Moving heavy materials or reaching elevated work areas safely is a constant challenge in fabrication shops, construction sites, and warehouse environments.

Scissor lifters are reliable solutions that combine vertical access and controlled lifting for personnel and materials. They are built to support stability, efficiency, and safety, making them a significant part of today's industrial operations. Scissor lifters include a small slab lifter and a full-height aerial work platform. The selection of the appropriate unit requires that capacity, working height, power type, and serviceability be paired with the daily needs of your workshop.

This article outlines key engineering and operational factors, explores indoor and outdoor applications, and highlights how Tait Sales & Consulting (TSC) is a reliable, shop-focused source for scissor and slab lifters.

Types and Common Uses

Scissor lifters are developed to shift heavy stone slabs vertically with excellent steadiness and control. Their scissor-style mechanism permits perfect handling during lifting and placing, and the automatic locking systems ensure safety and increase the workflow's efficiency. These lifting machines are prevalent in transporting not only marble and granite slabs but also tombstones, concrete barriers, curbs, and median walls. They reduce the need for human lifting, minimize surface damage, and improve the handling procedure.

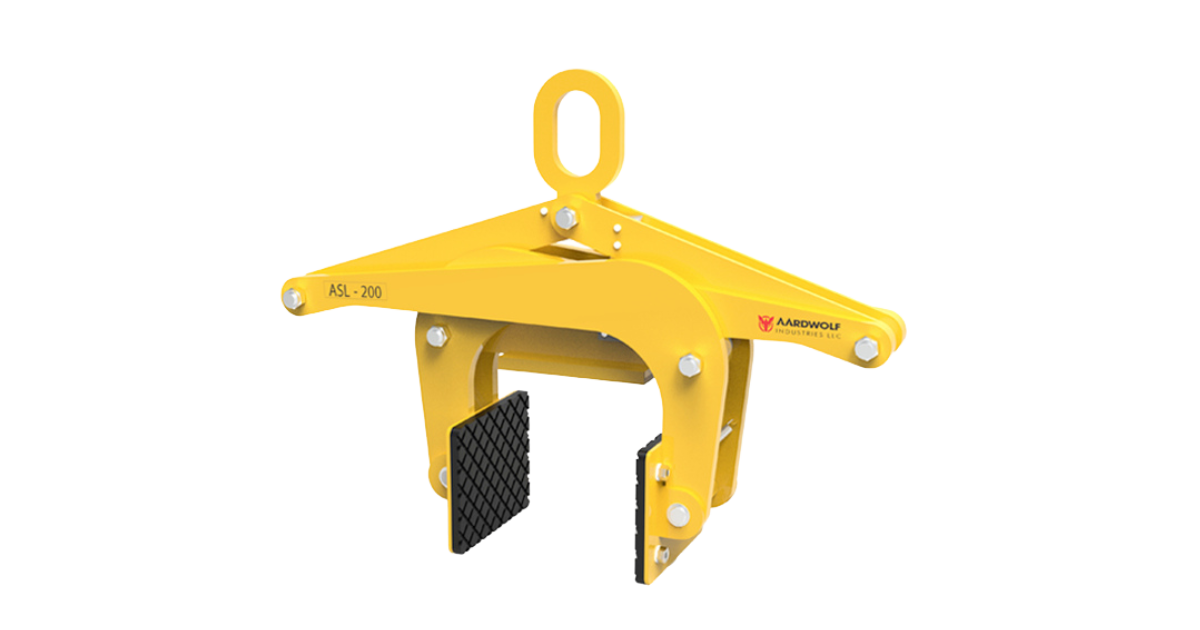

Tait Sales & Consulting (TSC) offers the Aardwolf scissor lifter range, providing multiple grip capacities for slabs, curbs, and precast elements. Each model features:

- Replaceable rubber gripping pads for a secure hold and surface protection

- Gravity-controlled auto-lock mechanisms for hands-free operation

- Heavy-duty, corrosion-resistant frames designed for everyday fabrication facility use

Key Selection Criteria

When choosing a scissor lifter, consider these key factors:

Working Load Limit (WLL)

Choose a lifter rated above the heaviest slab you plan to move. A higher load rating improves safety, reduces mechanical strain, and extends the equipment’s lifespan.

Grip Range and Surface Protection

Ensure the clamp’s opening suits the full range of your slab thicknesses. High-friction polyurethane pads are best for polished materials, as they prevent slipping and surface scratches.

Durability and Maintenance Access

Since fabrication shops demand tough, reliable tools, look for reinforced steel frames, quality welds, and corrosion-resistant finishes. Easy access to service points and replaceable pads or components also helps reduce downtime and repair costs.

Stability and Safety Features

A dependable scissor lifter must keep the load stable during movement. Features like gravity-controlled auto-locking clamps, rubber-lined bars, and centered lifting points protect both operators and materials.

Transportability and Footprint

Consider how easily the unit can move within your workspace. Compact models fit through narrow aisles, while larger lifters may include built-in lifting points or wheeled bases for quick relocation, improving safety and workflow efficiency.

Indoor Applications of Scissor Lifters

Let’s explore how scissor lifters are used indoors and integrated into various workflows.

Warehouses and Storage Facilities

- Load and unload materials in tight or high storage spaces with ease.

- Reposition slabs, pallets, or crates with minimal physical effort.

- High-capacity lifters reduce the risk of product damage and keep workflows efficient.

Manufacturing and Assembly Lines

- Transfer raw materials or components safely between production stages.

- Adjustable platforms fit different material sizes and configurations.

- Streamline processes and increase output by cutting down on manual lifting.

Event and Exhibition Setups

- Position heavy displays, décor, or stage elements with precision and control.

- Adjustable platforms allow quick setup and dismantling.

- Built-in safety mechanisms protect both personnel and materials during handling.

Outdoor Applications of Scissor Lifters

Scissor lifters are equally valuable outdoors, supporting a variety of construction, landscaping, and infrastructure tasks. Common applications include:

Road and Sidewalk Construction

- Offer stable elevation for curb, median, and paving operations.

- Reduce worker strain while improving placement accuracy and speed.

Landscaping and Hardscaping Projects

- Move and place stone slabs, edging, and decorative pieces with control.

- Support heavy loads efficiently while reducing material damage.

Bridge and Infrastructure Maintenance

- Provide safe elevated access for installation, repair, or replacement work.

- Maintain a stable footing when using heavy tools or materials at height.

Pool and Patio Installations

- Assist with positioning decking, stone borders, or large outdoor features.

- Ensure accurate placement while protecting both workers and materials.

Operational Advice From the Field

Good handling habits extend the service life of your scissor lifters and keep every lift safe and predictable.

- Size with margin. Choose a lifter with a grip range and weight rating that exceeds your largest and thickest slabs.

- Replace pads regularly. Worn or hardened gripping pads reduce friction, increasing the risk of slipping or edge damage.

- Inspect before use. Examine welds, latches, and pivot points each day for cracks, rust, or loosened hardware.

- Store properly. Keep lifters in a dry, designated space to prevent corrosion and deformation of pads.

- Train every operator. Even a short, hands-on session in safe clamping, clearance checks, and controlled movement can prevent most workplace incidents.

Why Tait Sales & Consulting Is a Practical Choice

Tait Sales & Consulting (TSC) combines purpose-built slab handling equipment with hands-on industry experience. Our focus is on three key areas:

- Match the lifter to the job. Our team helps you select the right Aardwolf model based on your slab’s thickness, surface finish, and specific handling needs.

- Provide clear specifications and support. Each product page includes detailed grip ranges, working load limits, and construction details, allowing buyers to make confident, informed choices.

- Offer practical workflow guidance. We advise on safe handling, storage, and integration with shop equipment. Our blog and technical resources offer advice on proper use, maintenance, and optimization of equipment for daily operations.

Final Recommendation From the Experts

If your workshop often handles stone, granite, or precast slabs, buying dedicated purpose-built scissor clamp lifters is advisable for safe and efficient material handling. Select a powered scissor lifter with the appropriate platform height and runtime for your installation jobs. Always check the load maps and maintenance schedules before making a purchase, and make operator training a compulsory part of the setup.

Tait Sales & Consulting (TSC) offers a range of durable, high-performance slab lifters designed for accuracy, longevity, and daily use in demanding environments. Our team helps you compare models, select the right grip capacity, and integrate the equipment into your workflow with confidence.

Explore TSC’s Aardwolf scissor lifter range and consult with our team to select the right lifter capacity and grip range for your slabs.

Comments