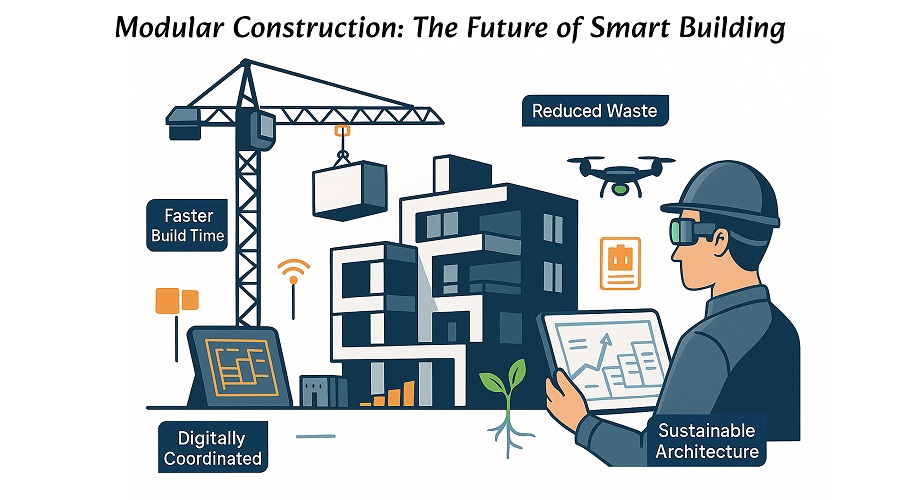

Modular Construction holds the promise of revolutionizing the way buildings are planned, designed, and delivered. Imagine a world where high-rise apartments, hospitals, or office towers are assembled off-site in controlled factory settings and then pieced together on location like giant, precision-engineered LEGO blocks. Thanks to Modular Construction, timelines shrink by up to 50%, on-site disruptions are drastically reduced, and quality control soars to levels unimaginable with traditional methods [1].

This blog explores how Modular Construction merges with smart-building technology to create structures that are not only faster and greener but also more adaptive and connected.

Modular Construction unlocks three transformative advantages in smart building:

- Speed and Predictability. By moving much of the work indoors, construction schedules avoid weather delays and labor shortages. Projects that once took years now wrap up in months, slashing financing costs and accelerating occupancy [2].

- Quality and Safety. Factory conditions allow tighter tolerance, consistent inspections, and fewer on-site accidents. This bolsters both occupant safety and building performance.

- Scalability and Flexibility. Modules can be standardized or customized, making expansions, relocations, or repurposing straightforward, ideal for rapidly evolving urban needs.

Why Modular Construction Matters in Smart Buildings

The appeal of Modular Construction stems from its integration with Internet of Things (IoT) sensors, digital twins, and building management platforms. Each module can arrive pre-wired for power, network connectivity, and environmental controls.

Once assembled, the smart building brain instantly maps every device and data point, enabling real time monitoring of energy use, indoor air quality, and predictive maintenance [3]. Imagine a university dorm that self-optimizes its HVAC operation based on occupancy patterns, all because its modules were designed as intelligent, interoperable building blocks.

Tech Innovations Empowering Modular Construction

Advances in robotics, 3D printing and AI-driven design are supercharging Modular Construction. Automated assembly lines handle repetitive tasks, such as welding frames, installing insulation and routing cabling, while human experts focus on oversight and customization.

AI algorithms analyze digital blueprints to optimize structural layouts and material usage, resulting in a reduction of waste by up to 30% [4]. Meanwhile, digital twin technology creates virtual replicas of modules, stress-tests them under simulated conditions, and refines designs before physical production begins. Such innovations ensure that every module meets exact performance and sustainability targets.

Sustainability and Environmental Impact of Modular Construction

Modular Construction aligns with global sustainability goals. Off-site fabrication consolidates material deliveries, cutting transportation emissions by an estimated 20% [2]. Factory settings facilitate recycling of off-cuts and packaging, driving down waste to nearly zero in some state-of-the-art facilities.

Water usage also drops, as indoor operations reuse and recycle process water rather than relying on on-site concrete curing [4]. When paired with efficient mechanical and electrical systems, modular buildings often surpass green-building certification benchmarks, delivering both environmental stewardship and owner savings.

Challenges and Considerations in Modular Construction

Despite its advantages, Modular Construction also brings distinct challenges. Site logistics necessitate careful coordination to transport large modules through urban corridors, often requiring special permits or temporary road closures. Early design collaboration proves critical: architects, engineers, fabricators, and technology integrators must align on module dimensions, connection details, and smart-system interfaces long before groundbreaking.

Regulatory frameworks in some regions lag behind these innovations, requiring developers to navigate evolving permitting processes. Yet with each successful project, standards bodies and code authorities gain confidence in modular methods.

Real-World Case Studies in Modular Construction

Several landmark projects illustrate how Modular Construction and innovative technology can partner for success:

- St. Bernard’s Hospital, Toronto. Completed 40% faster than a conventional build, its prefabricated patient-room modules arrived pre-equipped with smart beds, nurse-call systems, and environmental sensors. The digital twin has since helped trim energy use by 15% in its first year of operation [3].

- CitizenM Hotels, Amsterdam. Modules arrived fully finished, including bathrooms, furnishings, and IoT climate controls. This approach reduced construction waste by 25% and enabled remote monitoring of guest-room conditions for predictive maintenance [5].

The Road Ahead: Embracing Modular Construction

The future of Modular Construction lies in deeper integration with robotics, edge computing, and renewable energy systems. Self assembling modules could arrive with built in solar panels and battery packs, forming microgrids capable of islanding during grid outages.

AI agents might direct drone inspections of module exteriors and feed data into augmented-reality headsets for on-site technicians.

As standards mature and digital-thread traceability becomes universal, the entire lifecycle from design through decommissioning-will be managed as a cohesive, data-driven process.

Modular Construction is not just a trend; it represents a fundamental shift toward buildings that think, adapt, and evolve. By marrying off-site efficiency with on-site intelligence, it paves the way for more sustainable, resilient, and human-centric urban environments.

Whether for housing, healthcare, or commercial use, embracing this approach today sets the stage for the smart cities of tomorrow.

Unlock the potential of your research with our expert PhD Research Assistant services. Whether you’re a PhD scholar facing thesis challenges or aiming for excellence, we provide end-to-end support to ensure your work stands out. Let us guide you towards academic success your future starts here.

FAQs

1. What is modular Construction?

Prefabricated building sections are manufactured off-site and then assembled on-site.

2. How much faster is it?

Projects often finish up to 50% quicker by overlapping factory work with site prep.

3. Are modular buildings safe?

Yes. Strict factory quality checks ensure they meet standard building codes.

4. Can designs be customized?

Absolutely, layouts, facades, and finishes can be tailored within module dimensions.

5. Is it sustainable?

Yes. Precision fabrication reduces waste and transportation emissions, supporting energy-efficient systems.

References

- Modular Building Institute, “2023 State of the Modular Construction Industry,” 2023.

- McKinsey & Company, “Modular construction: From projects to products,” 2024.

- World Economic Forum, “The Buildings of the Future,” Jan. 2022.

- Turner & Townsend, “Global Construction Report 2024,” 2024.

- National Institute of Building Sciences, “Integrative Design: The Future of Buildings,” 2021.

Comments