Safety and reliable performance are essential for smooth operations in various applications of electrical connections. BiMetallic connectors are among the top-rated solutions for these requirements. BiMetallic Connectors come with a unique design, composition, and structure, perfectly designed for multiple applications. They are the go-to choice for many professionals, and this blog post will shed light on their properties, applications, and benefits.

Understanding BiMetallic Connectors

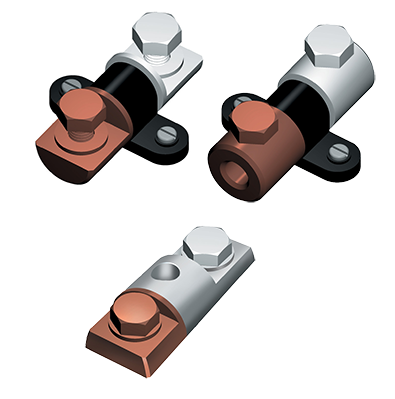

BiMetallic connectors are electrical connectors created by joining two different metal alloys. The two metals are combined through metallurgical bonding techniques that create a molecular-level bond between them. The result of this combination is a connector that takes advantage of both metals' properties. BiMetallic connectors have an excellent ability to resist corrosion, a high tensile strength, and are highly conductive. They come in various shapes, sizes, and configurations, and their application is typically based on the demands of the intended environment.

Properties of Bi-Metallic Connectors

BiMetallic connectors' properties make them stand out in a highly competitive market. They include excellent electrical conductivity due to joining two metals, high tensile strength, and excellent resistance to vibration, thermal and mechanical shock. Additionally, BiMetallic connectors have low contact resistance, excellent corrosion resistance, and can withstand extreme temperatures without losing functionality. These properties make them an ideal choice for applications such as power plants, automotive, rail, construction, aerospace, and marine industries.

Applications of Bi Metallic Connectors

BiMetallic connectors find various applications in industries that demand reliable and safe electrical connections. Power plants connect electrical components that require low contact resistance and high thermal conductivity. In automotive and rail industries, they connect components that require highly conductive connectors that can withstand shock and vibration. The aerospace industry uses BiMetallic connectors for joining various parts, including ground electrical circuits and aircraft.

BiMetallic connectors are used in the construction industry as a connection between grounding systems and lightning protection circuits. In marine applications, BiMetallic connectors are resistant to corrosion from seawater and have high tensile strengths required in harsh marine environments. The versatility of BiMetallic connectors in different applications makes them an indispensable component in many industries worldwide.

Benefits of Bi Metallic Connectors

The benefits of BiMetallic connectors are undeniable and have contributed to their widespread use in various industries. They include high resistance to corrosion, low contact resistance, excellent electrical conductivity, and outstanding strength. The corrosion resistance is particularly important in environments with extreme weather conditions, saline water and are often exposed to corrosive substances. The low contact resistance characteristic ensures minimal power loss in the conduction of electrical current. This loss reduction is essential in applications such as power generation, where even a slight loss can lead to significant inefficiencies. Due to their robust nature, BiMetallic connectors offer secure and dependable connections that withstand harsh environmental conditions.

Conclusion:

BiMetallic connectors are critical in various industries due to their unique properties, outstanding benefits and unmatched performance. They offer excellent electrical conductivity, resistance to corrosion, high strength, and low contact resistance. Their vast versatility and application range makes them an ideal choice in numerous environments, including power plants, automotive, rail, aerospace, construction, and marine industries. BiMetallic connectors' use is expected to grow as they remain the preferred choice for safety and reliable connections in various electrical applications.

Comments