High-pressure pipelines demand durable, reliable connections that can handle extreme operating conditions. Whether you are building a new system or upgrading existing infrastructure, selecting the right coupling and fitting is a decision that impacts performance, safety, and operational efficiency. This expanded guide takes a deep dive into Victaulic couplings and fittings, their advantages, applications, and buying considerations.

Why Coupling and Fitting Selection Matters?

Pipelines transporting liquids or gases at high pressures face continuous mechanical stress, especially in demanding applications like drilling mud pumps. Using the wrong connection type increases the risk of leaks, costly downtime, and even catastrophic failures. High-quality couplings and fittings, along with reliable components such as a Victaulic butterfly valve, help ensure a secure seal, boost safety, and reduce the need for frequent repairs.

In high-stakes industries, this level of reliability can mean the difference between smooth operations and costly breakdowns. Proper component selection also supports compliance with industry standards and environmental safety regulations. Even a minor leak in a high-pressure system can cause environmental contamination or safety hazards, making the choice of connection components—such as the right Victaulic butterfly valve—a crucial part of responsible pipeline management.

Understanding Victaulic Couplings

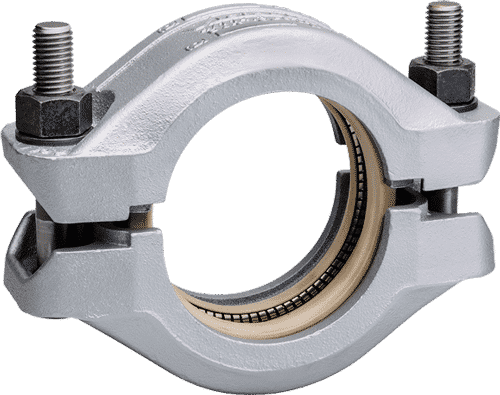

Victaulic couplings are mechanical pipe-joining systems designed to eliminate welding and flanging. Each coupling uses a housing, a gasket, and bolts to form a tight, flexible seal. This design allows for slight pipe movement, vibration absorption, and misalignment correction—critical factors for systems that operate under constant load.

Key advantages include:

- Rapid installation compared to welded or flanged connections.

- Ability to handle misalignment without compromising the seal.

- Lower installation and labor costs over time.

- Flexibility to accommodate thermal expansion and contraction.

- Reduction in specialized labor requirements.

How They Perform in High-Pressure Pipelines

In high-pressure applications, couplings must endure both internal forces from the fluid and external mechanical stresses. Victaulic couplings use precisely machined grooves to lock onto pipe ends, with the gasket providing a continuous seal that adapts to thermal changes and vibration. This resilience is especially valuable in industries where pipeline integrity is non-negotiable.

In addition, their modular nature allows for easier expansion or modification of pipeline systems without requiring complete system shutdowns or costly welding work.

Exploring Types of Victaulic Fittings

Fittings are essential for shaping, branching, and terminating pipeline systems. Victaulic fittings come in forms such as elbows, tees, reducers, and caps. They are built for strength, efficiency, and compatibility with couplings. Materials vary from ductile iron and stainless steel to specialty alloys for corrosive or high-temperature environments, ensuring performance in diverse conditions.

Special fittings for abrasive environments, such as mining slurry lines or drilling mud pumps, are engineered to resist wear and maintain structural integrity under harsh conditions.

The Role of Specialty Valves

Specialty valves control, direct, and isolate flow within a pipeline. The Victaulic butterfly valve is a standout choice for quick shutoff and throttling, known for its easy integration with couplings. This combination simplifies assembly, reduces the need for extra flanges, and cuts overall system weight. In high-pressure systems, the quick actuation of butterfly valves also enhances safety during emergency shutoffs.

Factors to Consider Before Purchasing

When selecting Victaulic couplings and fittings, evaluate:

- Operating Pressure – The product’s pressure rating should exceed system demands.

- Pipe Compatibility – Ensure perfect size and material matches for a tight seal.

- Temperature Range – Choose gaskets designed for your operational temperatures.

- Chemical Compatibility – Select materials resistant to corrosion and degradation.

- Maintenance Access – Opt for designs that make inspections and replacements easy.

- Environmental Conditions – Consider exposure to weather, UV light, or corrosive atmospheres.

Installation Best Practices

Start by cleaning and inspecting pipe ends for damage. Position the gasket correctly and follow manufacturer torque specifications for bolts. Over-tightening can distort the gasket, while under-tightening may result in leaks. Once installed, conduct a pressure test to confirm the connection’s integrity.

Training installation crews on these best practices ensures consistency and reduces the risk of premature failures.

Maintenance Guidelines

Maintenance should include routine visual inspections for gasket wear, bolt loosening, or signs of corrosion. Timely part replacement helps maintain efficiency and prevents small issues from escalating. Keeping spare gaskets and bolts on hand can speed up repairs and minimize downtime.

In industries with continuous operations, predictive maintenance schedules using condition monitoring tools can further extend the lifespan of Victaulic components.

Applications Across Industries

Victaulic couplings and fittings are used in sectors where reliability is paramount:

- Oil and Gas – Safe, dependable performance in crude, gas, and refined product transport.

- Mining – Proven durability in abrasive slurry systems and drilling mud pumps.

- Water Treatment – Secure high-pressure clean water delivery.

- HVAC – Efficient connections in large heating and cooling networks.

- Marine – Corrosion-resistant designs for seawater systems.

Cost-Benefit Analysis

While the upfront cost of Victaulic components can be higher than some alternatives, the long-term savings in labor, downtime, and maintenance are substantial. Their reusability also contributes to overall cost efficiency, as parts can be easily disassembled and reused without specialized tools.

When factoring in safety improvements, reduced installation time, and operational flexibility, the return on investment becomes even more significant.

Future Trends in Coupling Technology

Advances in gasket materials, corrosion-resistant alloys, and eco-friendly manufacturing processes are shaping the next generation of couplings. Expect even faster installation systems and designs tailored to withstand more extreme conditions.

Integration with digital monitoring tools is also emerging, allowing real-time detection of leaks or pressure fluctuations.

Common Mistakes to Avoid

New buyers sometimes choose couplings based solely on price, overlooking compatibility and pressure ratings. Others skip proper torqueing during installation, leading to premature leaks. Failing to match gasket material to the operating environment is another common oversight.

Avoiding these mistakes ensures your investment delivers its full lifespan.

Conclusion

Choosing the right couplings and fittings is an investment in system safety, efficiency, and reliability. Whether integrated into drilling mud pumps or paired with a Victaulic butterfly valve, these components ensure smooth, long-term pipeline operation. By understanding their capabilities, adhering to best practices, and performing timely maintenance, you can achieve a high-pressure pipeline that performs flawlessly for years.

Comments