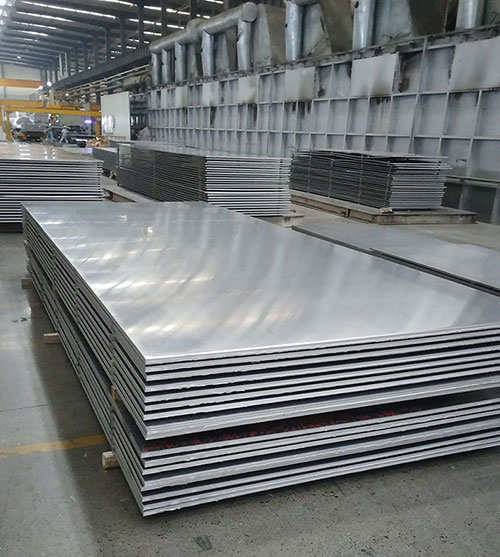

Sachiya Steel International is one of the Leading Stockist And Exporter Of High Quality Inconel Alloy 718 Sheets, Plates and Coils to the customers, which is extensively demanded for its sturdiness and durability. Inconel 718 Sheets has advanced power than Inconel 718 Sheets, which further can be willingly age hardened and worked. Inconel 718 Strip Coils is a nickel-chromium and precipitation – harden able alloy comprising also noteworthy quantities of iron, molybdenum and niobium together by means of smaller amounts of titanium and aluminum. Inconel 718 Coils shows very high tensile, yield, and creep – rupture features at soaring temperatures.

Inconel 718 Plates (UNS N07718) has outstanding creep – rupture potency at temperatures till 1300 Deg F. To perform this function, Inconel 718 Slim Coils must first be solution heat treated (solution annealed is a synonymous term). However, this treatment in Alloy 718 Slating Coils has a tendency to produce notch brittleness in stress rupture. Meanwhile, these Inconel 718 Slating Coils are also being offered in different sizes and shapes to our customers.

Welding of Inconel 718 Perforated Coils in the aged condition will cause the formation of a softened heat – affected zone. Alloy 718 Plates is highly resistant to chloride and sulfide stress corrosion cracking. Typical applications of Alloy 718 Coils in the oil industry are gate valves, choke stems, fasteners, tubing hangers and fire safe valves. We also offer these Alloy 718 Perforated Coils market industry prices.

Alloy 718 Sheets, Plate & Coils Test Certificates

We at Sachiya Steel International provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

Read More: Inconel Alloy 718 Sheets Stockist in India

Comments