LED stands for light emitting diode, which is a semiconductor device that generates light of various colors when current passes through it in the forward direction. High-power LEDs are a form of LED that has more power and brightness than low-power LEDs. This type of LED is an energy-efficient building block that produces appropriate lumen outputs for common lighting applications. They are the greatest solid-state light source for figuring out new lighting concepts.

Advantages of High Power LEDs

Small size, low power consumption, low heat generation, extended life, fast response speed, safe low voltage, good weather resistance, and good directionality. The outside cover can be made of a PC tube, which can endure temperatures as high as 135 degrees and as low as -45 degrees. High power LEDs have the following advantages as a lighting source:

Adaptive

Because of the requirement to consider simplified thermal management, the design procedure for ordinary LED arrays is substantially simpler than that required for high-power technology. High-power technologies necessitate the use of heat sinks and metal-core PCBs to avoid efficiency losses, reduced lifetime, and discoloration caused by high junction temperatures. High-power UV LEDs are easily adaptable for water disinfectant plants.

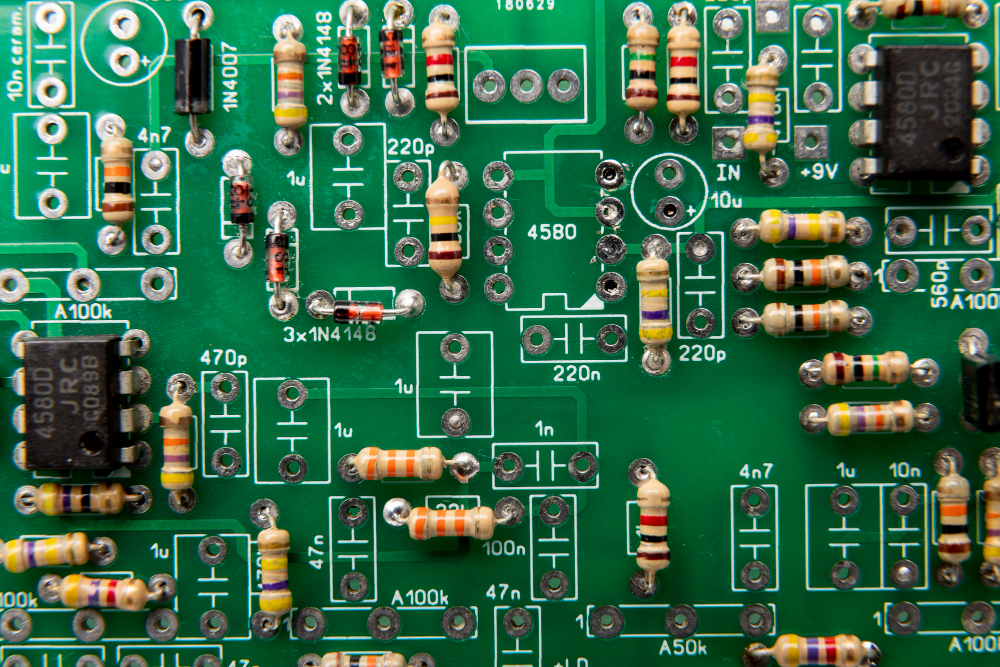

Standard LEDs are easy to design, test, and manufacture because they do not require the use of heat sinks, metal core printed circuit boards (MCPCBs), capacitors, or resistors. This streamlined procedure not only saves time and money in the manufacturing process but also shortens the time to market.

Cost-Cutting

Thermal management is required for high-power LEDs, which may impact the cost of high-power UV LEDs. The heat sink is the most expensive component of the design process. Heat sinks can be composed of a range of metallic materials, ranging from relatively cheap aluminum to more conductive but more expensive materials like copper and silver.

High-power LEDs, on the other hand, necessitate the usage of MCPCBs as another passive cooling solution to manage junction temperature. Because the MCPCB material has superior thermal conductivity, these boards can dissipate heat more efficiently than the less expensive FR4 PCBs used for conventional LEDs.

Space Management

When the device's internal space limits are really large, standard LEDs are frequently the best solution. As previously stated, high-power LEDs necessitate the use of larger heat sinks and, in general, more space-consuming cooling approaches. Its initial job is to increase surface area for convection and radiation cooling. The bigger surface area aids in heat reduction, but it also increases the bulk of the high-power LED. This raises the design obstacles for smaller venues and goods.

Standard LED arrays do not often require the space-consuming drivers, capacitors, and resistors required for high-power LEDs, saving up to 50% of the space. Standard LED arrays can deliver the same brightness as high-power LEDs while taking up less space in space-constrained applications.

Wide Range of Choice

As the technology keeps evolving, brands with efficient UV and various types of LEDs are available every year in the market at a very competitive price. Companies provide products that are adaptive across various sectors with appreciable customer service. Based on proper brand awareness and also individual requirements one makes the best choice that better fits their needs.

Choose LEDs for Efficient Power Consumption

High-power LED is referred to as a "green lighting source" because it is the fourth-generation electric light source. It offers outstanding features such as small size, safe and low voltage, long life, high electro-optical conversion efficiency, fast response speed, energy savings, and environmental protection. It will undoubtedly replace incandescent lamps, halogen tungsten lamps, and fluorescent lamps as a new generation of light sources in the twenty-first century.

Comments