The Face-Shield Packaging Tooling market plays a crucial role in the packaging of face shields, a vital component in personal protective equipment (PPE). With increasing awareness about health and safety, the demand for effective face shield packaging is rising. The tooling used for packaging ensures durability, safety, and compliance with global standards. This market's growth is fueled by the surge in medical and industrial applications, particularly post the global pandemic, highlighting the need for protective measures in high-risk environments.

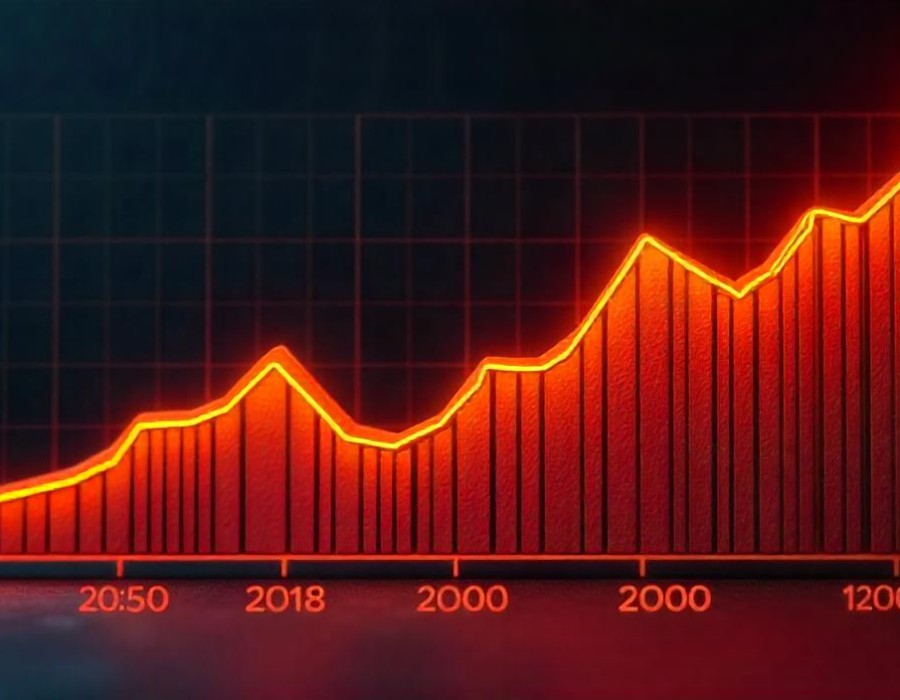

In 2024, the market was valued at around USD 1.2 billion and is expected to expand at a compound annual growth rate (CAGR) of 10.3% from 2025 to 2032, potentially reaching USD 2.3 billion by 2032.

Competitive Landscape

Key players in the Face-Shield Packaging Tooling market include leading manufacturers of packaging machinery, tool manufacturers, and industrial engineers. Companies focus on innovation to provide cost-effective and high-performance solutions. With technological advancements, the industry sees the integration of automation and robotics, improving the speed and precision of packaging. Strategic partnerships, mergers, and acquisitions between machinery developers and PPE producers further strengthen the market's competitive edge.

Growth Drivers

The primary driver for the growth of the Face-Shield Packaging Tooling market is the heightened focus on health and safety. The global response to pandemics, such as COVID-19, has led to an increase in PPE production, especially face shields. As the demand for face shields persists, efficient tooling is crucial to meet the surge. Additionally, the industrial expansion in healthcare, manufacturing, and construction sectors continues to contribute to market growth.

Market Dynamics

The Face-Shield Packaging Tooling market is influenced by various factors, including technological advancements, regulatory compliance, and rising demand for innovative packaging

solutions. Manufacturers are now opting for eco-friendly materials and sustainable packaging to meet the growing global emphasis on environmental responsibility. Also, as face shield designs evolve, packaging tooling adapts to cater to new forms, ensuring optimal protection and cost-effectiveness.

Market Trend

One of the key trends driving the Face-Shield Packaging Tooling market is automation. Automation allows for faster production rates, reduced labor costs, and enhanced consistency in packaging. Moreover, the adoption of artificial intelligence (AI) and machine learning in packaging solutions is on the rise. This technology optimizes packaging processes, predicts maintenance needs, and enhances overall operational efficiency, thereby benefiting manufacturers and end-users alike.

Opportunities

The Face-Shield Packaging Tooling market presents numerous opportunities for growth. With a growing focus on global health crises, new investments in PPE manufacturing facilities have increased demand for tooling solutions. Furthermore, as companies continue to innovate in face shield designs and production processes, there is a need for tooling that can handle these advancements. This includes customized solutions tailored to diverse industries such as healthcare, aerospace, and manufacturing.

Top 5 FAQ

- What is the face-shield packaging tooling market?

- The market involves the production of tools and equipment used to package face shields, ensuring they are safely and efficiently packaged for transport and use in industries such as healthcare, manufacturing, and construction.

- What are the key growth drivers for this market?

- The main drivers include increased awareness of personal protective equipment (PPE) due to global health crises, a surge in face shield demand, and advancements in packaging technology, including automation and AI.

- Who are the major players in the face-shield packaging tooling market?

- Key players include manufacturers of packaging machinery and tooling companies that provide customized solutions for face shield packaging, with major players integrating advanced technologies like robotics and automation into their solutions.

- How does automation impact the face-shield packaging tooling market?

- Automation significantly enhances packaging speed, accuracy, and consistency while reducing labor costs. It is a growing trend that allows companies to meet the high demand for face shield packaging while maintaining quality standards.

- What are the opportunities in the face-shield packaging tooling market?

- Opportunities exist in expanding healthcare, manufacturing, and construction sectors, the increasing focus on sustainability, and the rise of new face shield designs that require customized tooling solutions to improve efficiency and reduce waste.

Comments