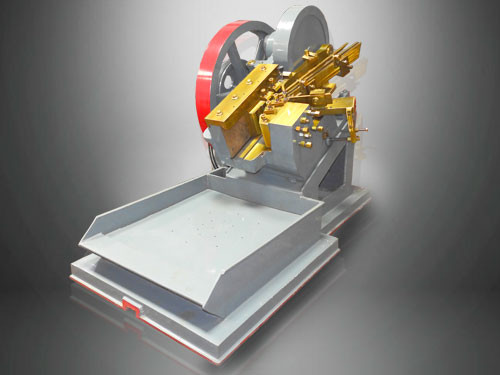

Thread rolling is a cold-forming process that displaces metal to form threads rather than cutting them, resulting in stronger and more accurate fasteners. The Thread Rolling Machine Ludhiana has gained immense popularity due to its reliability, compact design, and precision. Ludhiana, often referred to as the industrial hub of North India, is home to many manufacturers producing high-quality thread rolling machines catering to both domestic and international markets.

These machines are essential in producing flawless threads on bolts and screws, ensuring consistency and longevity. With the growing demand for threaded components, businesses increasingly rely on automated solutions to meet bulk requirements with minimal human intervention.

Rise of Fully Automatic Thread Rolling Machines in India

The evolution from manual to Fully Automatic Thread Rolling Machine in India has revolutionized the manufacturing landscape. These machines are equipped with advanced PLC control systems, auto-loading/unloading mechanisms, and high-speed operation capabilities. Manufacturers in India have developed fully automatic models that significantly reduce labor costs, improve productivity, and enhance product quality.

One of the major benefits of these machines is their ability to work continuously with minimal maintenance.

Their precision-controlled systems ensure perfect thread geometry, making them ideal for industries where high accuracy is critical. As industries lean towards smart manufacturing, fully automatic thread rolling machines are becoming a preferred choice for long-term investment.

The Role of Header Machine Manufacturers in India

A crucial component of the bolt-making process is the heading operation, which shapes the head of the bolt. Header Machine Manufacturer in India play a pivotal role in this domain. Indian manufacturers offer a wide range of header machines, including single die, double die, and multi-station headers, designed to suit various bolt sizes and production requirements.

These machines are built with sturdy construction, ergonomic designs, and high output capacity, making them suitable for both small-scale and large-scale industries. Indian manufacturers are known for integrating advanced technologies like servo motors, digital touch screens, and automatic error detection systems in their header machines, ensuring minimal downtime and maximum efficiency.

Bolt Making Machine Manufacturers in India: Precision and Performance

The fastener industry in India is thriving, thanks to the contributions of Bolt Making Machine Manufacturers In India. These manufacturers supply a comprehensive range of machines, including thread rolling, heading, pointing, and trimming machines. Their integrated bolt-making solutions cater to various sectors such as automotive, infrastructure, electrical, and heavy engineering.

Indian bolt-making machines are recognized globally for their durability, ease of operation, and cost efficiency. They can produce bolts in a wide range of sizes and specifications, using materials like stainless steel, carbon steel, and alloy steel. With continuous R&D and adherence to international standards, Indian manufacturers are exporting machines to countries across Asia, Africa, Europe, and the Americas.

Future of Fastener Manufacturing in India

India’s manufacturing sector is poised for exponential growth, and the fastener machinery segment is no exception. The increased focus on infrastructure development, Make in India initiatives, and global exports has led to greater demand for high-quality machinery like the Thread Rolling Machine Ludhiana, Fully Automatic Thread Rolling Machine in India, Header Machine Manufacturer in India, and Bolt Making Machine Manufacturers In India.

Innovations such as AI-powered control systems, IoT-enabled monitoring, and energy-efficient motors are paving the way for the next generation of fastener manufacturing. As companies continue to modernize their facilities, investing in high-performance and automated machinery will be key to staying competitive in both domestic and international markets.

Conclusion

The industrial machinery sector in India, particularly in fastener production, is undergoing a transformative shift. With the rise of automation, smart manufacturing, and export-oriented growth, machines like the Thread Rolling Machine Ludhiana and those offered by leading Bolt Making Machine Manufacturers In India are setting new benchmarks in quality and efficiency. For businesses aiming to scale production and improve profitability, investing in these cutting-edge machines is a strategic move toward a more robust and technologically advanced future.

Comments