Laser cleaning systems are transforming industries with their unparalleled precision, efficiency, and eco-friendliness. As a cutting-edge solution for surface preparation and restoration, these systems are replacing traditional cleaning methods such as chemical treatments, abrasive blasting, and manual scrubbing. By utilizing high-energy laser beams, laser cleaning effectively removes contaminants, rust, paint, and other unwanted materials without damaging the underlying surface.

How Laser Cleaning Works

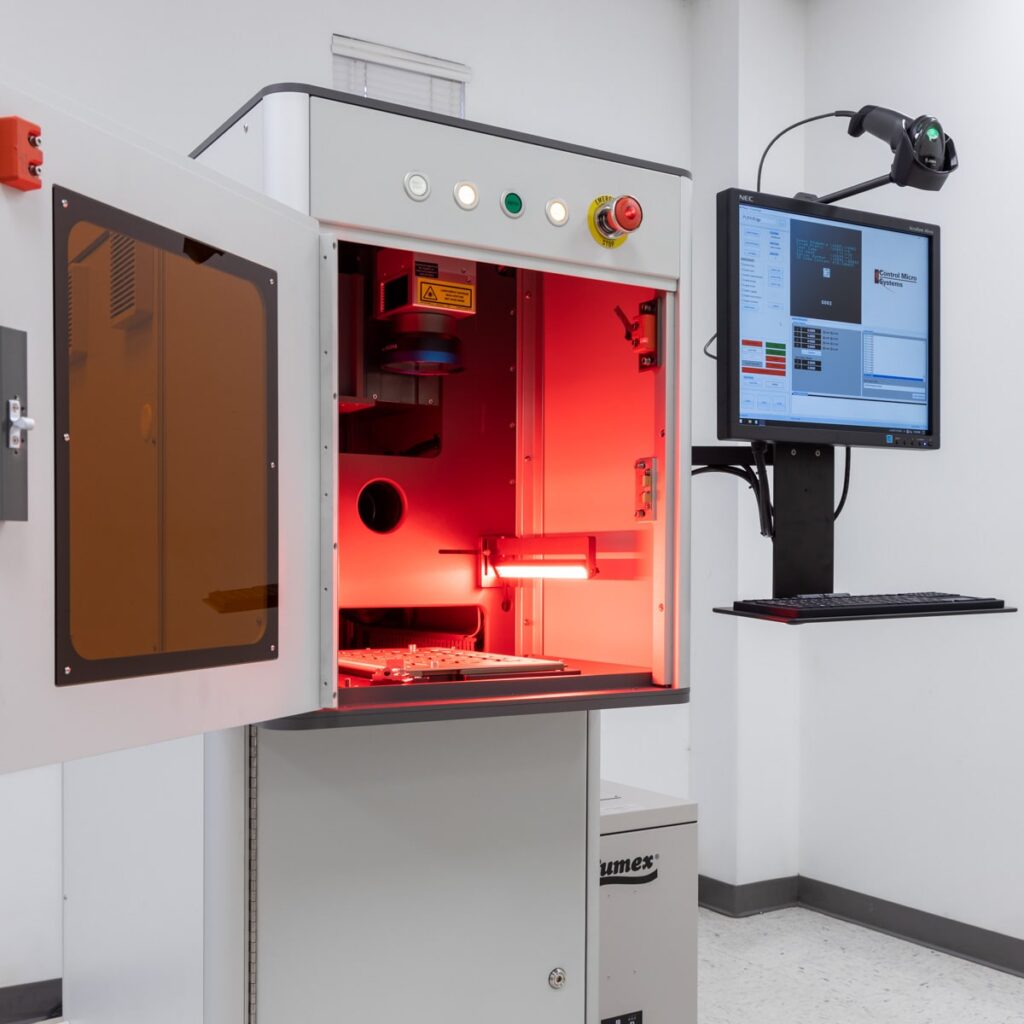

Laser cleaning employs a focused laser beam to irradiate and vaporize surface contaminants. When the laser interacts with impurities, it breaks their molecular bonds and turns them into gas or micro-particles. This process, known as laser ablation, is non-invasive and selective, targeting only unwanted layers while preserving the base material.

Modern Laser Cleaning System are equipped with advanced control options, enabling precise adjustment of power, frequency, and beam diameter to cater to diverse materials such as metal, stone, glass, and composites.

Key Advantages

- Eco-Friendly Solution

- Unlike traditional methods that rely on hazardous chemicals or generate excessive waste, laser cleaning is a dry and clean process. It eliminates the need for solvents and reduces environmental impact significantly.

- Non-Contact and Non-Abrasive

- Laser cleaning ensures zero damage to sensitive surfaces, making it ideal for high-value assets like historical artifacts, aerospace components, and delicate machinery.

- Cost-Effective and Low Maintenance

- While the initial investment may be higher, laser cleaning systems save costs over time by minimizing labor, consumables, and maintenance. Additionally, the systems have a long lifespan and require minimal upkeep.

- Versatility Across Industries

- From removing rust on automotive parts to cleaning molds in manufacturing, laser cleaning is versatile and adaptable. Industries such as automotive, aerospace, electronics, and heritage conservation have embraced this technology for its efficiency and precision.

Applications of Laser Cleaning Systems

- Rust and Paint Removal: Ideal for automotive repair and metal restoration.

- Welding Preparation: Cleans surfaces for optimal welding results.

- Historical Conservation: Safely removes dirt and pollutants from sculptures and monuments.

- Electronics Manufacturing: Prepares surfaces for delicate assembly processes.

The Future of Cleaning Technology

As industries continue to seek sustainable and efficient solutions, laser cleaning systems are becoming a preferred choice worldwide. Innovations in laser technology promise even faster, more precise, and energy-efficient systems in the future.

Whether you’re a manufacturer looking to enhance production processes or a conservationist aiming to preserve history, the laser cleaning system offers a revolutionary way to achieve your goals. With its superior performance and eco-friendly nature, this technology is set to redefine surface cleaning standards.

check out our site for more details.

Comments