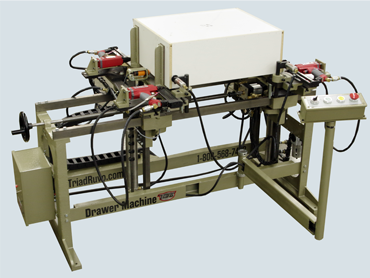

The modern board saw is the machine that modern carpentry shops depend on to cut wood into exactly estimated pieces. Before purchasers can find the right machine for their shop, they should figure out which choices are essential. For example, carpenters should conclude whether a flat saw or an upward saw offers more advantages. A flat saw offers greater flexibility, as timber goes through the table saw while it is on a sliding table, making it simpler to finish edging.

Then again, an upward saw occupies less room on the shop floor. When the shop has figured out which table saw will convey the most worth, they ought to then direct their concentration toward the quantity of frill that can be bought for improving the abilities of this business carpentry apparatus. A few embellishments worth considering following the acquisition of a modern board saw are:

Stand

Most saws accompany a stand with the special case being upward saws and different saws that bolt into the wall. A collapsing stand makes the modern board saw more portable, permitting the shop to move its modern board saw when not being used to let loose space on the shop floor. In a perfect world the stand ought to likewise accompany wheels, as this adds to its portability. On the off chance that the shop buys a modern board saw that doesn't accompany a stand, or buys a stand that doesn't have wheels, then, at that point, it should buy these things to guarantee portability.

Flip Stop

At the point when the administrator of this business carpentry hardware intends to cut different pieces with similar estimations, it ought to gain a flip stop to accelerate the interaction. A flip stop is set at a specific spot, permitting the administrator to finish numerous slices without leading estimations before every one. At the point when various cuts will be made however not all cuts are from a similar position, a fast quit checking pack can be utilized to effortlessly move the flip stop position.

Halfway Wall

This frill makes the administrator's occupation more straightforward by holding that person back from expecting to constantly twist down to make cuts. The halfway wall is intended for making more modest cuts.

Expansion Unit

A little modern board saw is normally less expensive than a bigger saw, so it's a good idea for organizations that seldom need the capacities of an enormous saw to settle on a more modest model. Joining an expansion pack with a little saw makes a bigger base for the wooden board to slide on during cutting. This way shops that seldom need an enormous base can make these cuts with a little saw while setting aside cash and space on the shop floor.

For More Info:-

Commercial steel stud machinery

Comments