API 5L X52 grade B pipes are among the most affordable and efficient types of pipes. Two of the various kinds of L360 pipe are welded and seamless. Threaded, bevelled, or plain terminations are available for these API 5L Gr X52 Pipe ends.

The API 5L grade x52 lsaw pipe has excellent corrosion resistance, making it the perfect choice for sour service. In sour wells, sulphur stress corrosion is a common occurrence. The broken-up hydrogen molecules that are created when the hydrogen sulphide gas is heated coat the walls of the API 5L X52 Pipe Material.

This could cause the API 5L Grade X52 Pipe to break or split. API 5L X52 seamless pipes, such as API 5L X52 PSL1 Pipe and API 5L X52 PSL2 Pipe, are not affected by the chemical changes that take place in the X52 Grade Pipe because of their outstanding corrosion resistance.

Additionally, due to the API 5L X52 erw pipe's surface being covered with various materials, including varnish, black oil paint, anti-corrosion oil, etc. The layer formed by the outside coating prevents the API 5L X52 similar material pipe from corroding.

The API 5L X52m pipe can minimise corrosion brought on by rusting by being galvanised. During the galvanization process, the zinc molecules cling to the API 5L X52 PSL2 steel pipes' surface. This surface stops corrosion by protecting Steel X52 Pipe from air oxidation.

Since it is non-combustible, the API 5L X52 welded pipe does not easily catch fire. They could therefore be used in procedures such as the creation of energy from nuclear, thermal, geothermal, and hydroelectric sources.

Other industries that make use of the X52/L360 PSL 2 EN 10225 S355 G15 Norsok Y22 include building construction, mining, sugar, textiles, maritime engineering, and car manufacturing.

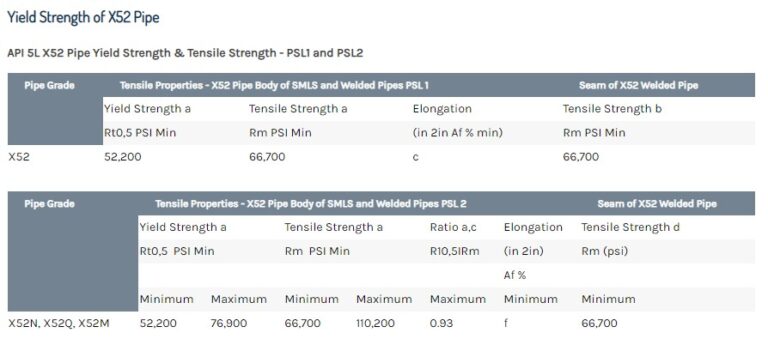

API 5L X52 Mechanical Properties

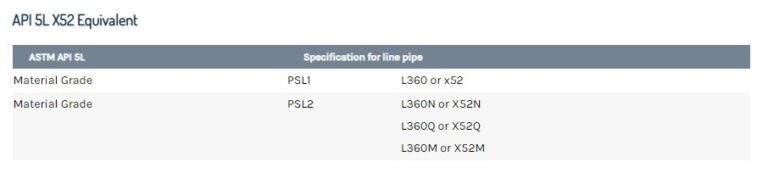

API 5L X52 Equivalent Material

For further knowledge, know more at Eckhardt Steel about various properties and specifications of the product.

Comments