The popularity of Lithium Ion Battery Assembly is easy to understand. As well as being lightweight, they are also long-lasting, and their discharge characteristics are excellent. These batteries aren’t as simple to assemble as they may seem, and the process requires plenty of precautions to keep everyone safe.

Lithium Battery Assembly comes in many different types, and they differ in many ways. The different shapes and sizes of lithium-ion batteries also help them to be distinguish from one another. Lithium-ion batteries differ not only in shape and size but also in voltage and amperage (between 3 and 4 volts, 1 and 2 amps).

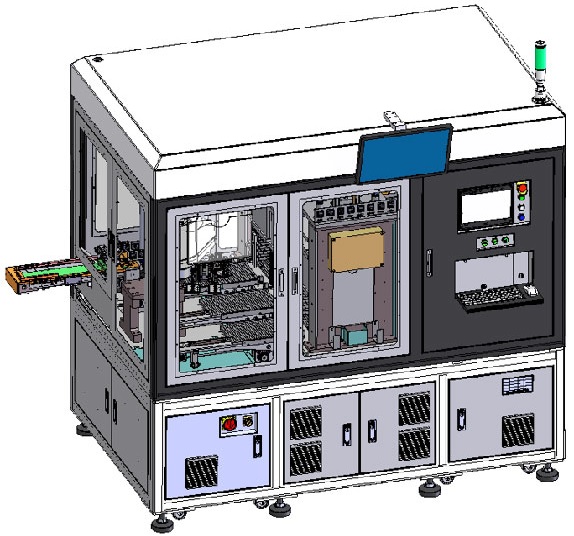

Lithium Ion Battery Assembly Process

All electrodes except the cathode are assemble first, followed by powder coating, then cathode and anode assembly. Each anode sheet and cathode sheet will be punched, stacked into pouches, and then folded with separators into cells. Assembling a lithium-ion battery involves stacking positive electrodes (anode) on negative electrodes (cathode), and pressing them repeatedly until they connect.

Benefits:

1.When lithium-ion batteries discharge, they do not produce gases, so they can be safely use in electronic devices.

2.There is much greater capacity per unit volume with lithium ions than with other metals and liquids commonly used in batteries.

3.Unlike liquid-filled batteries, they charge quickly-in just 10 minutes or less!

4.Moreover, they last for a longer period of time than conventional rechargeable batteries.

Buy the best battery from Battery Manufacturing Machine!

Get To Know More About Us:-

Battery Making Machine | Wine Labeler | Battery Cell Assembly | Battery Machine | Cell Pack Solution

Comments