What Are Caliper Disc Brakes?

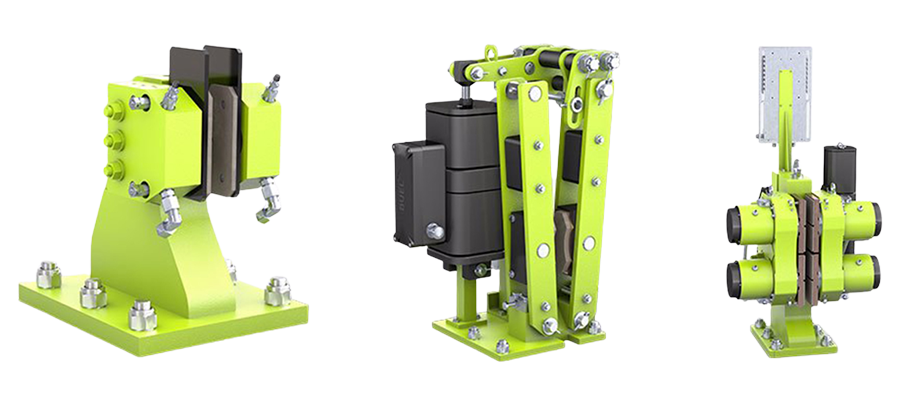

Caliper disc brakes are a crucial component in modern industrial brake systems, widely used in heavy-duty applications across industries such as mining, manufacturing, energy, and marine. They operate using calipers that squeeze pairs of pads against a disc or rotor to create friction, effectively slowing down or stopping the rotation of a shaft or wheel.

Unlike traditional drum brakes, caliper disc brakes offer superior heat dissipation, precise stopping power, and low maintenance requirements, making them ideal for demanding industrial environments.

Types of Industrial Caliper Brakes

When selecting a caliper brake for an industrial application, it’s essential to consider the type that best suits your machinery’s performance needs:

1. Hydraulic Caliper Disc Brakes

These brakes use pressurized hydraulic fluid to operate pistons that push brake pads against the rotor. Hydraulic caliper brakes provide high force output, making them suitable for heavy-duty applications like steel mills, wind turbines, and construction equipment.

2. Pneumatic (Air) Caliper Disc Brakes

These brakes utilize compressed air to drive the caliper mechanism. They are ideal in applications requiring quick response times and where hydraulic systems are not practical.

3. Electromechanical Caliper Brakes

Using an electric actuator, these brakes are perfect for automated systems where precise control and integration with PLCs (programmable logic controllers) are necessary.

4. Manual Caliper Brakes

Typically used in emergency braking systems or machinery that doesn’t run continuously, manual caliper brakes allow for direct user operation.

Benefits of Industrial Caliper Brakes

Superior Performance Under Load

Industrial caliper brakes are designed to withstand high-torque environments and offer reliable braking even under extreme loads. Their robust construction ensures long-term durability with minimal wear.

Heat Dissipation Efficiency

The open design of caliper disc brakes enables better air circulation, which significantly improves cooling performance. This results in reduced brake fade during prolonged use.

Low Maintenance Requirements

Compared to drum brakes, caliper disc systems require less frequent servicing. The easy access to brake pads and fewer moving parts reduce downtime and labor costs.

Modular Configuration

Many caliper brakes are built with modular systems, allowing for custom configurations to match specific application requirements. This flexibility enhances design efficiency and operational safety.

Applications of Industrial Caliper Disc Brakes

Caliper disc brakes are used across a wide array of industries:

- Wind Turbines – For rotor braking and yaw control.

- Steel Mills – To halt heavy conveyor systems.

- Cranes & Hoists – For load control and safety braking.

- Mining Equipment – For controlling large excavators and loaders.

- Marine Industry – For winches, capstans, and propulsion systems.

- Pulp & Paper Machines – For tension control in processing lines.

How to Choose the Right Industrial Caliper Brake

When selecting the appropriate industrial caliper disc brake, consider the following:

- Torque Requirement: Match the braking force to the system’s torque output.

- Application Environment: Consider exposure to dust, moisture, or corrosive elements.

- Mounting Configuration: Choose between side mount, center mount, or flange mount designs.

- Duty Cycle: Evaluate how frequently and under what load the brake will operate.

- Control System Integration: Ensure compatibility with automated systems if required.

Installation and Maintenance Considerations

Proper Alignment

Improper alignment during installation can lead to uneven pad wear and reduced braking efficiency. Always follow manufacturer recommendations for alignment tolerances.

Pad Inspection

Regular inspection of brake pads is crucial. Look for signs of glazing, cracking, or uneven wear. Pads should be replaced before the friction material wears down to the backing plate.

Rotor Surface Maintenance

Rotors should be kept clean and smooth. Deep grooves or warping can affect braking performance and should be addressed through resurfacing or replacement.

Common Issues and Troubleshooting

- Squealing Noises: Often caused by worn-out pads or contaminants like dust and oil.

- Vibration During Braking: Can indicate rotor warping or uneven pad wear.

- Reduced Braking Force: Might be due to air in the hydraulic line or worn pads.

FAQs

1. What is caliper in disc brake?

A caliper in a disc brake system is the component that houses the brake pads and pistons. It squeezes the brake pads against the disc to create friction, which slows or stops the rotation of the wheel or shaft.

2. Which is better, caliper brake or disc brake?

This question often confuses terms. A caliper brake is part of a disc brake system. Caliper-based disc brakes are generally considered more effective than rim brakes (used on bicycles) or drum brakes due to better heat management and performance under load.

3. How much does a disc brake caliper cost?

Prices vary depending on the type, size, and application.

4. How long do calipers last?

Industrial caliper brakes can last 5 to 15 years or longer, depending on operating conditions, maintenance practices, and load factors.

5. Can I replace my calipers?

Yes, calipers can be replaced when worn or damaged. It's important to replace them with Emco Precima or high-quality aftermarket components that match the original specifications for safe and effective braking.

Conclusion

In industrial environments where precision, safety, and reliability are paramount, caliper disc brakes offer a tried-and-tested solution. Their ability to perform under pressure, require minimal maintenance, and adapt to a wide range of applications makes them an indispensable component in modern industrial brake systems.

If you’re designing or upgrading machinery, investing in industrial caliper brakes can ensure long-term efficiency and safety across your operations.

Comments