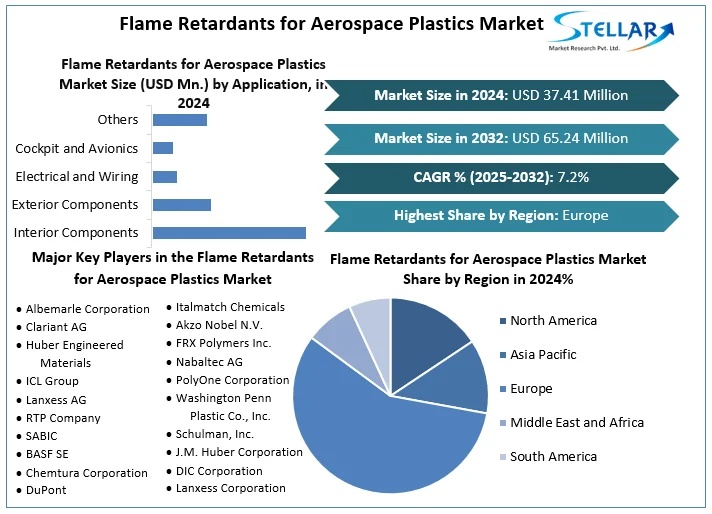

Flame Retardants for Aerospace Plastics Market Size was valued at USD 37.41 Mn in 2024 and is expected to reach USD 65.24 Mn by 2032 at a CAGR of 7.2 % over the forecast period.

Flame Retardants for Aerospace Plastics Market Estimation & Definition

Flame Retardants for Aerospace Plastics Market are specialized additives incorporated into plastic materials used in aircraft to enhance their resistance to ignition and flame propagation. These additives are crucial for ensuring passenger safety, protecting assets, and complying with international fire safety standards in the aerospace industry. The market encompasses various flame retardant types, including halogenated and non-halogenated compounds, tailored to meet the specific requirements of different aerospace applications.

Speak with our Research Analyst:https://www.stellarmr.com/report/req_sample/Flame-Retardants-for-Aerospace-Plastics-Market/1544

Flame Retardants for Aerospace Plastics Market Growth Drivers & Opportunities

1. Stringent Safety Regulations: Global aviation authorities, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), mandate rigorous fire safety standards for aircraft materials. Compliance with these regulations necessitates the use of effective flame retardants in aerospace plastics.

2. Lightweight Material Adoption: The aerospace industry's shift towards lightweight materials to improve fuel efficiency and reduce emissions has led to increased use of plastics in aircraft components. Integrating flame retardants into these plastics ensures they meet safety standards without compromising performance.

3. Technological Advancements: Ongoing research and development efforts are leading to the creation of more efficient and environmentally friendly flame retardant solutions. Innovations in nanotechnology and polymer science are contributing to the development of flame retardants that offer superior performance and reduced toxicity.

4. Growing Aircraft Production: The rising demand for commercial and military aircraft, particularly in emerging economies, is fueling the need for flame retardant materials. As aircraft production scales up, so does the demand for compliant and reliable flame retardant plastics.

Ask for Sample to Know How US Tariff Impacts on Market @https://www.stellarmr.com/report/req_sample/Flame-Retardants-for-Aerospace-Plastics-Market/1544

Segmentation Analysis

By Product Type:

- Antimony Oxide: Widely used due to its effectiveness in enhancing flame retardancy when combined with halogenated compounds.

- Aluminum Trihydrate: Acts as a smoke suppressant and flame retardant, releasing water vapor when heated to cool the material and dilute combustible gases.

- Organophosphates/Phosphorous Compounds: Non-halogenated flame retardants that promote char formation, thereby inhibiting flame spread.

- Boron Compounds: Offer flame retardant properties and are often used in combination with other additives for synergistic effects.

By Application:

- Interior Components: Includes seat cushions, wall panels, and overhead compartments, where flame retardant plastics are essential for passenger safety.

- Aircraft Fuselage: Structural components require flame retardant materials to prevent fire propagation in case of external ignition sources.

- Engine Pylons and Access Doors: Areas exposed to high temperatures necessitate materials with superior flame retardant properties.

- Aircraft Flooring and Wing Edges: Require durable, lightweight, and flame-resistant materials to withstand operational stresses.

By Material Type:

- Carbon Fiber Reinforced Plastic (CFRP): Offers high strength-to-weight ratio and is increasingly used in structural components.

- Glass Reinforced Plastic (GRP): Known for its durability and flame resistance, suitable for various aircraft parts.

- Polycarbonate, Thermoset Polyimides, Acetal/POM, Epoxies, Polyphthalamide (PPA), Polypropylene (PP), Polybutylene Terephthalate (PBT): These polymers are tailored with flame retardants to meet specific application requirements in aerospace manufacturing.

More Information About This Research Please Visit @https://www.stellarmr.com/report/Flame-Retardants-for-Aerospace-Plastics-Market/1544

Country-Level Analysis

United States:

The U.S. leads the global aerospace industry, with significant investments in commercial and defense aviation. The country's stringent fire safety regulations and emphasis on lightweight, fuel-efficient aircraft drive the demand for advanced flame retardant plastics. The presence of major aircraft manufacturers and a robust supply chain further bolster market growth.

Germany:

Germany, as a key player in the European aerospace sector, emphasizes innovation and compliance with EU safety standards. The country's focus on sustainable aviation and the development of next-generation aircraft components contribute to the increasing adoption of flame retardant plastics. Collaborations between research institutions and industry players in Germany foster advancements in flame retardant technologies.

Competitive Landscape

The flame retardants for aerospace plastics market is characterized by the presence of several key players focusing on innovation, strategic partnerships, and expansion to strengthen their market position. Notable companies include:

- Clariant Corporation: Offers a range of flame retardant solutions tailored for aerospace applications, emphasizing sustainability and performance.

- Huber Engineered Materials: Specializes in halogen-free flame retardants, catering to the growing demand for environmentally friendly solutions.

- RTP Company: Provides custom-engineered thermoplastics with integrated flame retardant properties for various aerospace components.

- Italmatch Chemicals: Develops innovative phosphorus-based flame retardants suitable for high-performance aerospace plastics.

- Albemarle Corporation: A global leader in flame retardant chemicals, offering a diverse portfolio for aerospace applications.

- Chemtura Corporation (now part of LANXESS): Provides a broad range of flame retardant additives, focusing on enhancing material safety and compliance.

- DIC Corporation: Engages in the development of advanced flame retardant materials, emphasizing research and development.

- Rio Tinto: Supplies key raw materials used in the production of flame retardant additives for aerospace plastics.

- Royal DSM: Focuses on high-performance materials, including flame retardant polymers for aerospace applications.

About Stellar Market Research:

Stellar Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Stellar Market Research:

S.no.8, h.no. 4-8 Pl.7/4, Kothrud,

Pinnac Memories Fl. No. 3, Kothrud, Pune,

Pune, Maharashtra, 411029

Comments