Individualized methods of production are required for a diverse range of enterprises and people's personal production endeavors. There are a variety of possibilities available, including locks and fasteners, lightweight building platforms, and others. It is only normal to be interested about the anticipated cost given that each order is customized to the specific requirements of the unique customer. Make use of this information to get a deeper comprehension of the invoicing procedures utilized by fabricators.

Size has a significant impact on the final price of your custom fabrication project. More time and resources are needed to produce larger items. Therefore, their price has increased. Hastelloy flanges manufacturers usually make Inconel 625 flanges.

The sort of metal used to make the custom fabrication item is also a major factor in the final cost. The most common metals in use are stainless steel and aluminum. Depending on the precise nature of the project, other metals like as brass, copper, and tungsten may be used instead. Different alloys, such as chromoly, are often required for customised solutions. Silver, gold, and even platinum might be necessary in some circumstances. There is a lot of renown for titanium pipe fittings manufacturers.

Costs associated with both the raw materials and the finished bespoke fabrication product will be affected by the thickness of the metal sheets employed. The greater the gauge number, the more expensive the metal. Inconel pipe fittings manufacturers are always willing to lend a hand.

Keep in mind that expert fabricators find ways to maximize metal's potential in every project. You can find A105 forged fittings at many places. In addition, they attempt to lessen the kerf, or the amount of metal that is wasted during the cutting process. Without compromising quality, they would do all in their power to reduce the client's costs to a minimum. Hastelloy pipe fittings manufacturers have always done their finest work.

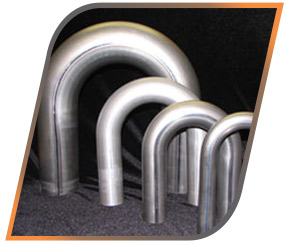

The costs associated with custom manufacturing are very sensitive to the nature of the processes involved. The most frequent methods of working with metal include cutting, bending, rolling, and punching. 3D Pipe Bend is used widely. The process of assembly is ongoing and never ends. There are also a number of situations when welding is required. Overall product pricing is determined mostly by the quantity of required operations, with procedure complexity also playing a role. The more expertise and background you need to do a task, the more it will cost. Alloy steel pipe bend manufacturers often offer the greatest value.

The materials used and the manufacturing processes themselves both have an impact on the durability of steel products. The actual manufacture may be done poorly, reducing the predicted lifetime of your things even if the company has a strong supply chain and works with high-quality components. ASTM A234 WPB Elbow is actually very good. It will be quite expensive to hire such company if the products in question are destined for a project in which longevity is of paramount importance. You should nevertheless undertake some tests to evaluate the company's manufacturing quality before relying on their track record alone. ASTM A234 WPB Bend is indeed excellent.

Comments