When it comes to creating high-quality precision parts for various industries, CNC machining is a widely used manufacturing process. CNC machining allows for the production of complex and intricate parts with a high level of accuracy and consistency. This is especially crucial for industries such as aerospace, automotive, medical, and electronics, where precision and durability are paramount.

Advancements in CNC Machining Technology

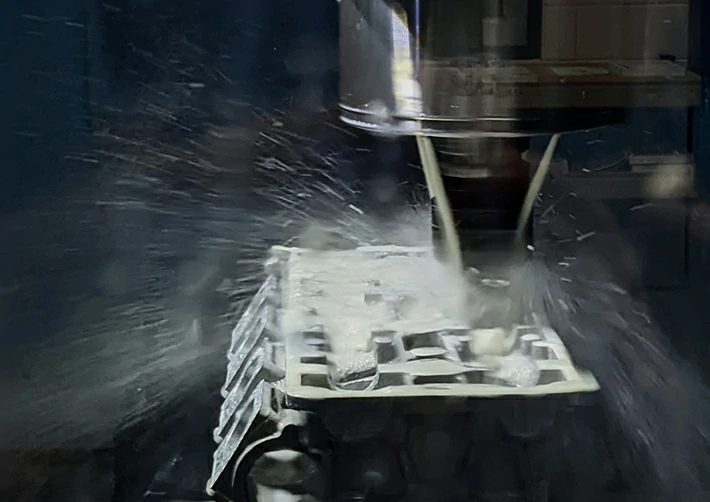

In recent years, advancements in technology have revolutionized the way CNC machining parts are manufactured. With the introduction of advanced software and machinery, CNC machining services can now offer even faster turnaround times and increased precision. These advancements have opened up endless possibilities for improving the performance and durability of precision parts.

Tight Tolerances for Optimal Performance

One of the key advantages of advanced Precision CNC Machining Parts is the ability to create parts with extremely tight tolerances. This means that parts can be manufactured to very exact specifications, ensuring a perfect fit and optimal performance. With advanced software and tools, CNC machinists can produce parts with micron-level precision, allowing for improved functionality and efficiency.

Complex Parts with Intricate Designs

In addition to precision, advanced CNC machining techniques also enable the production of highly complex parts with intricate designs. CNC machines are capable of machining parts in multiple axes simultaneously, allowing for the creation of intricate shapes and contours that would be impossible with traditional machining methods. This level of complexity is essential for industries that require highly specialized parts, such as the aerospace and medical sectors.

Enhanced Durability for Prolonged Lifespan

Furthermore, advanced precision CNC machining can also enhance the durability of parts. By utilizing high-quality materials and cutting-edge machining techniques, CNC machinists can produce parts that are resistant to wear and tear, corrosion, and other forms of damage. This increased durability prolongs the lifespan of parts, reducing the need for frequent maintenance or replacement.

Optimizing Performance through Advanced Software

Another advantage of advanced precision CNC machining is the ability to optimize the performance of parts. By utilizing advanced software and simulation tools, machinists can fine-tune the design and manufacturing process to maximize the functionality of parts. This optimization can lead to improved efficiency, reliability, and overall performance of the final product.

Conclusion: The Benefits of Advanced Precision CNC Machining

Overall, advanced precision CNC machining plays a crucial role in enhancing the performance and durability of precision parts. With its ability to produce parts with tight tolerances, intricate designs, and increased durability, CNC machining services are essential for industries that demand high-quality, reliable parts. By investing in advanced CNC machining techniques, companies can ensure that their products meet the highest standards of performance and durability, ultimately leading to increased customer satisfaction and competitive advantage.

Comments