Have you ever wondered what goes on behind the scenes of a leading drawer slide factory? From design to production, a factory that produces high-quality drawer slides requires a combination of innovative technology, skilled workers, and a commitment to excellence. In this article, we will take you on a tour of a leading drawer slide factory, giving you a glimpse into the inner workings of a facility that produces some of the best drawer slides in the industry.

Design and Development

The journey of a drawer slide begins in the design and development department. Here, a team of experienced engineers and designers use state-of-the-art software to create innovative and functional designs. They work closely with customers to understand their needs and preferences, ensuring that the final product meets their expectations. The design team uses 3D modeling and simulation tools to test and refine their designs, making sure that the drawer slides are not only functional but also aesthetically pleasing.

Material Selection and Procurement

Once the design is finalized, the next step is to select the materials that will be used to produce the drawer slide factory. The factory sources high-quality materials from reputable suppliers, ensuring that the final product is durable and long-lasting. The procurement team works closely with suppliers to ensure that the materials meet the factory's high standards, and that they are delivered on time to meet production deadlines.

Production

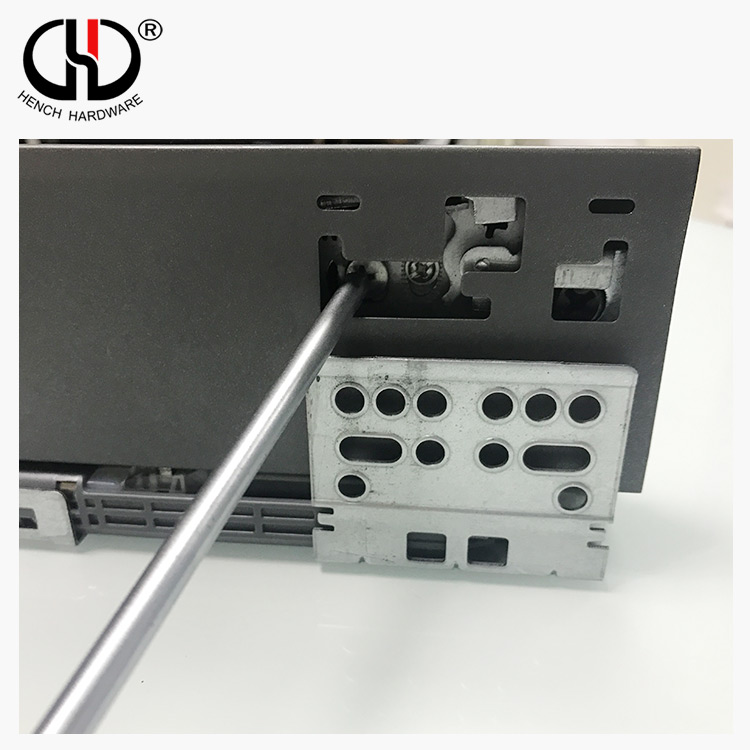

The production department is the heart of the factory, where the designs are brought to life. The factory is equipped with state-of-the-art machinery, including CNC machines, robotic assembly lines, and automated testing equipment. Skilled workers carefully assemble the drawer slides, paying attention to every detail to ensure that the final product meets the highest standards of quality. The production team works efficiently to meet production deadlines, while also maintaining a safe and clean working environment.

Quality Control

Quality control is a critical aspect of the factory's operations. A team of experienced quality control inspectors checks every drawer slide that comes off the production line, ensuring that it meets the factory's high standards. They test the drawer slides for smoothness, durability, and load capacity, and inspect them for any defects or irregularities. Any drawer slides that do not meet the factory's standards are removed from production and reworked or replaced.

Finishing and Packaging

Once the drawer slides have passed quality control, they are sent to the finishing department where they are prepared for shipping. The factory offers a range of finishing options, including powder coating, electroplating, and anodizing. The drawer slides are carefully packaged to prevent damage during shipping, and are labeled with instructions for installation and use.

Research and Development

The factory is committed to continuous improvement and innovation. The research and development team works closely with the design and production teams to identify areas for improvement and to develop new products and technologies. They conduct research on new materials and manufacturing processes, and test new designs and prototypes. This commitment to research and development ensures that the factory stays ahead of the competition and continues to produce high-quality drawer slides that meet the evolving needs of its customers.

Conclusion

A leading drawer slide factory is a complex and dynamic operation that requires a combination of innovative technology, skilled workers, and a commitment to excellence. From design to production, every stage of the process is critical to producing high-quality drawer slides that meet the needs of customers. By taking a glimpse behind the scenes of a leading drawer slide factory, we hope to have given you a better understanding of what goes into producing some of the best drawer slides in the industry.

Comments