The electronics industry has become one of the most dynamic and fast-evolving sectors worldwide, and at the heart of this industry lies the printed circuit board (PCB). From smartphones and medical equipment to automobiles and industrial machinery, PCBs form the backbone of all modern electronic devices. As demand for high-quality, reliable, and cost-effective PCBs continues to grow, PCB assembly manufacturers in India are emerging as global leaders. With advanced technologies, skilled talent, and robust infrastructure, PCB manufacturing in India is scaling new heights, offering world-class solutions to both domestic and international markets.

At MechPlaza, we recognize the vital role that PCB technology plays in powering today’s innovations. This blog explores the growing prominence of Indian PCB manufacturers, their capabilities, and why India is quickly becoming a hub for PCB production and assembly.

The Growing Importance of PCB Manufacturing in India

PCBs are the foundation upon which electronic components are mounted and interconnected. They ensure electrical connectivity, support mechanical stability, and enable compact and efficient device designs. As industries such as automotive, telecommunications, aerospace, healthcare, and consumer electronics expand, the need for advanced PCBs has skyrocketed.

India has emerged as a preferred destination for PCB manufacturing for several reasons:

- Cost-Effectiveness: Competitive labor costs combined with advanced automation allow Indian manufacturers to offer affordable solutions without compromising quality.

- Skilled Workforce: Engineers and technicians in India possess strong expertise in electronics design and assembly.

- Government Support: Initiatives like "Make in India" and Production-Linked Incentive (PLI) schemes encourage local manufacturing and attract global investments.

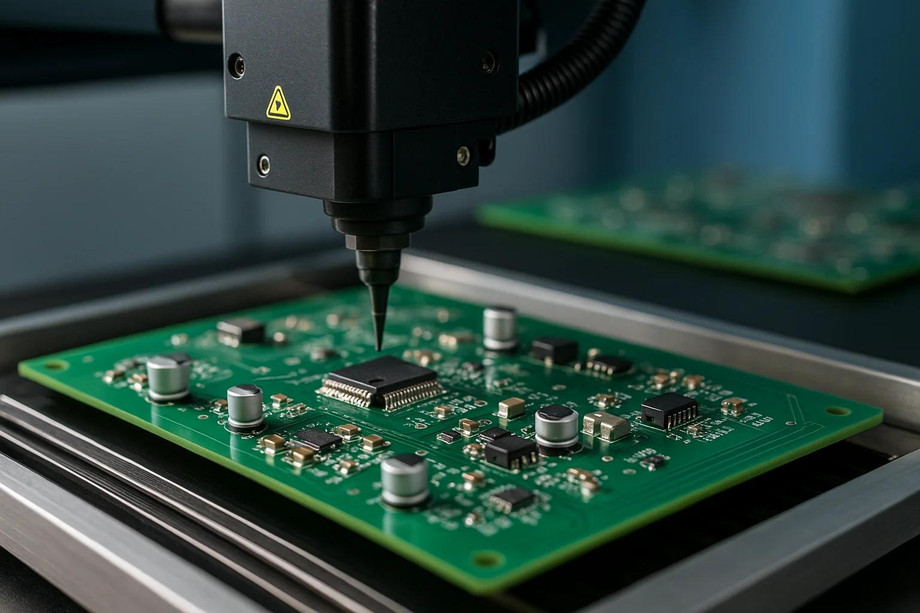

- Technological Upgradation: Many Indian manufacturers are investing in automation, AI-driven assembly lines, and cutting-edge testing equipment.

Who are PCB Assembly Manufacturers in India?

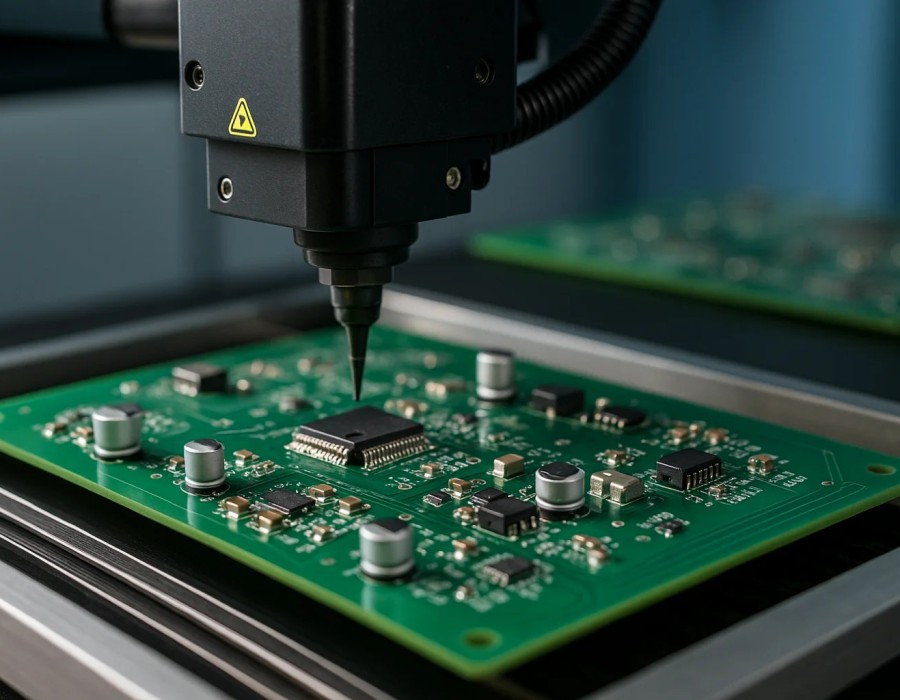

PCB assembly manufacturers in India specialize in producing finished PCBs by assembling electronic components onto the circuit boards. Their services go beyond simple manufacturing; they include:

- Prototype Development – Creating quick-turn prototypes to validate designs before mass production.

- Surface Mount Technology (SMT) Assembly – Attaching components directly onto the PCB surface with high precision.

- Through-Hole Assembly – Inserting and soldering components through drilled holes for strength and durability.

- Mixed Technology Assembly – Combining SMT and through-hole for complex designs.

- Functional Testing – Ensuring every assembled PCB works flawlessly under real-world conditions.

These manufacturers cater to industries requiring custom PCBs for everything from simple consumer gadgets to highly specialized aerospace and defense systems.

Advantages of Choosing PCB Assembly Manufacturers in India

Selecting PCB assembly manufacturers in India offers several advantages for businesses worldwide:

- High-Quality Standards

- Indian manufacturers adhere to international certifications such as ISO, IPC, and RoHS compliance. This ensures top-notch quality and safety across all boards.

- Cost Competitiveness

- Compared to Western markets, Indian PCB manufacturers provide the same quality at significantly lower costs, making them attractive outsourcing partners.

- Customization and Flexibility

- From single-layer to multi-layer PCBs, Indian manufacturers can handle customized designs and small-to-large volume orders.

- Innovation and R&D

- Many manufacturers invest in research and development, offering innovative solutions like flexible PCBs, rigid-flex PCBs, and HDI (High-Density Interconnect) boards.

- Global Supply Chain Integration

- With efficient logistics and partnerships, Indian manufacturers can export to Europe, the U.S., and Asia with quick turnaround times.

Current Trends in PCB Manufacturing in India

The demand for PCBs is driving rapid technological advancements. Some key trends shaping PCB manufacturing in India include:

- Miniaturization of Devices – As electronics get smaller and more powerful, manufacturers are focusing on compact, multi-layer, and high-density PCBs.

- Green Manufacturing – Increasing emphasis on eco-friendly practices, including lead-free soldering and RoHS-compliant materials.

- IoT and Wearable Devices – Growing adoption of smart devices has created demand for flexible and lightweight PCBs.

- Automation and AI – Many PCB assembly units now use robotics and AI to improve precision, reduce defects, and increase production efficiency.

- Defense and Aerospace Growth – India’s investment in defense technology has boosted the need for highly reliable, rugged PCBs.

Challenges Faced by PCB Manufacturers in India

Despite the impressive growth, the PCB sector in India also faces challenges:

- Dependence on Imports – A significant portion of raw materials such as laminates and copper foil is still imported.

- High Initial Capital Investment – Setting up PCB fabrication plants requires substantial investment in machinery and cleanroom environments.

- Global Competition – Countries like China and Taiwan dominate the PCB market, offering stiff competition.

However, with government incentives and a growing domestic market, India is steadily overcoming these hurdles.

The Role of MechPlaza in Supporting PCB Innovation

At MechPlaza, we work closely with industry leaders, engineers, and innovators who rely on PCB assembly manufacturers in India for their projects. Whether you are a startup developing IoT devices or an established enterprise in automotive electronics, our platform connects you with reliable partners in PCB manufacturing in India.

We help businesses identify the best manufacturers who align with their requirements for quality, volume, and technology. By bridging the gap between manufacturers and clients, MechPlaza empowers industries to innovate faster and more efficiently.

Why the Future of PCB Manufacturing in India is Bright

The PCB industry in India is projected to grow exponentially in the coming years, driven by:

- Rising domestic consumption of electronics.

- Expansion of 5G networks and telecommunications.

- Demand from electric vehicles and renewable energy systems.

- Growing exports due to global supply chain diversification.

With its strong engineering base, cost advantages, and government support, India is poised to become one of the world’s leading PCB hubs.

Final Thoughts

The electronics revolution is built on a foundation of reliable PCBs. As demand continues to rise, PCB assembly manufacturers in India are positioning themselves as global leaders by offering innovative, cost-effective, and high-quality solutions.

At MechPlaza, we celebrate and support this growth by connecting businesses with the right manufacturers, driving progress across industries. Whether you’re looking for prototypes, large-scale production, or advanced PCB solutions, the future of PCB manufacturing in India has never been more promising.

With innovation at its core, India is not just participating in the global electronics industry—it is leading it forward.

Comments