In environments where static electricity can cause significant damage or pose safety hazards, anti static flooring becomes an essential component of the infrastructure. These specialized flooring solutions are designed to dissipate static electricity, thereby preventing electrostatic discharge (ESD) and ensuring the safety of both personnel and sensitive equipment.

ESD flooring is particularly crucial in industries such as electronics manufacturing, pharmaceuticals, and healthcare, where even a minor electrostatic discharge can result in costly damage to sensitive components or create a risk of explosions in flammable environments. By incorporating anti static flooring, these industries can protect their investments and maintain a safe working environment.

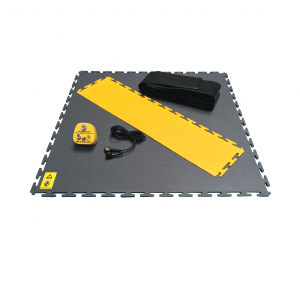

The primary function of anti static flooring is to reduce the buildup of static electricity. This is achieved through a combination of materials and construction techniques that allow the flooring to conduct electrical charges away from people and equipment to a grounded point. Common materials used in ESD flooring include conductive vinyl, rubber, and epoxy coatings. These materials are chosen for their ability to provide a continuous conductive path, ensuring that static electricity is effectively managed.

Installation of anti static flooring requires careful planning and execution. The substrate must be properly prepared to ensure a smooth, even surface, free from contaminants that could interfere with the flooring’s conductive properties. Additionally, grounding systems must be integrated to provide a pathway for the static charges to dissipate safely. Professional installation is recommended to ensure that the flooring meets the required standards and performs as intended.

One of the key benefits of anti static flooring is its ability to prevent costly downtime and equipment damage. In environments where sensitive electronic components are handled, even a small electrostatic discharge can cause significant damage, leading to expensive repairs or replacements. ESD flooring helps to mitigate this risk, ensuring that operations can continue smoothly without interruption.

In addition to its protective properties, anti static flooring is also designed for durability and ease of maintenance. These floors are typically resistant to wear and tear, chemicals, and stains, making them suitable for high-traffic areas and demanding industrial environments. Regular cleaning and maintenance are essential to preserve their effectiveness and longevity.

In conclusion, anti static flooring is a vital investment for industries where static electricity poses a risk to safety and productivity. By choosing the right ESD flooring solution and ensuring proper installation, businesses can protect their assets, safeguard their employees, and maintain efficient operations. Whether in electronics manufacturing, pharmaceuticals, or any other sensitive industry, anti static flooring provides a reliable and effective solution for managing static electricity.

For more info :-

Comments