In today’s world, safety and functionality are key considerations in building design, automotive engineering, and industrial applications. Laminated safety glass has emerged as a groundbreaking material that meets these demands while maintaining aesthetic appeal. Its unique composition and versatile benefits make it indispensable in modern construction and design.

What Is Laminated Safety Glass?

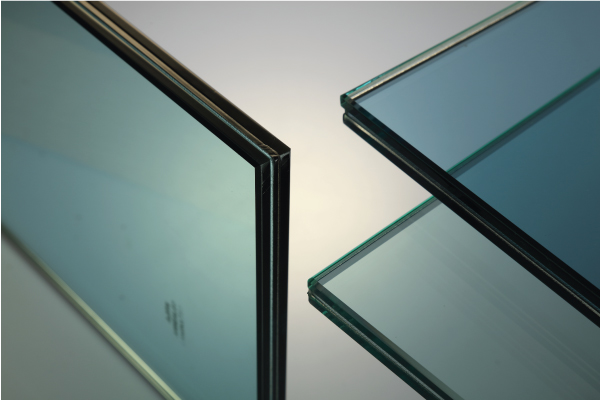

Laminated safety glass consists of two or more layers of glass bonded together with a durable interlayer, typically made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This interlayer ensures that even when the glass breaks, the shards remain adhered to it, preventing them from scattering and causing harm. This safety-first approach has revolutionized how glass is used across industries.

Advantages of Laminated Safety Glass

- Exceptional Safety Features

- Laminated safety glass minimizes the risk of injury during breakage by holding the glass together. This property makes it ideal for homes, offices, and public spaces, where the safety of occupants is a priority.

- Enhanced Noise Reduction

- The interlayer in laminated glass provides excellent acoustic insulation, reducing noise transmission. It is widely used in busy urban areas, airports, and high-traffic locations to create quieter indoor environments.

- UV Protection

- Laminated glass blocks up to 99% of harmful ultraviolet (UV) rays. This feature not only protects people but also preserves interior furnishings, reducing fading and damage caused by prolonged sun exposure.

- Improved Security

- Its shatter-resistant design makes laminated safety glass a formidable barrier against break-ins and vandalism. It is also widely used in areas prone to natural disasters like hurricanes, as it can withstand significant impact forces.

- Energy Efficiency

- By regulating heat transfer, laminated glass enhances energy efficiency in buildings. It keeps interiors cooler in summer and warmer in winter, contributing to reduced energy costs and environmental sustainability.

- Design Flexibility

- Available in various colors, finishes, and textures, laminated glass can be tailored to suit specific design needs while maintaining its safety benefits.

Applications of Laminated Safety Glass

- Residential and Commercial Architecture

- Widely used in windows, doors, curtain walls, and skylights, laminated glass offers both safety and aesthetic appeal. It allows architects to design modern, transparent structures without compromising on security.

- Automotive Windshields

- In the automotive industry, laminated safety glass is standard in windshields. Its durability protects passengers from injuries during accidents and enhances visibility.

- Public and Urban Spaces

- Airports, stadiums, and shopping malls rely on laminated glass to ensure safety and durability while maintaining an open and transparent design.

- Specialized Uses

- Laminated safety glass is also employed in aquariums, soundproof booths, and bulletproof windows, showcasing its versatility in specialized environments.

The Future of Laminated Safety Glass

With advancements in glass technology, laminated safety glass continues to evolve. Innovations such as smart glass integration and enhanced interlayer materials promise to expand its functionality even further. Whether in residential buildings, commercial spaces, or specialized projects, laminated safety glass is poised to remain a key material for years to come.

Conclusion

Laminated safety glass is more than just a building material—it is a testament to how safety and design can coexist harmoniously. Offering unmatched durability, security, and design flexibility, it has become an essential component in creating safe, efficient, and visually appealing environments. As technology advances, laminated safety glass will continue to shape the future of modern design and innovation.

Comments