In today's fast-paced business environment, having complete visibility across your supply chain isn't just advantageous—it's essential. Companies around the globe, including every logistics company in Kolkata and beyond, are discovering how Internet of Things (IoT) technology can transform their operations, providing unprecedented insights and control over the movement of goods from manufacturing to final delivery.

Understanding Supply Chain Visibility Challenges

Before diving into IoT solutions, it's important to recognize the visibility challenges that modern supply chains face. Traditional supply chains often operate with significant blind spots—periods where stakeholders have little to no information about inventory location, condition, or surrounding environment. These information gaps lead to unpredictable delivery timelines that frustrate customers and strain business relationships. When disruptions occur, as they inevitably do, companies lack the real-time data needed to respond quickly and effectively, often resulting in costly delays and scrambling to implement reactive solutions.

Product quality issues frequently go undetected until it's too late, particularly for sensitive items requiring specific environmental conditions. Without continuous monitoring, temperature excursions, rough handling, or contamination can compromise product integrity without anyone knowing until the damage is discovered by the end customer. This problem is particularly acute for companies shipping pharmaceuticals, fresh produce, or sensitive electronics through India's varied climate zones.

For businesses working with a logistics company in Kolkata or any major hub, these challenges are especially pronounced due to the complex nature of urban logistics, port operations, and intermodal transportation requirements. Kolkata's strategic position as a gateway to Northeast India and neighboring countries adds layers of complexity to supply chain management, making visibility not just beneficial but necessary for operational success.

What Exactly is IoT in the Supply Chain Context?

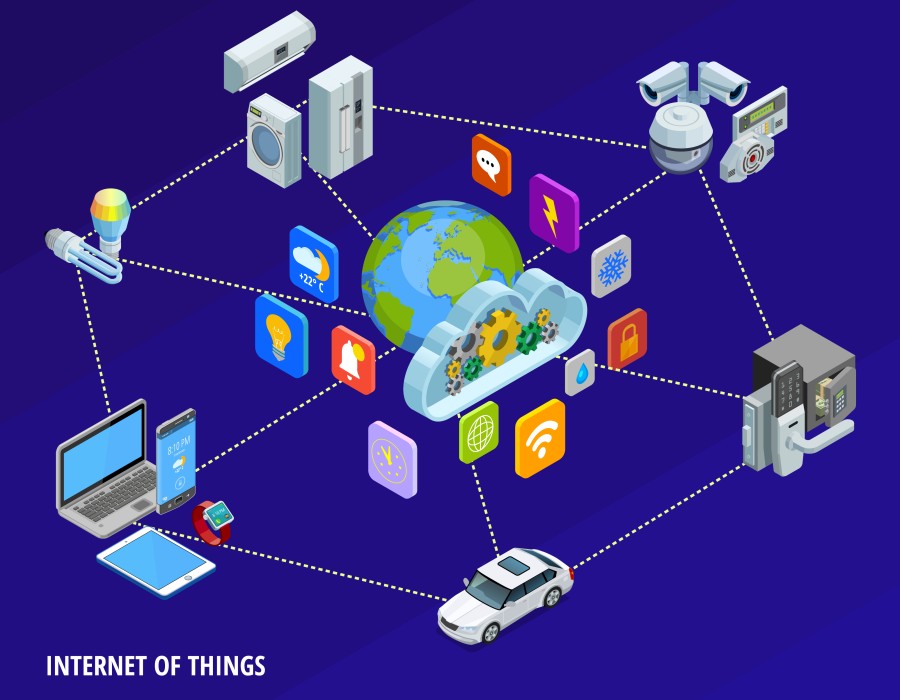

The Internet of Things refers to the network of physical objects embedded with sensors, software, and other technologies that connect and exchange data with other devices and systems over the internet. In supply chain applications, these "things" include shipping containers equipped with GPS and environmental sensors that continuously broadcast location and condition data. Pallets fitted with RFID or Bluetooth technology enable automated tracking through warehouses and distribution centers. Delivery vehicles incorporate telematics systems that monitor not just location but driving patterns, fuel efficiency, and maintenance needs.

Warehouse infrastructure itself becomes "smart" through connected conveyor systems, automated storage and retrieval systems, and environmental monitoring. Even individual product packages can be IoT-enabled through specialized tags and sensors, allowing unprecedented item-level visibility. This interconnected network transforms static supply chains into dynamic, responsive systems capable of self-monitoring and, increasingly, self-optimization.

Transformative Benefits of IoT for Supply Chain Visibility

Real-Time Tracking and Location Services

Perhaps the most immediate benefit of IoT in supply chains is the ability to track assets and shipments in real time. GPS-enabled sensors attached to containers, pallets, or individual packages provide continuous location data, eliminating the uncertainty of where items are in transit. This visibility extends beyond simple location dots on a map—modern IoT systems can provide estimated arrival times adjusted for current traffic conditions, weather disruptions, and port congestion.

When working with the best logistics company in Kolkata, this capability allows customers to monitor their shipments moving through congested urban areas like Howrah or Salt Lake, through busy port facilities at Kolkata Port Trust, or along highway corridors connecting to manufacturing hubs—all from a simple dashboard interface. This transparency transforms customer relationships, replacing anxious phone calls about shipment status with self-service visibility and proactive notifications.

Condition Monitoring for Quality Assurance

Beyond location tracking, IoT sensors can monitor environmental conditions critical to product quality. Temperature and humidity sensors provide continuous data streams that ensure cold chain integrity for pharmaceuticals and perishables. These systems don't just record conditions but actively alert stakeholders when parameters approach critical thresholds, allowing for intervention before damage occurs.

Shock and tilt monitors detect and record rough handling events that could damage sensitive equipment or electronics. When integrated with GPS data, these systems can identify exactly where in the journey handling problems occurred, enabling targeted process improvements. Light exposure detectors protect photosensitive products, while specialized chemical sensors monitor potential contamination for hazardous materials.

This monitoring capability is particularly valuable in eastern India's climate, where temperatures and humidity levels can fluctuate dramatically, especially during monsoon seasons. A logistics company in Kolkata handling pharmaceutical exports to Bangladesh or Nepal can provide documented temperature records throughout transit, ensuring regulatory compliance and product efficacy.

Predictive Maintenance for Equipment

IoT technology enables predictive maintenance for transportation and warehouse equipment by monitoring operational parameters and alerting management before failures occur. For a logistics company in Kolkata managing a large fleet of vehicles navigating challenging urban environments and variable road conditions, this capability can dramatically reduce downtime and extend equipment lifespan.

Sophisticated sensors can detect subtle changes in vibration patterns in truck engines that indicate developing problems weeks before traditional diagnostic methods would catch them. Temperature anomalies in refrigeration units can signal compressor issues before complete failure occurs. Performance changes in warehouse conveyor systems, detected through IoT monitoring, can prompt maintenance before breakdown disrupts operations.

The economic impact of predictive maintenance is substantial. A best logistics company in Kolkata implementing IoT-based predictive maintenance typically sees maintenance costs decrease by 10-40% while equipment downtime reduces by 50% or more. For time-sensitive supply chains, these reliability improvements translate directly to customer satisfaction and competitive advantage.

Automated Inventory Management

IoT-enabled inventory management uses weight sensors, RFID tags, and computer vision to maintain accurate, real-time inventory counts without manual intervention. Traditional inventory management relies on periodic physical counts that are labor-intensive and error-prone. IoT transforms this process into continuous monitoring where shelf systems know their contents, and movement of goods is automatically recorded.

Smart storage systems can track not just quantity but location within warehouses, eliminating the time wasted searching for misplaced items. When integrated with ordering systems, IoT inventory management can automatically trigger replenishment based on actual usage patterns rather than arbitrary reorder points, optimizing working capital while preventing stockouts.

The best logistics company in Kolkata will typically integrate these IoT capabilities with warehouse management systems to provide clients with accurate inventory visibility at all times. For manufacturers in eastern India's industrial corridors, this capability enables just-in-time production with confidence that components will be available when needed.

Enhanced Security and Loss Prevention

Theft, tampering, and unauthorized access represent significant risks in supply chains. IoT devices like electronic seals that report breakage attempts in real time have revolutionized cargo security. These sophisticated seals don't just detect tampering; they record exactly when and where it occurred, providing crucial information for investigations and preventive measures.

Motion detectors and access control systems integrated into warehouse and transportation management create comprehensive security envelopes around high-value goods. Any logistics company handling valuable electronics, pharmaceuticals, or luxury goods understands the importance of these security measures. When unexpected access is detected or a container seal is broken, the system can immediately alert security personnel and provide exact location information.

For cross-border trade through Northeast India, where goods may transit multiple jurisdictions, these security features provide valuable documentation of chain of custody and integrity, simplifying customs clearance and reducing insurance costs due to lower risk profiles.

Implementation Strategies for IoT in Supply Chains

Successfully implementing IoT for supply chain visibility requires careful planning and a phased approach that begins with identifying the most pressing visibility challenges. For some companies, this might be tracking high-value items through high-risk areas. For others, maintaining temperature integrity for perishable goods might be the priority. By starting with focused objectives that address clear business problems, companies can demonstrate value quickly and build momentum for broader implementation.

Device selection should be driven by specific visibility requirements and operating environments. GPS trackers with long battery life might be essential for international shipments, while more economical Bluetooth beacons might suffice for warehouse operations. Environmental sensors should be calibrated to the specific parameters that matter for the products being monitored. When working with a logistics company in Kolkata, it's important to discuss their existing IoT capabilities and how they align with your specific requirements, ensuring compatibility and data sharing capabilities.

Data management represents one of the most significant challenges in IoT implementation. A single container with multiple sensors can generate thousands of data points during a typical journey. Multiply this across hundreds or thousands of shipments, and the data volume becomes enormous. Cloud-based platforms with scalable storage and processing capabilities are essential, as are analytics tools that can transform raw data into actionable insights. The best logistics company in Kolkata will have established data management infrastructures that can integrate with client systems while providing appropriate security and privacy controls.

Integration with existing business systems remains crucial for maximizing IoT value. Standalone visibility solutions provide limited benefit; the true power emerges when IoT data flows seamlessly into ERP systems, customer service platforms, and financial systems. For example, when delay predictions from IoT tracking trigger automatic customer notifications and adjustments to production schedules, the entire business becomes more responsive and resilient.

Real-World Applications in Eastern India

Logistics operations in eastern India face unique challenges that IoT technology is particularly well-suited to address. The region's variable infrastructure quality means shipments often travel on roads of inconsistent condition, through areas with limited connectivity, and in challenging weather conditions. The best logistics company in Kolkata will leverage IoT to navigate these challenges through creative implementations tailored to local conditions.

Port operations visibility transforms efficiency at Kolkata's busy port facilities. IoT-enabled container tracking doesn't just locate containers within vast terminal yards; it provides data on dwell time, handling events, and processing status. This visibility helps prevent congestion and reduces the time shipments spend waiting for processing. For importers and exporters, this translates to faster cycle times and more predictable operations, creating competitive advantage in time-sensitive markets.

Cold chain management for agricultural exports represents another critical application. Eastern India produces significant quantities of mangoes, litchis, and other tropical fruits with strong export potential but strict temperature requirements. IoT temperature sensors ensure that these products maintain optimal conditions from farm to packaging center to export vessel. When working with a logistics company in Kolkata experienced in cold chain management, producers can provide international buyers with complete temperature history, building trust and commanding premium prices for consistently high-quality products.

Urban delivery optimization addresses one of the most challenging aspects of supply chain management in dense urban environments like Kolkata. IoT-enabled route optimization doesn't just plot efficient paths; it dynamically adjusts to changing traffic conditions, construction zones, and delivery time windows. For businesses serving Kolkata's rapidly growing e-commerce market, this capability enables consistent delivery performance even during peak traffic hours or monsoon disruptions.

The Future of IoT in Supply Chain Management

Looking ahead, several emerging trends will further enhance supply chain visibility. The rollout of 5G networks across India will enable faster, more reliable connections for IoT devices, supporting real-time analytics and more sophisticated applications like augmented reality for warehouse operations. The dramatically increased bandwidth and reduced latency of 5G will make video analytics and machine vision more practical for supply chain applications, enabling new quality control and security capabilities.

Artificial intelligence integration with IoT data will move supply chains from reactive to truly predictive operations. AI algorithms analyzing historical IoT data can identify subtle patterns that humans would miss, predicting disruptions before they occur and automatically initiating preventive measures. For example, an AI system might detect weather patterns and traffic data indicating potential delays and automatically adjust shipping plans hours or days before problems materialize.

Blockchain integration with IoT creates immutable records of supply chain events, enhancing trust and transparency among all stakeholders. When IoT devices record a temperature reading or location update, blockchain technology can ensure this data cannot be altered, providing definitive records for compliance, dispute resolution, and quality assurance. For industries with strict regulatory requirements or high-value goods, this combination of technologies provides unprecedented security and transparency.

Conclusion

IoT technology represents a transformative opportunity for supply chain visibility, offering unprecedented insights into the movement and condition of goods throughout their journey. For businesses working with a logistics company in Kolkata or considering partnering with the best logistics company in Kolkata, understanding these capabilities is essential for modern supply chain management.

By implementing IoT solutions strategically, companies can reduce costs, improve customer satisfaction, and gain competitive advantage through superior supply chain performance. As technology continues to evolve, those who embrace IoT-enabled visibility will be best positioned to thrive in increasingly complex and demanding supply chain environments.

Comments