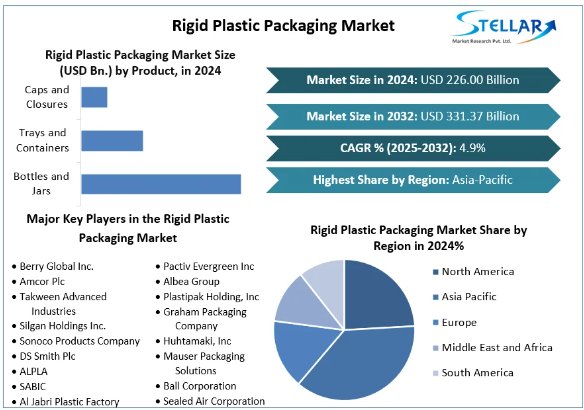

Rigid Plastic Packaging Market size was valued at US$ 226.00 Bn. in 2024 and the total Global Rigid Plastic Packaging Market revenue is expected to grow at a CAGR of 4.9% from 2025 to 2032, reaching nearly USD 331.37 Bn.

Market Estimation & Definition

The global rigid plastic packaging market was valued between USD 226 billion to USD 243 billion in 2024, with projections indicating expansion to USD 331 billion or more by 2032, growing at a compound annual growth rate (CAGR) of approximately 3.2% to 4.9% during the forecast period.

Rigid plastic packaging refers to non-flexible plastic containers and enclosures used across industries such as food and beverages, healthcare, personal care, household, and industrial applications. It includes products like bottles, jars, trays, tubs, drums, and closures made from polymers such as polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS), and polyvinyl chloride (PVC). These materials provide strength, durability, barrier protection, and recyclability, making them vital to modern supply chains.

Get instant access to your sample copy of this report! https://www.stellarmr.com/report/req_sample/Rigid-Plastic-Packaging-Market/1631

Market Growth Drivers & Opportunities

A. Food & Beverage Industry Growth

The primary driver of market growth is the food and beverage sector. Increased urbanization, changing lifestyles, and rising demand for packaged convenience food are accelerating the need for durable, lightweight, and food-safe rigid plastic packaging formats. Ready-to-eat meals, beverages, and perishable goods benefit from the protection and shelf life that rigid containers offer.

B. Expanding Healthcare and Pharmaceutical Usage

The pharmaceutical industry continues to rely on tamper-resistant and sterile plastic packaging for medical equipment, liquid medicines, capsules, and tablets. The growth of chronic diseases, aging populations, and advancements in healthcare infrastructure worldwide are expanding demand for high-barrier, chemically resistant plastic packaging.

C. E-Commerce and Logistics Efficiency

E-commerce growth is fueling demand for protective and lightweight packaging. Rigid plastic formats are widely used due to their ability to safeguard goods during long-distance shipping. They also reduce breakage compared to glass or metal alternatives while keeping costs lower and improving transportation efficiency.

D. Recyclability and Sustainability Push

With increasing consumer and regulatory focus on environmental responsibility, rigid plastic packaging manufacturers are shifting toward recyclable materials, post-consumer resin (PCR), and bio-based alternatives. Recyclability, lightweighting, and reduced carbon emissions are now key competitive advantages.

E. Industrial and Automotive Use Cases

Beyond consumer sectors, rigid plastic packaging is gaining traction in industrial chemicals, automotive parts, and agricultural products. Applications like drums, crates, and spill-resistant containers enable leak-proof storage, handling, and transport of hazardous and non-hazardous materials.

Future Opportunities:

- Bioplastics and recycled resin integration to meet circular economy targets.

- Smart packaging technologies that enable track-and-trace, anti-counterfeit features, and sensor-based freshness indicators.

- Emerging markets in Latin America and Africa with growing consumption of packaged goods.

Segmentation Analysis

By Material:

- Polyethylene (PE) remains the most widely used due to its durability, flexibility, and cost-effectiveness.

- Polypropylene (PP) and PET are gaining adoption in food, beverage, and pharmaceutical sectors for their excellent chemical resistance and clarity.

- Other materials include polystyrene (PS), PVC, and newer bio-based plastics.

By Product Type:

- Bottles & jars dominate the global market, accounting for more than 40% of total rigid plastic packaging sales, especially in beverages, cosmetics, and pharmaceuticals.

- Trays, containers, tubs, closures, drums, and other custom shapes cater to food storage, industrial bulk packaging, and household products.

By Manufacturing Process:

- Injection molding is the fastest-growing segment due to its precision, repeatability, and suitability for mass production.

- Blow molding, extrusion, and thermoforming are also widely used, depending on packaging size, design complexity, and application needs.

By End-Use Application:

- Food & Beverage is the leading segment, driven by demand for packaged dairy, frozen foods, bottled drinks, and processed meals.

- Pharmaceuticals & Healthcare is growing due to drug packaging regulations and rising medical consumption.

- Personal care, household cleaning products, automotive components, and industrial chemicals round out the end-use spectrum.

To access more details regarding this research, visit the following webpage: https://www.stellarmr.com/report/Rigid-Plastic-Packaging-Market/1631

Country-Level Analysis: USA & Germany

United States

The U.S. accounts for the largest share of the North American rigid plastic packaging market, with a valuation estimated around USD 48 billion in recent years. Market expansion is driven by innovations in sustainable packaging, increasing consumption of packaged food, and stringent regulatory standards for healthcare and food safety. Additionally, growth in e-commerce and on-the-go lifestyles increases demand for single-serve, durable packaging formats.

Germany

Germany is a leader in the European rigid packaging sector. With a mature recycling infrastructure and strong environmental regulation, the country emphasizes recyclable and reusable plastic solutions. The demand is particularly high in the food, pharmaceutical, and cosmetics industries. German consumers prioritize eco-friendliness, pushing manufacturers to adopt recycled plastics and biodegradable options.

Commutator Analysis

Understanding the rigid plastic packaging market requires examining the interconnected roles of its key stakeholders:

1. Raw Material Suppliers

These include producers of base polymers such as PE, PP, and PET. Their innovation in lightweight and recyclable materials is foundational to downstream product design.

2. Packaging Manufacturers

Major players manufacture a range of rigid packaging products and are investing in sustainable alternatives, advanced molding techniques, and automation to increase efficiency and meet evolving consumer demands.

3. FMCG Brands & Retailers

These companies dictate design trends, materials used, and packaging format based on branding, shelf appeal, and environmental goals. Their influence pressures manufacturers to offer more sustainable and cost-effective options.

4. Regulatory Bodies

Governments and international regulators are enacting policies to reduce single-use plastics, increase recycling mandates, and standardize material labeling. These shifts are reshaping supply chain practices and R&D focus.

5. Waste Management & Recycling Ecosystems

The effectiveness of rigid plastic packaging recycling is heavily dependent on waste segregation infrastructure, recycling technologies, and consumer participation. In regions with strong circular economy initiatives, rigid plastics are successfully being diverted from landfills.

6. Consumers

End-users influence the market through demand for convenience, safety, sustainability, and transparency. Public awareness campaigns and generational preferences are prompting shifts in packaging type and material source.

The synergy among these actors drives innovation, while also creating friction in areas such as material standardization, cost optimization, and cross-border regulation compliance.

Uncover Trending Topics :

Greece Dry Bulk Shipping Market https://www.stellarmr.com/report/Greece-Dry-Bulk-Shipping-Market/606

Europe Shipping Container Market https://www.stellarmr.com/report/Europe-Shipping-Container-Market/1270

Press Release Conclusion & Strategic Outlook

The rigid plastic packaging market is poised for sustained and diversified growth through 2032. With a market size set to exceed USD 331 billion, supported by steady demand across core industries and innovation in material science, the sector offers strong long-term prospects.

Key Growth Catalysts:

- Urbanization and lifestyle shifts increasing demand for packaged goods.

- Regulatory momentum accelerating the transition toward recyclable and reusable packaging.

- Industrial and pharmaceutical packaging expanding use of high-performance plastics.

- Material innovation enabling lighter, stronger, and more sustainable products.

Challenges Ahead:

- Environmental concerns and plastic bans in certain regions.

- Complexities in establishing global recycling and waste management systems.

- Cost pressures from raw material volatility and compliance overheads.

Strategic Recommendations:

- For manufacturers: Invest in R&D for bio-based and recycled materials; explore automation and digitalization of production.

- For brands: Redesign packaging to optimize recyclability, and enhance consumer education on disposal.

- For governments: Harmonize regulatory frameworks and provide incentives for circular economy practices.

- For recyclers: Scale infrastructure to improve collection, sorting, and processing of rigid plastic formats.

The future of rigid plastic packaging lies at the intersection of performance, design innovation, and sustainability. Businesses embracing this convergence will lead in delivering value to both consumers and the planet.

About Stellar Market Research:

Stellar Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include science and engineering, electronic components, industrial equipment, technology, and communication, cars, and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Stellar Market Research:

S.no.8, h.no. 4-8 Pl.7/4, Kothrud,

Pinnac Memories Fl. No. 3, Kothrud, Pune,

Pune, Maharashtra, 411029

+91 20 6630 3320, +91 9607365656

Comments