Introduction

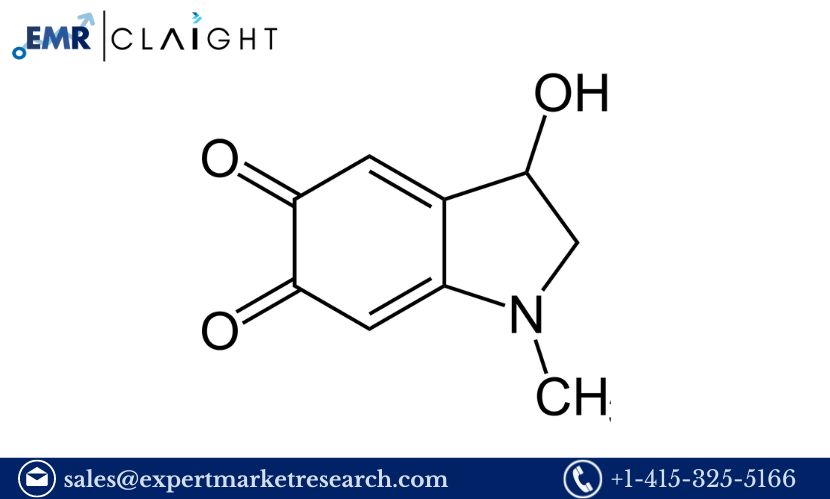

Adrenochrome is a compound of significant interest in various scientific and medical fields. It is a derivative of adrenaline (epinephrine) and has been studied for its potential applications in pharmacology and psychiatry. Despite its controversial and often misunderstood reputation, the compound has been explored for its effects on mental health and its potential as a treatment for certain conditions. This Adrenochrome Manufacturing Plant Project Report provides a detailed overview of establishing a manufacturing plant for adrenochrome. It covers market analysis, plant setup, production processes, and financial projections, offering valuable insights for potential investors, entrepreneurs, and industry stakeholders.

Market Analysis

Demand and Growth Trends

The demand for adrenochrome is relatively niche compared to other pharmaceuticals, primarily driven by:

- Medical Research: Studies into its effects on mental health, including potential applications in treating conditions such as schizophrenia or neurodegenerative diseases.

- Pharmacology: Exploration of its biochemical properties and interactions within the body.

While adrenochrome has a smaller market compared to mainstream pharmaceuticals, its unique properties and potential applications in research can offer growth opportunities. The market is influenced by advances in medical research and changes in regulatory environments.

Competitive Landscape

The adrenochrome market is limited, with few established players. Key factors for success in this niche market include:

- Product Purity: Ensuring high-quality, pure adrenochrome for research and medical applications.

- Regulatory Compliance: Adhering to stringent regulations for pharmaceuticals and research chemicals.

- Innovation: Exploring new research applications and potential therapeutic uses.

Get a Free Sample Report with Table of Contents @

Plant Setup

Location and Infrastructure

Choosing the right location for the manufacturing plant is crucial for efficiency and regulatory compliance. Considerations include:

- Proximity to Research Institutions: Being near universities or research centers can facilitate collaboration and access to cutting-edge research.

- Access to Skilled Labor: Availability of skilled chemists and technicians for specialized manufacturing processes.

- Regulatory Environment: A location with favorable regulations and support for pharmaceutical manufacturing.

The plant should be designed to include:

- Production Area: Equipped with reactors, purification units, and clean rooms for adrenochrome synthesis and processing.

- Quality Control Laboratory: For testing the purity and quality of adrenochrome.

- Warehouse: For storing raw materials and finished products under controlled conditions.

- Administrative Offices: For managing operations, research collaborations, and regulatory compliance.

- Employee Facilities: Including break rooms, restrooms, and safety equipment.

Machinery and Equipment

Key machinery and equipment required include:

- Chemical Reactors: For the synthesis of adrenochrome from adrenaline.

- Purification Systems: Such as chromatography units for isolating and purifying adrenochrome.

- Drying Ovens: For drying and processing the final product.

- Quality Testing Equipment: For analyzing the purity and quality of adrenochrome, including spectrometers and chromatography systems.

Technology and Innovation

Incorporating advanced technology can enhance production efficiency and product quality. Automation, process control systems, and advanced analytical techniques can streamline operations and ensure consistent product performance. Innovation in synthesis methods and research into new applications can also drive growth and competitiveness.

Production Process

Raw Materials

The primary raw material for adrenochrome production is:

- Adrenaline (Epinephrine): The starting compound from which adrenochrome is synthesized.

Production Stages

- Raw Material Preparation: Adrenaline is prepared and purified for use in the synthesis process.

- Chemical Reaction: Adrenaline is oxidized to form adrenochrome, typically using oxidizing agents in a controlled environment.

- Purification: Adrenochrome is purified using techniques such as chromatography to achieve high purity levels.

- Quality Control: Testing the final product to ensure it meets required specifications.

- Packaging and Distribution: Preparing the product for shipment and distribution under strict regulatory conditions.

Environmental Considerations

Adrenochrome production can have environmental impacts, including waste generation and chemical emissions. Implementing sustainable practices, such as recycling by-products, reducing emissions, and using energy-efficient technologies, can help mitigate these impacts and enhance the plant’s environmental responsibility.

Financial Projections

Revenue and Profitability

Revenue potential depends on production capacity and market prices. With a plant producing 100 kilograms of adrenochrome annually, and an average selling price of $10,000 per kilogram, annual revenue could reach $1 million. Effective cost management and strategic market positioning can lead to profitability within 3-5 years.

Funding and Financing

Funding options include bank loans, venture capital, and government grants. A detailed business plan and financial projections are essential for securing financing from investors and financial institutions.

FAQs

1. What is adrenochrome used for?

Adrenochrome is used primarily in medical research to study its effects on mental health and its potential applications in treating conditions such as schizophrenia and neurodegenerative diseases.

2. What are the key benefits of adrenochrome?

Key benefits include its potential use in research into mental health conditions and its unique biochemical properties that may offer insights into various physiological processes.

3. How much does it cost to set up an adrenochrome manufacturing plant?

The cost varies based on plant size, location, and scale. A moderate-sized plant can cost between $7-11 million, covering land, machinery, and initial operating expenses.

4. What are the environmental impacts of adrenochrome manufacturing?

Environmental impacts include waste generation and chemical emissions. Adopting sustainable practices, such as recycling and reducing emissions, can help mitigate these effects.

5. How can I ensure the quality of adrenochrome?

Ensuring quality involves rigorous testing of raw materials and finished products, adherence to manufacturing standards, and continuous improvement practices throughout the production process.

Related Reports

https://www.expertmarketresearch.com/reports/north-america-confectionery-market

https://www.expertmarketresearch.com/reports/astaxanthin-market

https://www.expertmarketresearch.com/reports/weapon-night-sight-market/market-size

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

Comments